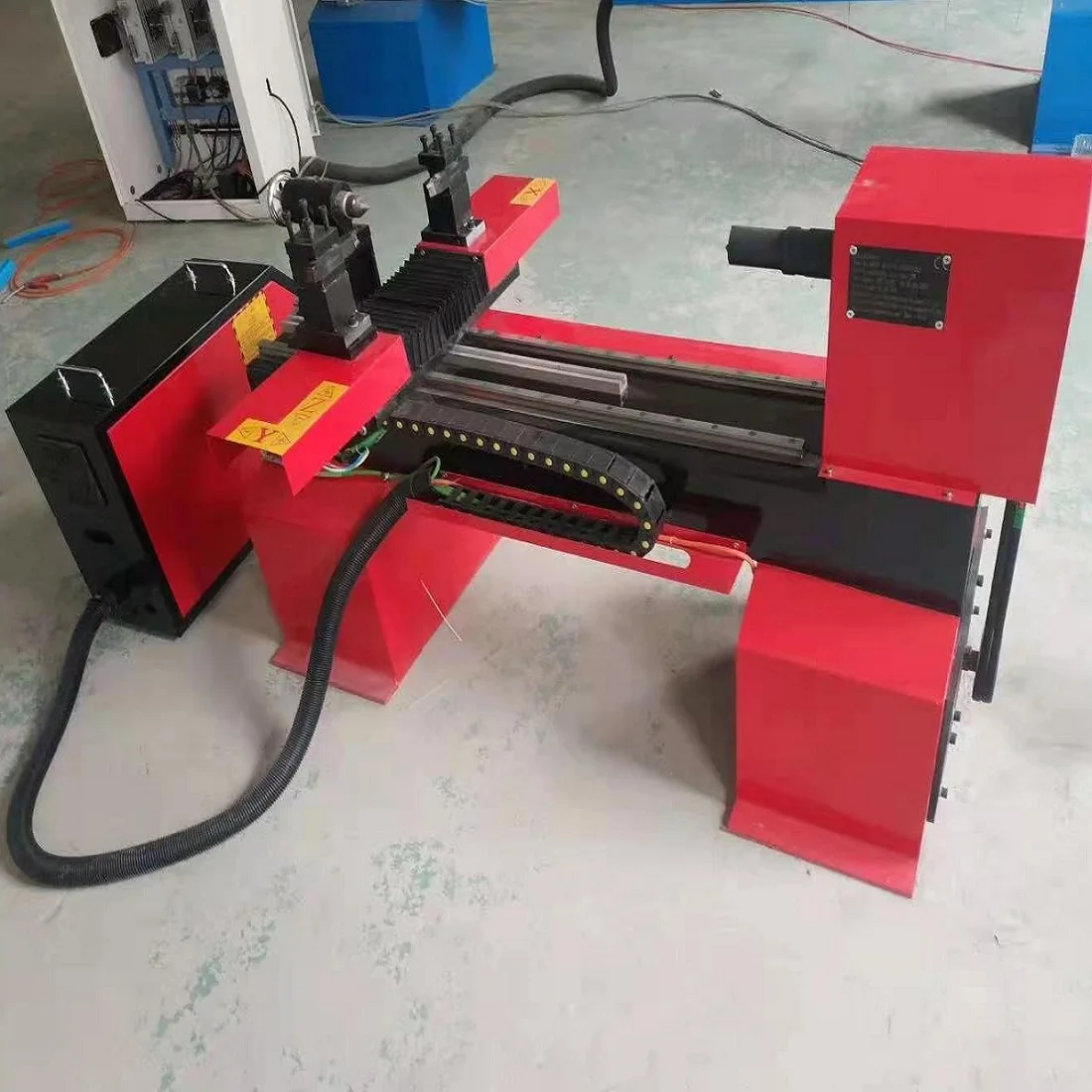

Application Of Wood Bead Making lathe

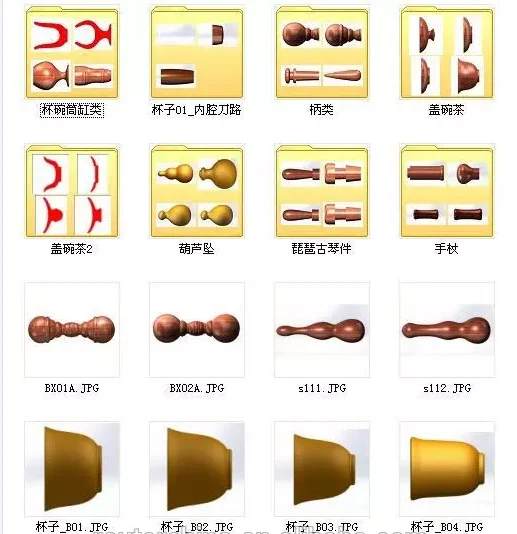

Bead, barrel, all kinds of buddha head pagoda, gourd pendant, hoist pieces, wood rhinoceroshorn cup, bowl, whip,cigarette holder, eggs,ashtray, scroll painting head.

Advantage Of Wood Bead Making lathe

1.It is computer nemerical controled

2.It is with 300 kinds drawing gallery except for round beads

3.Easy controled special wood beads machine control system is studied by us

4.Best hard alloy wood lathe cutter in China market, can match with you soft wood cutter and hard wood cutter

5.Can designed by your requirement

6.Imported square orbit and ballscrew transmission

7.Long lifespan, high precision

8.Processing precision: 0.01mm

Operate way Of Wood Bead Making Lathe

1.Input required drawing in the software

2.Set Bead diameter, select the shape, size.

