sealed bearing IADC 637 tricone bit supplier for hard rock drilling

|

|

|

|

|

|

| Rubber sealed bearing TCI tricone bit | steel tooth tricone bit | PDC bit | PDC drag bit | Hole opener | Replacement cutters |

|

-Traditional and popular TCI bits. -Welcomed by most of regular applications.

|

Features:

-Traditional and popular Milled Tooth bits. -Welcomed by most of regular applications.

|

-Lower WOB& higher RPM than Tricone bit. |

| Basical Specification |  |

|

| Size of tricone bit | 6 1/4" (159mm) | |

| Thread Connection | 3 1/2"API reg pin | |

| IADC CODE | 637 | |

| Bearing type | rubber /metal o-ring journal bearing | |

| Operating Parameters | ||

| WOB (Weight On Bit) | 0.35~1.05 KN/mm (bit Dia.) | |

| Rotary speed | 70~40 r/min / 220~40 r/min | |

| Make up torque | 8.5~12.2 KN.M | |

| Formation | Medium formation with high compressive strength ,and high drillability ,such as mudstone,gypsum,salt,soft limestone,etc. | |

Tricone bit More parameters please click here

|

TRICONE DRILL BITS – STANDARD CONNECTION SIZES |

||

|

SIZE |

STANDARD PIN CONNECTION |

MAKE UP TORQUE |

|

3 1/2 |

2 3/8 API |

4.1~4.7 |

|

4 1/2 to 4 3/4 inch |

2 7/8 API |

6.1~7.5 |

|

5 1/2 to 6 3/4 inch |

3 1/2 API |

9.5~12.2 |

|

7 1/2 to 9 1/2 inch |

4 1/2 API |

16.3~21.7 |

|

9 5/8 to 13 3/4 inch |

6 5/8 API |

38~43.4 |

|

14 5/8 to 26 inch |

7 5/8 API |

46.1~54.2 |

The Metal sealed journal bearing type tricone bit applicataion

|

IADC code |

Applicable Formation |

Main characteristics of the bit |

Recommended parameters |

|

|

Cutting structure |

Normal WOB kN/mm (bit dia.) |

Rotary speed (rpm) |

||

|

117 |

Very soft with low compressive strength and high drillability, such as soft shale , clay and salt bed,etc |

Hardfaced gage and all tooth surfaces, the gage fitted with compacts for enhanced gage protection , and a row of trimmers is added between gage row and heel row |

0.30~0.9. |

300~80 |

|

127 /137 |

Soft with low compressive strength and high drillability, such as sale ,clay,salt bed and soft limestone,etc |

Hardfaced gage and all tooth surfaces, the gage fitted with compacts for enhanced gage protection ,and a row of trimmers is added between gage row and heel row |

0.30~0.9. |

300~80 |

|

427 / 437 |

Very soft formations with low compressive strength and high drillability,such as clay,mudstone,chalk, gypsum,salt,soft limestone, etc. |

Large dia. Offset crested.scoop compacts in inner row,wedge compacts in outer row , high compact exposure, inequable spaced compacts arrangement,and a row of trimmers is added between gage row and heel row |

0.35~0.90 |

280~70 |

|

447 / 517 / 527 |

Soft formations with low compressive strength and high drillability,such as mudstone,gypsum, salt,soft limestone, etc. |

Large dia. Offset crested.scoop compacts in inner row,wedge compacts in outer row , high compact exposure, inequable spaced compacts arrangement,and a row of trimmers is added between gage row and heel row |

0.35~1.05 |

240~50 |

|

537 /547 |

Medium soft with low compressive strength and harder abrasive stringers, such as hard shale, mudstone ,soft limestone and sandstone,etc |

Large radius scoop compacts in inner row, wedge compacts in outer row, inequable spaced compacts arrangement , and a row of trimmers is added between gage row and heel row |

0.50~1.05 |

220~40 |

|

617 /627 /637 |

Medium hard with compressive strength and thick and hard stringers , such as limestone ,hard shale,mudstone and sandstone,etc. |

Conical compacts in inner row,spherical compacts in outer row,and a row of trimmers is added between gage row and heel row |

0.50~1.10 |

220~40 |

|

737 |

Hard formation with high abrasiveness ,such as hard limestone, dolomite, hard sandstone and chert,etc |

Large radius conical compacts in inner row , spherical compacts in outer row , and a row of trimmers is added between gage row and heel row. |

