- we do air compressors export for 9 years

- we received good quality feedback from all our air compressor customers

- all of our air compressors are passed CE certificate test.

- we accept OEM ODM orders, can make model numbers and logo on our air compressors.

- there is guarantee card with each of our air compressor

Our company offer high quality screw air compressors, oil injection type and oil free type, air receiver tanks, referigerated air dryers, desiccant air dryers, water separator filters, line filters, auto drainer, timer drainer….complete compressed air equipment, with 8 years rich experience in air source industrial, welcome to contact with us if anything related, thank you.

- #sandblastingaircompressor

- 1.0m3/min

- 8bar/0.8Mpa

- 380v/50hz 220v/60hz

- with air tank

- with air dryer and line filters

15kw/20hp 16bar all in one screw air compressor

stock ready to shipp

- 1.3Mpa, 1.6Mpa

- 1.5m3/min/1.7m3/min

- 380v/50hz

- tank 300liters

- air dryer, line filters

- auto drainers

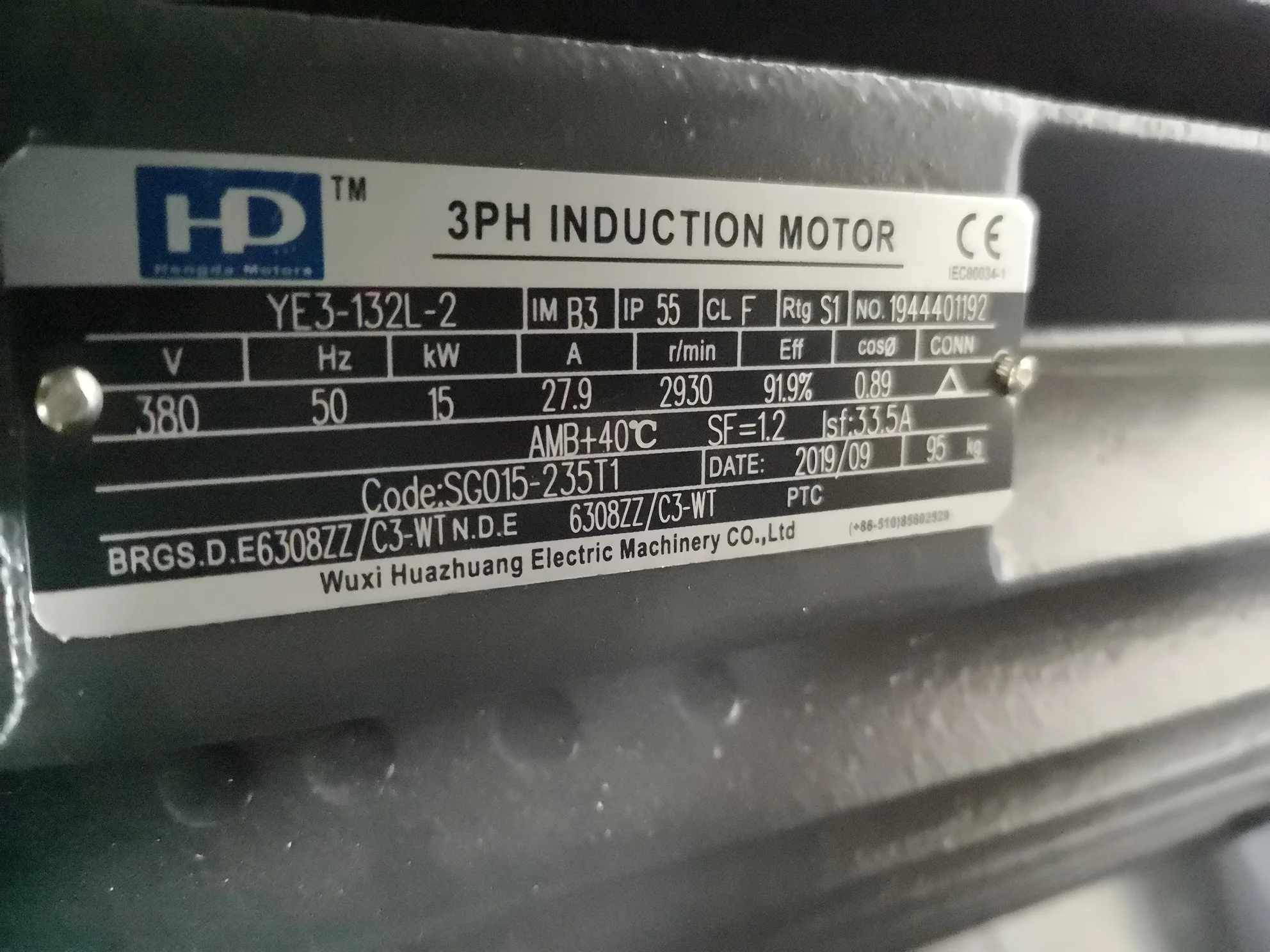

1.3mpa 1.6mpa Screw Air Compressor For Laser Cutting machine

-

Special design for laser cutting machine

-

16bar high pressure special for laser cutting

-

High pressure, high efficiency cutting, air compressor, air tank,

freeze dryer, filter integration

-

Combination of multiple models, so that users can avoid the

trouble of installation, more convenient to use

- 300Liters air tank with timer drainer

- Air dryer

- Air capacity: 2.0m3/min

- Work pressure: 16bar

- Refrigerant: R134

- 4 grand line filters

- Flow rate: 2.0m3/min

- Working pressure: 16bar

- 1).Pre-filter,precision to 3micron

- 2)after-filter,precision to 1micron

- 3)after-filter,precision to 0.01micron

- 4) Active carbon line filter

- 5pcs timer drainer:

Tank mounted with dryer and filter 16bar for laser cutting machine use

Screw air compressor–parameters:

| Model specification |

RMY-10AG | RMY-15AG | RMY-20AG | RMY-25AG | RMY-30AG | RMY-40AG |

| Exhaust volume Exhaust pressure M³/Min Mpa |

0.7/1.3 | 1.2/1.3 | 1.0/0.8 | 2.2/1.3 | 2.6/1.3 | 2.3/0.8 |

| 0.5/1.6 | 1.0/1.6 | 0.9/1.0 | 1.8/1.6 | 2.2/1.6 | 2.0/1.0 | |

| Power/ Horse power |

7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 |

| Exhaust temperature | ≤ Ambient temperature +8℃ | |||||

| Intake temperature | ≤ 45℃ | |||||

| Noise dB(A) | ≤ 68±2 | ≤ 70±2 | ||||

| Oil Content(ppm) | ≈2 | |||||

| L(mm) | 1670 | 1670 | 1670 | 2280 | 2280 | 2280 |

| W(mm) | 850 | 850 | 850 | 930 | 930 | 930 |

| H(mm) | 1570 | 1570 | 1570 | 1920 | 1920 | 1920 |

| Weight(KG) | 516 | 556 | 596 | 756 | 806 | 856 |

| Diameter of outlet | 3/4″ | 3/4″ | 3/4″ | 1″ | 1″ | 1″ |

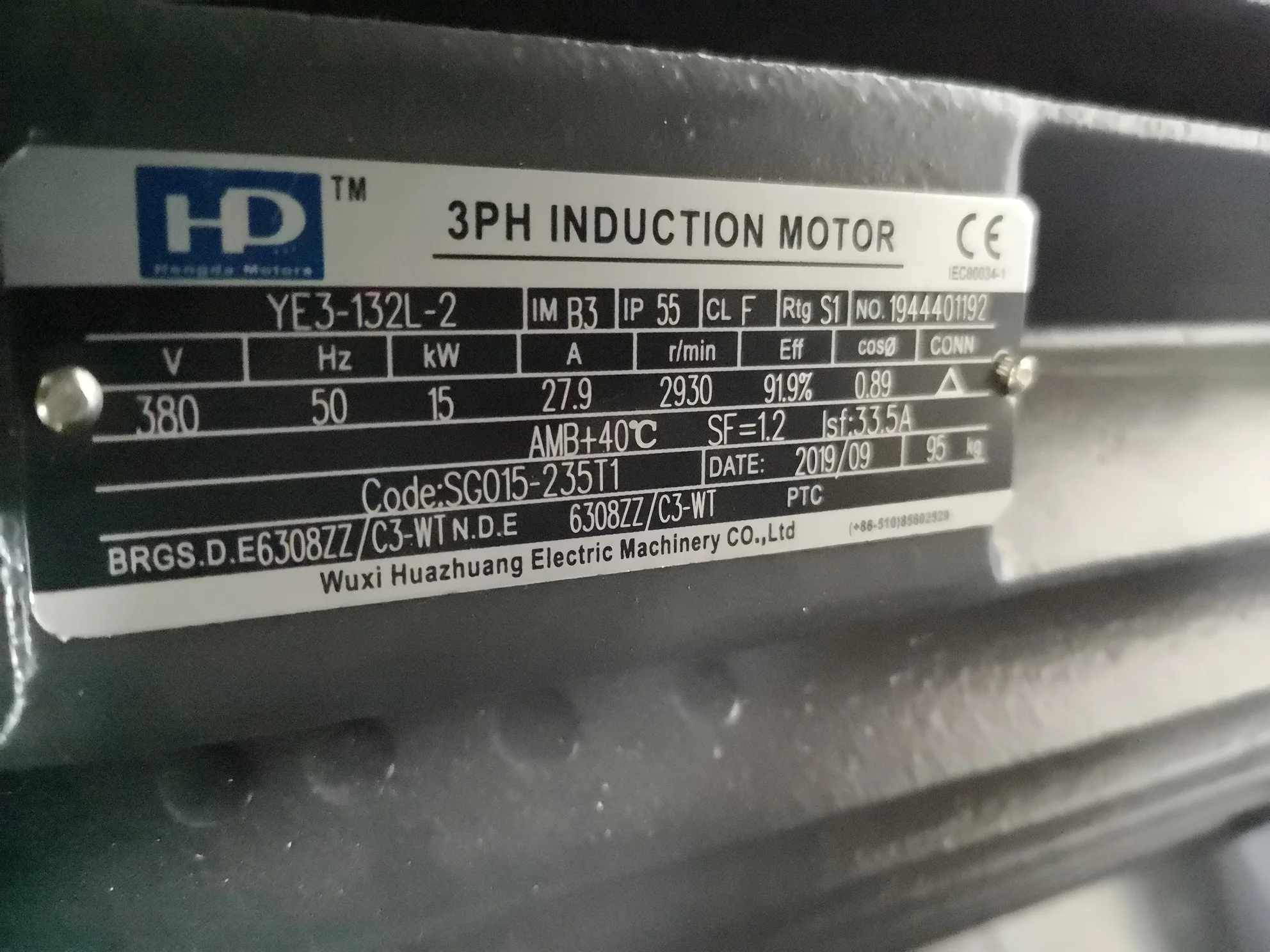

- Compressor Model: RMY-20A/16

- Power: 15kw/20hp IP55/F

- Belt driven/ Air cooling

- Voltage: 220v/380v

- Frequency:50Hz/60Hz

- Work compressor:16bar

- Air capaicty: 1.74m3/min

- Tank: 300liters

- Air dryer: R134

- Line filter: 4 grade

- Timer drainer 5pcs

Compressed air as auxiliary gas:

- For carbon steel plates, when compressed air is used as the auxiliary gas for cutting, the section of the part will generate relatively small burrs. The burrs are not sharp, and can be applied to parts that do not require high cutting surface.

