Industrial Ultra-low Nitrogen Burner

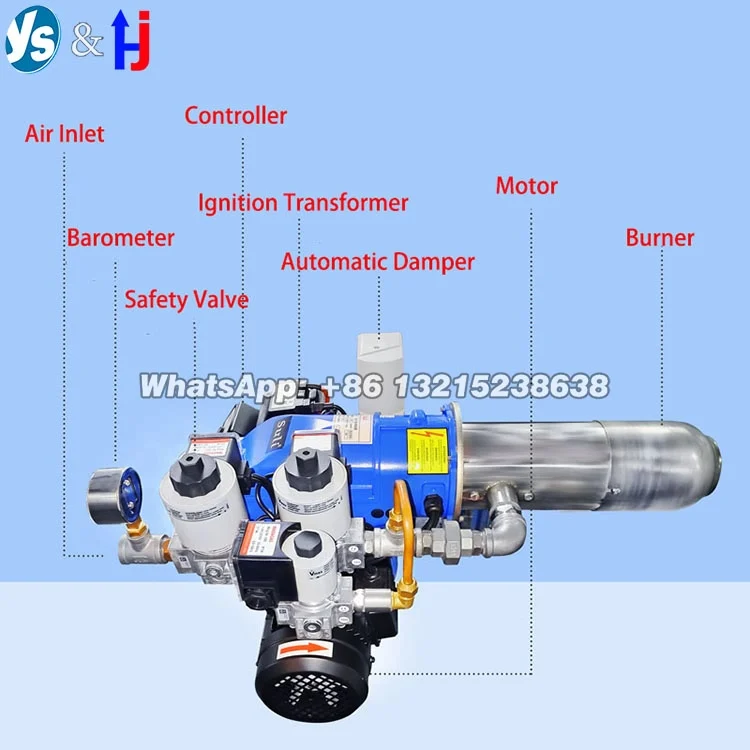

Installation Process:

1. Install the mounting flange asbestos gasket on the combustion tube, extend the combustion tube into the furnace, and align the screw holes to fix the mounting flange on the furnace body. After confirming the position of the extension into the furnace, lock the screws everywhere. Make sure that the burner is installed firmly. Note that the burner should be installed horizontally or vertically, not inclined.

2. After the burner body is installed, connect the fuel oil inlet and return pipes to the oil inlet and return ports of the oil pump according to the design. It should be noted that a filter should be installed on the oil inlet pipe and the filter should be cleaned regularly. After the connection is completed, check the tightness of the pipeline.

Daily maintenance of the burner:

1. Daily maintenance and maintenance

(1) Always keep the surfaces clean.

(2) When the equipment is stopped, each rotation of the quick opening blind plate (flange cover) should be lubricated in time according to the regulations. The screw at the opening and closing parts should be coated with lubricating grease. Other parts should also be coated with lubricating grease. The lubricating grease part can be filled with 10# or 20# oil.

2. Maintenance and maintenance during operation

(1) It is recommended that the operator be responsible for the usual maintenance of the equipment.

(2) Always keep the equipment surface clean.

(3) Monitor the reading of the differential pressure gauge at any time. When the pressure difference reaches 0.O2Mpa, the filter element should be flushed.

3. Inspection cycle

(1) The periodic inspection of this equipment must be carried out in strict accordance with the relevant regulations in Chapter 6 of the “Capacity Regulations”.

(2) Carry out a comprehensive inspection of the equipment at least once a year, and measure the wall thickness of the equipment, and conduct a non-destructive test on the pressure welds of the equipment every two years. All inspection and test results should be recorded in the technical file of the equipment.

(3) When there is pressure inside the equipment, no maintenance is allowed. For maintenance under special circumstances, it must be carried out in strict compliance with the provisions of Article 122 of the “Rong”.

4. Maintenance when parking

(1) When the equipment is parked, the liquid in the equipment should be drained.

(2) Close all valves.

(3) Thoroughly clean the surface of the equipment.

(4) All rotating parts are coated with anti-grease.

(5) Cover all the devices with canvas to prevent dust and dirt from depositing on the surface of the equipment.

1. How fast can I get the quotation?

We usually quote immediately (whthin 30 minutes) after we get your inquiry.If you are very urgent to get the price, please call us on Alibaba / WhatsApp / Skype / Gmail.

2. How can I get a sample to check your quality?

(1). Contact us, and we will negotiate the best price possible for you.

(2). Free Sample: Sample cost can be refundable if your following order quantity is large enough.

3. How to pay?

1). To pay by Alibaba Trade Assurance Order, which can be drafted by us. All order details and payment methods are included. Please send us your consignee information including name, detailed address, cell phone number and zip code after confirmation of product specification, order quantity and price with us. You will receive Trade Assurance Order by mail when it’s drafted. Please check all the order details and make the payment.

Secure online payment options include e-Checking, credit card and T/T.

2). To pay offline, you can pay by T/T, Western Union, PayPal, Alipay and WeChat Pay. We will send you our account information.

3). We will handled your order within 24 hours upon receiving cleared payment.

4. How fast can I get my package?

(1). DHL: Southeast Asia 3-4 days / others 3-5 days.

(2). FedEx: Southeast Asia 3 days / others 4-6 days.

(3). UPS: Southeast Asia 3-4 days / others 4-6 days.

(4). TNT: Southeast Asia 3-4 days / others 4-6 days.

|

Reviews

There are no reviews yet.