0.50~1.20 |

200~40 |

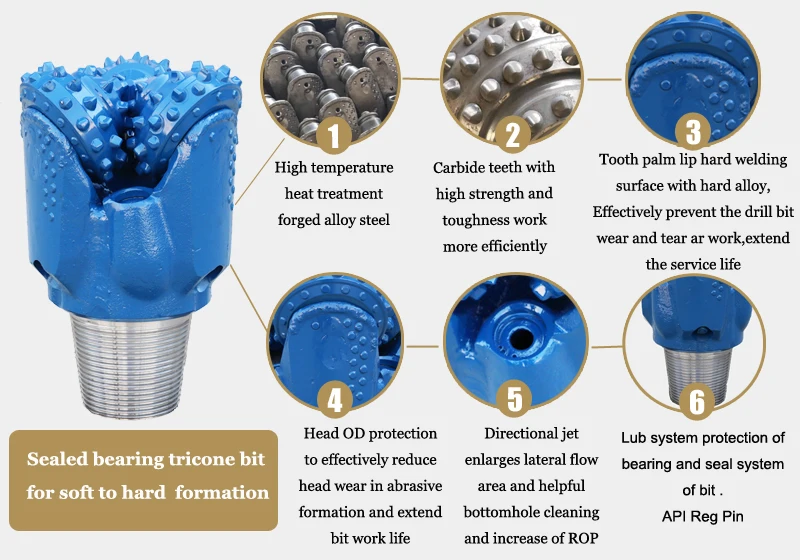

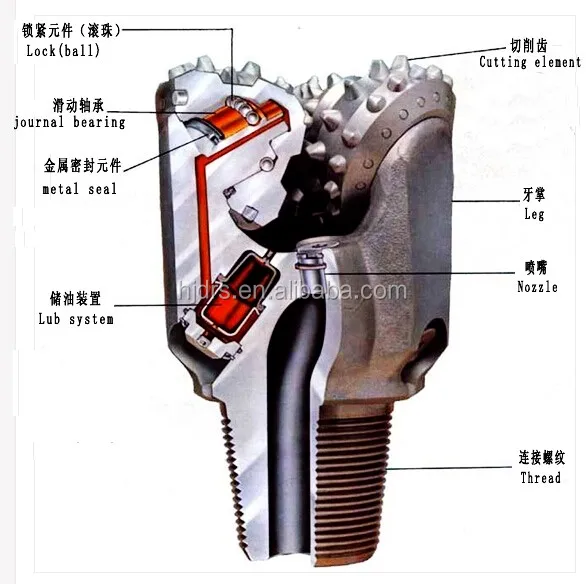

Advantage : 1. High temperature heat treatment forged alloy steel .

2. Carbide teeth with high strength and toughness work more efficiently

3. Tooth palm lip hard welding surface with hard alloy ,Effectively prevent the drill bit wear and tear work

4. Head OD protection to effectively reduce head wear in abrasive formation and extend bit work

5.Directional jet enlarges lateral flow area and helpful bottom hole cleaning and increase of ROP

6. Lubricating system protection of bearing and seal system of bit extend bit work life

7. API REG Connection

8.Rubber sealed and metal sealed bearing

About us

Hejian Deris Petroleum drilling equipment Co., Ltd was established in 2000, located in Hejian City Junziguan Industrial Park, next to National Highway 106, 165 kilometers away from Beijing, close to Tianjin Port, Beijing Airport, convenient transportation and superior location. The company covers an area of 30 acres and a factory building of 15,000 square meters.

Specializing in the production and sales of drilling tools such as Tricone bit, PDC drill bits, Hole opener, roller cone drills, hammer and hammer bit, drill pipes, drill collars, etc. A professional design, production, inspection and foreign trade sales team has been established.

Products are sold to the United States, Canada, Russia, Kazakhstan, Iran, Qatar, Sweden, Germany, Australia, Singapore, Mexico, Colombia and other more than 30 countries. The sales volume reached 15,000 pieces of the roller cone, and the three-cone drill bit 5000 achieved first-class design, first-class manufacturing, first-class product cost performance, and first-class after-sales to achieve win-win for the industry, customers and the company.

Professional team at your service ,2 doctoral professional R&D new technologies, 3 master students’ drawing design, 5 undergraduate graduations. The company inspected the finished semi-finished products, 8 production masters with more than 10 years of experience and several production workers, 6 after-sales service personnel to provide professional technical answers 24 hours a day, 5 website operations and foreign trade personnel to communicate with customers in a timely and efficient manner .

Welcome to visit my factory and inspect the bit quality

Package Type : wooden case ,also be packaged according to customers requirement

Transportation : by sea , by air or land transportation . Less than 50kg shipping by courier better

Delivery : If we have stock, the delivery time will need about 2~3 working days. In general, common size tricone bits and pdc bit, we have stock.

If we have no stock, such as the tci reamer and pdc hole opener, it will be 7-10 working days in total.

This isJenny, already have 6 years working experience for this section. Already make many friends from different countries. I am very pleasure to help them solve some difficult problems for the HDD drilling reamer and tricone bit, and find the more suitable drilling products.

We believe double win is what we want.

If you have any questions, welcome to talk with

Reviews

There are no reviews yet.