- Stainless steel plate, compressed air is used as auxiliary gas. After the material is processed, the cutting surface will be oxidized. When the cutting section is welded, the oxide will produce slag and pores in the weld bead, which will affect the quality of the weld and cause the strength of the welded part to decrease. Therefore, if the compressed air is used as an auxiliary gas for cutting, and the parts need to be welded after cutting, the oxide layer of the welded part needs to be polished to improve the welding quality; in addition, the oxidation of the cutting surface will become a yellow oxide layer, When re-welding, the oxide layer needs to be polished.

- Aluminum plate and aluminum alloy plate, which uses compressed air as auxiliary gas, will reduce the cutting burr; if using nitrogen, the cutting burr will increase.

Laser cutting three auxiliary gases:

- Laser cutting machine uses different auxiliary gas to cut different materials. The thickness of the cutting material is not used, the pressure of the auxiliary gas and the required flow rate are different.

- There are three kinds of auxiliary gas for laser cutting machine, laser gas, compressed air, auxiliary gas

Laser gas: the gas used to generate laser in the laser generator

Compressed air: generally used to protect the optical path, can also be used as auxiliary gas

Auxiliary gas: gas ejected from the cutting nozzle of the cutting machine

- Oxygen for carbon steel cutting is generally required to have a purity of 99.5% or higher. The main function is to support combustion and blow off the cut melt. The pressure and flow rate vary according to the requirements of the cutting machine manufacturer. It is related to the size of the cutting nozzle model and the thickness density of the material. The general pressure requirement is 0.3Mpa-0.8Mpa, the flow rate is not fixed, such as cutting 22mm carbon steel, and some manufacturers require 10m3/h (including the use of oxygen (Protect double-sided cutting nozzle).

- Nitrogen is used for cutting stainless steel to prevent oxidation reaction and blow off the melt. The purity of nitrogen is particularly high (stainless steel with a thickness of more than 8mm, the purity must reach 99.999%), and the pressure is generally above 1.0Mpa. If you want to cut For stainless steel above 12mm or 25mm thickness, the pressure requirement will be 20Mpa or higher. The flow rate is determined according to the type of cutting nozzle. Generally 12mm thick stainless steel, the flow rate needs 150m3/h, and the thickness is 3mm stainless steel plate, the flow rate is 50m3/ h.

PLC controller functions of our screw air compresosr:

1. Touch screen display shown

- loading and unloading status

- working hours

- current pressure, temperature

- full-load operation hours

- filters and oil replacement time

- running status

- motor running status

- main motor currency

- electric current

- cooling fan current

- cooling fan operation status

2. Automatically alarm functions:

- high temperature alarm

- oil change-over time arrive alarm

- air filter change-over time arrive alarm

- pressure, temperature sensor fault alarm

- oil filter change-over time arrive alarm

- oil separator change-over time arrive alarm

- communication fault alarm

- belt extended use alarm(belt driven compressor)

Fixed Speed Belt driven screw air compressor for laser cutting machine–parameters:

| Model No. | RM-10AG | RM-15AG | RM-20AG | RM-25AG | RM-30AG | RM-40AG |

| Air capacity (m3/min/Mpa) | 0.7/1.3 | 1.2/1.3 | 1.7/1.3 | 2.2/1.3 | 2.6/1.3 | 3.6/1.3 |

