polyethylene containers butt fusion Welding Machine for Wastewater treatment systems, Caissons

THIS MACHINE IS OVERWEIGHT,WE CAN SHIP BY SEA OR BY AIR.

THE PRICE IS FOB CHINA,PLEASE TELL US YOUR DESTINATION PORT, THEN WE CAN CONFIRM THE SHIPPING COST.

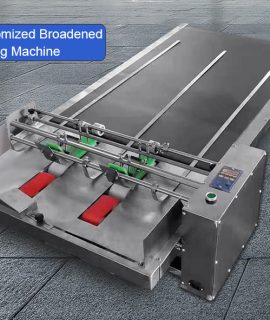

CE Certification Pp Plastic Sheet Welding Machine

1. The electric system is placed in electric cabinet concentrately, so it is convenient for maintenance and check.

2. Press button control makes the operation easy and convenient.

3.The working panel’s material is Q345 manganese, which is featured as non-being heated distortion; The platen’s material is aluminum and for each platen there are two air cylinders providing the power, ensuring the compressive stress is very strong.

4.The heating pipe is inserted through the heating knife, so it is easy and convenient to replace the heating elements. The material of heating knife is imported grade aluminum, with teflon coated. It has the advantage of non-being heated distortion and non-stick.

5.Specially designed rolling device makes the rolling work easy and labor saving.

6.Specially designed LED lights can make you observe the process of welding clearly.

| Specification/Size | SWT-PH2000 | SWT-PH3000 | SWT-PH4000 | SWT-PH5000 | SWT-PH6000 |

| Weldable sheet thickness(mm) | 3.0-30.0 | 3.0-30.0 | 3.0-30.0 | 3.0-30.0 | 3.0-30.0 |

|

Max.working length (mm) |

2000 | 3000 | 4000 | 5000 | 6000 |

|

Roll circle diameter minimum (mm) |

380 | 400 | 450 | 550 | 550 |

|

Air pressure (kg.f /cm2) |

4.0-8.0 | 4.0-8.0 | 6.0-8.0 | 6.0-8.0 | 6.0-8.0 |

|

Energy source (m3/min) |

0.0032 | 0.0052 | 0.0062 | 0.0068 | 0.0075 |

| The rated voltage(V) | 380 | 380 | 380 | 380 | 380 |

| Rated current(A) | 9 | 13.6 | 13.6 | 13.6 | 13.6 |

| Heating Power(KW) | 4kw | 6kw | 8kw | 10kw | 12kw |

| Power of Rolling Motor(KW) | 1.5kw | 1.5kw | 1.5kw | 1.5kw | 1.5kw |

| Heating mode | Overall heating | Overall heating | Overall heating | Overall heating | Overall heating |

|

Drum institutions (parts) |

Optional | Optional | Optional | Optional | Optional |

| External dimensions (L*W*H) mm | 2800*1200*1200 | 3750*1200*1200 | 4850*1200*1200 | 5850*1200*1200 | 6900*1200*1200 |

| Packing dimensions (L*W*H) mm | 3000*1300*1450 | 3900*1300*1450 | 5000*1300*1450 | 6000*1300*1450 | 7050*1300*1450 |

| N.W KGS | 850kg | 1350kg | 1550kg | 1800kg | 1900kg |

| G.W KGS | 1000kg | 1500kg | 1700kg | 1950kg | 2100kg |

| Heating element: Taiwan imported heating knife, the surface is coated with Teflon | |||||

| Device equipped with automatic winding device mechanism | |||||

| Suitable material: PP, PE, PVDF, PVC, PPN, etc. | |||||

| Can be customized according to customer requirements | |||||

| Scope of application: electroplating equipment, environmental protection equipment, chemical containers, sewage treatment, piping, ventilation systems and other industries | |||||

| Size | SWT-PH2000 |

| The rated voltage | 380V,50/60Hz |

| Weldable sheet thickness | 3.0-30.0mm |

| Max.working length | 2000mm |

| Roll circle diameter minimum | 380mm |

| Air pressure(kg.f /cm2) | 4.0-8.0 |

| Energy source(m3/min) | 0.0032 |

| Rated current | 9A |

| Heating Power | 4kW |

| Power of Rolling Motor | 1.5kW |

Automatic plastic sheet hdpe plate butt fusion pp welder machine has three welding function:

1. rolling

2.90 degree welding

3.180 degree welding

APPLICATION:

Manufacture of reservoirs, tanks and containers, manufacture of plastic apparatus, pipeline construction, ventilation systems, serial welding, water treatment systems, scrubbers, environmental technology, swimming pools, transport and logistics.

Reviews

There are no reviews yet.