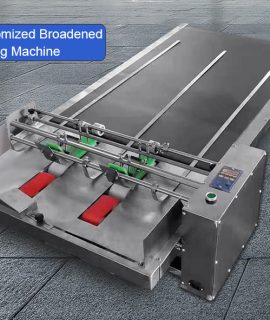

Products Description

Introduction:

Roll Feeding square bottom paper bag making machine forming the paper bag in one processfrom printed or unprinted roll paper ,

side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This

machine controls by PC programmable servo motor through the human-machine touch screen interface. It can produce various of

specifications paper bags. This machine have advantages of high speed, quickly replace the paper bag specifications, more wide

range adjusting etc. It is an ideal machine for producing food bag, shopping handles bag.

side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This

machine controls by PC programmable servo motor through the human-machine touch screen interface. It can produce various of

specifications paper bags. This machine have advantages of high speed, quickly replace the paper bag specifications, more wide

range adjusting etc. It is an ideal machine for producing food bag, shopping handles bag.

Features

1. The human-machine touch screen interface, the work condition can be shown in real- time.

2. Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3. Material lifting adopt pneumatic lift structure.

4. Automatic constant tension control system. The tension will be just right from beginning to end.

5. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

6. Thumb buttons, appressed bottom cutting device, bag type have many choices.

7. Don’t stop machine adjust double bottom structure, the adjustment will become more intuitive, more simple, more time saving.

8. Glue roller air defense coating control, avoid gluing on besmear brushs hub surface directly,

reduce unnecessary trouble.

9. Accurate color tracking system, automatic alarm prompt when color is wrong.

10. Automatic lubricating oil supply system.

2. Equipped with accurate servo motor drive, it makes the machine run steadily and efficiently.

3. Material lifting adopt pneumatic lift structure.

4. Automatic constant tension control system. The tension will be just right from beginning to end.

5. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life.

6. Thumb buttons, appressed bottom cutting device, bag type have many choices.

7. Don’t stop machine adjust double bottom structure, the adjustment will become more intuitive, more simple, more time saving.

8. Glue roller air defense coating control, avoid gluing on besmear brushs hub surface directly,

reduce unnecessary trouble.

9. Accurate color tracking system, automatic alarm prompt when color is wrong.

10. Automatic lubricating oil supply system.

Product Paramenters

|

Type

|

LMD-400+LST-4700R

|

|

Cutting Length

|

150-460 mm

|

|

Bag Length

|

140-450mm

|

|

Bag Width

|

70-280 mm

|

|

Gusset Thickness

|

0-120 mm

|

|

Standard Flap

|

12-20 mm

|

|

Max.Speed

|

500 pcs/min

|

|

Paper Thickness

|

30-80 gsm

|

|

Paper Roll Width

|

220-700 mm

|

|

Max.Roll Diameter

|

1100 mm

|

|

Reel Inner Diameter

|

76 mm

|

|

Printing Color

|

4Color

|

|

Printing Width

|

700 mm

|

|

Printing Length

|

180-800 mm

|

|

Max.Printing Speed

|

80 m/min

|

|

Overprint Precision

|

±0.15 mm

|

|

Thickness of Plate

|

1.7 mm

|

|

Total Power

|

7.5KW

|

|

Optional paste window unit

|

LMD-400B+LST-4700R

|

|

Film Thickness

|

0.02-0.04mm

|

|

Film Width

|

50-180 mm

|

|

The Max Film Diameter

|

450 mm

|

|

Film Inner Diameter

|

76 mm

|

|

Power

|

2 kw

|

|

Weight of Machine

|

5500 kg

|

|

Overall Dimension

|

8520×1550×1850 mm

|

Product packaging

FAQ

1. Who are we?We are based in Zhejiang, China, start from 2006,sell to Domestic Market(00.00%),Africa(00.00%),Southeast Asia(00.00%),South America(00.00%),Eastern Asia(00.00%),Mid East(00.00%),Northern Europe(00.00%),Southern Europe(00.00%),North America(00.00%),South Asia(00.00%),Eastern Europe(00.00%),Oceania(00.00%),Western Europe(00.00%),Central America(00.00%). There are total about 11-50 people in our office.

2. How can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;

3.What can you buy from us?Paper Bag Machine

4. Why should you buy from us not from other suppliers?2000 square meters 5 professional engineers v bottom paper bag machine speed 400 pcs per minute Square bottom paper bag making machine speed 180-260 pcs per minute High speed v sharp paper bag machine speed 700 pcs per minute.

5.What services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW;Accepted Payment Currency:USD,EUR,CNY;Accepted Payment Type: T/T,L/C,Escrow;Language Spoken:English,Chinese.

6、Are you trading company or manufacturer?We are manufacturer, we have our own worker and factory.

Company Profile

About us

About us Ruian Lilin machinery Co., LTD., is a professional paper bag machine manufacturer.It was founded in 2006, since its inception,the company has been committed to the r&d and production of paper bag making machine, constantly introducing new and high technology, combined with market demands and constantly develop new products, higher quality, higher efficiency to meet the market demands.Main products: LSB series roll paper square bottom paper bag machine, LSD series automatic high-speed paper bag machine, LMD series automatic high-speed paper bag machine, LST series flexo printing machine, and other paper bag related supporting products. The products have been sold to Southeast Asia and Europe. , Middle East, Africa, South America and more than 60 countries and regions.Since its inception, the enterprise always adhere to the “technology first, quality first” business philosophy, with honest and trustworthy operating style, excellent product quality and excellent service to win for the principle, for the user to achieve maximum value to reflect my value. Wholeheartedly welcome the domestic and foreign merchants to come to visit or inquire.

Reviews

There are no reviews yet.