| 0.5/1.6 | 1.0/1.6 | 1.5/1.6 | 1.8/1.6 | 2.2/1.6 | 3.2/1.6 | |

| Power(KW/HP) | 7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 |

| Noise dB(A) | 68±2 | 70±2 | ||||

| Length (mm) | 900 | 900 | 900 | 1290 | 1290 | 1290 |

| Width (mm) | 850 | 850 | 850 | 900 | 900 | 900 |

| Height(mm) | 940 | 940 | 940 | 1190 | 1190 | 1190 |

| Weight(Kg) | 230 | 262 | 292 | 450 | 500 | 600 |

| Outlet size | 3/4″ | 3/4″ | 3/4″ | 1″ | 1″ | 1″ |

- Special design for laser cutting machine

-

16bar high pressure customized for laser cutting industry

-

High pressure,high efficiency cutting

Permanent magnet Screw Air Compressors–16bar for laser cutting machine use

Stationary type–parameters

| Model No. | RM-10AM | RM-15AM | RM-20AM | RM-25AM | RM-30AM | RM-40AM |

| Air capacity (m3/min/Mpa) | 0.7/1.3 | 1.2/1.3 | 1.7/1.3 | 2.2/1.3 | 2.6/1.3 | 3.6/1.3 |

| 0.5/1.6 | 1.0/1.6 | 1.5/1.6 | 1.8/1.6 | 2.2/1.6 | 3.2/1.6 | |

| Power(KW/HP) | 7.5/10 | 11/15 | 15/20 | 18.5/25 | 22/30 | 30/40 |

| Noise dB(A) | 68±2 | 70±2 | ||||

| Length (mm) | 900 | 900 | 900 | 1290 | 1290 | 1290 |

| Width (mm) | 850 | 850 | 850 | 900 | 900 | 900 |

| Height (mm) | 940 | 940 | 940 | 1190 | 1190 | 1190 |

| Weight (Kg) | 245 | 280 | 312 | 480 | 530 | 630 |

| Outlet size | 3/4″ | 3/4″ | 3/4″ | 1″ | 1″ | 1″ |

Long interval maintenance periods:

Nearly ideal isothermal compression, direct driven method, smart configuration and precision component design and machining, long bearing service life, all of the above essentially extends interval between regular periodical maintenance.

Shanghai Royal Machinery Co.,Ltd is a high-tech enterprise which specialized in sales and service of compressed air system equipment, and after-treatment equipment, booster compressor, diesel generator and drying equipment, etc.

We have an experienced team. It not only provide high-quality and high-efficiency compressors for users but also provide the best solution for air system equipment during before-sale, selling and after-sale.

Welcome to contact us for inquires and quotation.

All of our screw air compressors are packed by export standard plywood case:

Because of screw air compressor package volume and weight, most of our screw air compressors are shipped by sea.

Wecome to contact us for more details, we will offer compressor details, oil free screw air compressor use manual, oil free screw air compressor configuration list, oil free screw air compressor instruction drawings, spare parts list, installation drawings, technical support and maintenance training.

Our CE certificate:

Air compressors can be grouped into three classifications: consumer grade, professional grade and industrial grade.

- Consumer grade air compressors can be described as a pancake or single-stage model. They’re used for household tasks like inflating tires and inflatable products and possibly some low-load air tools like staplers and brad guns.

- Professional grade air compressors provide more power and higher pressurized air. They could be two-stage reciprocating models or rotary screw models and can provide more power to run several air tools at once with intermittent use.

- Industrial grade air compressors will be the workhorse of a manufacturing plant or the reliable power source on an oil rig. They are designed to provide a steady flow of compressed air for long periods of time and can take fluctuating surges in use typical in major manufacturing plants. These compressors are built with high-quality components that allow for customization to the specific environment to improve performance, energy efficiency and reliability.

Here we offer i screw air compressors:

Power range: 5kw-400kw

Air flow: 1m3/min-75m3/min

#screwaircompressor

#scrollaircompressor

#pistonaircompressor

#oilfreeaircompressor

#oilinjectonaircompressor

#permanentmagnetvsdscrewaircompressor

#fixedspeedscrewaircompressor

#differentapplicationindustrialscrewaircompressors

#lasercuttingaircompressor

#allinoneaircompressor

#compactaircompressor

Welcome to container with us for more details

Reviews

There are no reviews yet.