3.No programming, easy to use.

4.You can also design your own style, drawing of contour line, also can support BMP, JPG etc format

Processing Speed Of Wood Beads Making Lathe

For example:

1.2 size beads shall prevail, Lobular Rosewood automatic Hole, 38 seconds per piece , 30 seconds without holes.

2.Phoebe play hole turning 25 seconds per piece,19 seconds without punching;

3.5cm diameter handball, 2 minutes one piece.

4.5cm diameter and 11cm length hand-grip gourd needs 5 minutes

Parameter Of Wood Beads Making Lathe

|

Performance Parameters

|

||

|

processing diameter

|

8-150mm

|

|

|

Processing max length

|

10-1000mm

|

|

|

Auto drilling

|

With(can change into turning thimble)

|

|

|

Processing precision

|

0.01MM

|

|

|

Operating system

|

Special wood beads system we studyed

|

|

|

Drawing software

|

CAD

|

|

|

Drawing format

|

*.dxf

|

|

|

Transmission way

|

TBI ballscrew

|

|

|

guider

|

Taiwan Hiwin/PMI square orbit

|

|

|

Driving system

|

Step motor and driver

|

|

|

Whole machine power

|

1.5KW

|

|

|

Motor power

|

750w

|

|

|

Voltage

|

220V single phase, 50HZ

|

|

|

Packing size

|

1500*800*700mm

|

|

Detailed Images Of Wood Beads Making Lathe

Sample Of Wood Beads Making Lathe

2.what shape do you need

it’s better show me your sample pictures , i will introduce best one for you

3.min order 1 set , agent for 5 sets

You Qcan tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q2: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by “Team viewer”online, with telephone or Skype explain.

Q3: Can you customize the machine for me?

Yes, we provide customized solution, but considering the cost, we will recommend the

standard configuration to you first.

Q4: What is the guarantee? In case the machine break down?

The machine has 1 year guarantee, fail parts will be replaced for free if the machine under

” normal operation”.

Q5: How about the documents after shipment?

We will send all the documents by air after shipment. Including packing list, commercial

invoice, B/L, and other certificates required by clients.

Q6: Delivery time?

For standard machine, it would be 7-10 working days; for non-standard machine, it would be 20 – 30 working days.

Q7: How is the payment?

Normally we accept T/T or L/C, if you like other terms, tell us in advance.

Q8: Do you arrange the shipment for me?

For FOB or CIF price, we will arrange shipment for you, for EXW price, you should arrange

the shipment by yourself.

Q9: How is the packing?

Step1: water proof wrapping film with foam protection in each corner.

Step2: Solid seaworthy wood box package with steel belt.

Step3: Save space as much as possible for container loading.

– All machines are debugged before shipment.

– Lifetime technical support and service.

– 24 hours on line or phone or by email technical support.

– We offer detailed machine manual, software manual, controller manual.

– Our factory make a vivid traing CD.

– Maintenance free of charge during lifespan.

– Free training course at our plant.

– Welcome to visit our factory, learn machine face to face.

● the foundation construction unit shall provide the quality certificate of the equipment foundation (such as ratio, maintenance, strength).

● if there is doubt about the strength of the equipment foundation, the strength of the foundation can be re-measured by springback instrument or steel ball impact method.

● check the appearance of the foundation

● check the position and geometry of the foundation

Preloading test of heavy equipment base is to prevent the heavy equipment due to the uneven subsidence of the foundation after installation equipment installation is unqualified preloaded pressure not less than equipment running at full capacity (the sum of the force on the basis of equipment), the heavy equipment can be installed level requirement is not high, only when the equipment test run on the basis of settlement observation.

We have our own patented technology and research team,can provide you with professional and timely technical support.We are trustworthy.

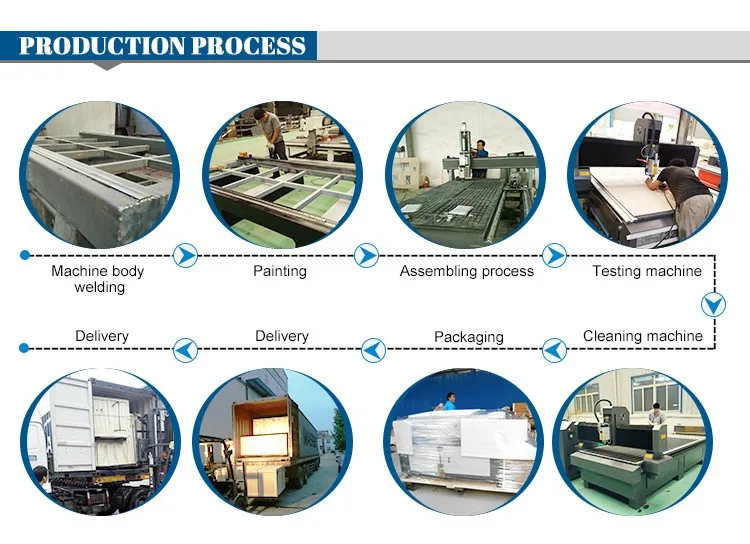

2.Painting

3.Assembling process

4.Testing machine

5.Cleaning machine

6.packing

7.delivery

8.transport

You can tell us your working material, detail work by picture or vedio so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.

Q2:What can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q3:This is the first time I use this kind of machine, is it easy to operate?

We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by “Teamviewer” online help software.Or we can talk by phone, email or other contact ways.

Q4:How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized machines according to client s specific requirements, it would be 15 to 30 days.

Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents

Reviews

There are no reviews yet.