wood beads cnc lathe machine with drilling

1.Brief Introduction

Processing Size

max diameter 8cm, max length 30cm

Make Drill Way:

with automatic drill, computer controlled automatic concentric perforated

Power:

220V

whole machine power: 1000w

spindle motor power: 750w

Operate Way:

Direct input required in the software

Bead diameter can be simple parameters; pagoda gourd, direct

Select the shape, size. No programming, easy to use.

You can also design your own style, drawing of contour line, put into

BMP, JPG image can be processed.

Precision:

imported square orbit and ballscrew transmission

long lifespan, high precision

processing precision: 0.01mm

Cutter lifespan:

Adopt super hard alloy cnc cutter(special for stainless steel),no wear for turning and milling red wood.processing 3000 pieces Lobular red sandalwood whose diameter 2cm, no need chang cutter.

Very long service life, is the standard

Piece. If there is damage to the direct replacement, without understanding thesharpening technique.

Processing speed:

In the processing of 2 size beads shall prevail, lobular Rosewood automatic

Hole, turning every 38 seconds, 30 seconds without holes.

Phoebe play hole turning, every 25 seconds, not punching every 19 seconds;

The processing of 5 cm diameter handball, 2.5 minutes one piece.

Processing handgrip gourd, diameter 5 cm, 11 cm long with 5 minutes.

2.Application

Bead, barrel, all kinds of buddha head pagoda, gourd pendant, hoist pieces, wood rhinoceroshorn

cup, bowl, whip,cigarette holder, eggs,ashtray, scroll painting head.

3.Advantage Of CNC Wood Beads Making Lathe

- It is computer nemerical controled

- It is with 300 kinds drawing gallery except for round beads

- Eeasy controled special wood beads machine control system is studied by us

- Best hard alloy wood lathe cutter in China market, can match with you soft wood cutter and hard wood cutter

- Can designed by your requirement

- Imported square orbit and ballscrew transmission

- Long lifespan, high precision

- Processing precision: 0.01mm

4.Technical Parameters

|

Model |

TJ 3080 |

|

Max. swing over bed |

80mm |

|

Distance between centers |

300mm |

|

Spindle bore |

21mm |

|

Taper of Spindle bore |

MT3 |

|

Range of Spindle speeds |

50-2500rpm |

|

Taper of tailstock quill |

MT2 |

|

Metric threads can be cut |

0.5-3mm |

|

Inch threads can be cut |

10-44TPI |

|

Max travel of cross slide |

75mm |

|

Bed of width |

100mm |

|

Travel of Tailstock sleeve |

60mm |

|

Motor power |

650W |

|

Driver |

Stepper motor |

|

Transmission |

Square orbit ballscrew |

|

GW/NW |

75/60KG |

|

Package size( L*W*H ) |

780*480*420mm |

5.Cutter lifespan

Adopt super hard alloy cnc cutter(special for stainless steel),no wear for turning

and milling red wood.

processing 3000 pieces Lobular red sandalwood whose diameter 2cm, no need chang cutter.

Very long service life, is the standard Piece.

If there is damage to the direct replacement, without understanding thesharpening technique.

6.Detailed Images

7.Sample

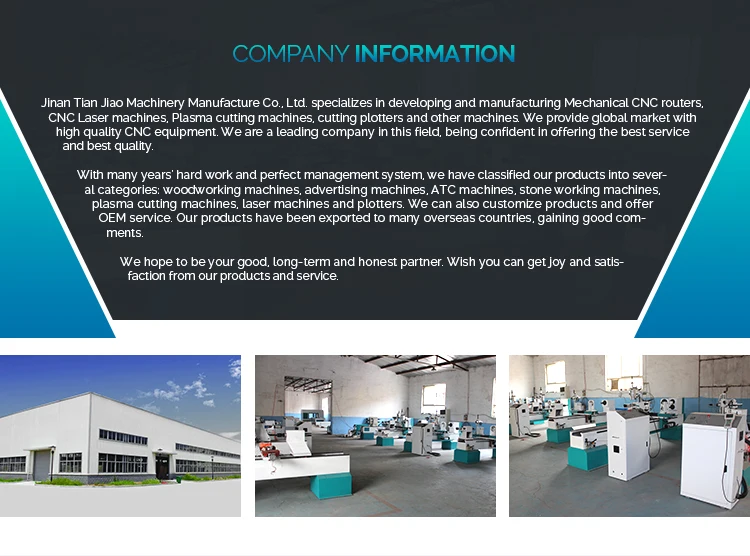

Why choose Tianjiao product?

1.Tianjiao product is widely used in almost all the materials which you can think of.

2.Tianjiao Company is specialized in cnc router and cnc lathe machine manufacturing and selling.

There is no middle man and no agent, so the price is moderate.

3.Tianjiao machine with high precision and high reputation is the most reliable goods you can choose

4.Tianjiao Company has all kinds machines in store, the delivery time is much shorter than other

companies.

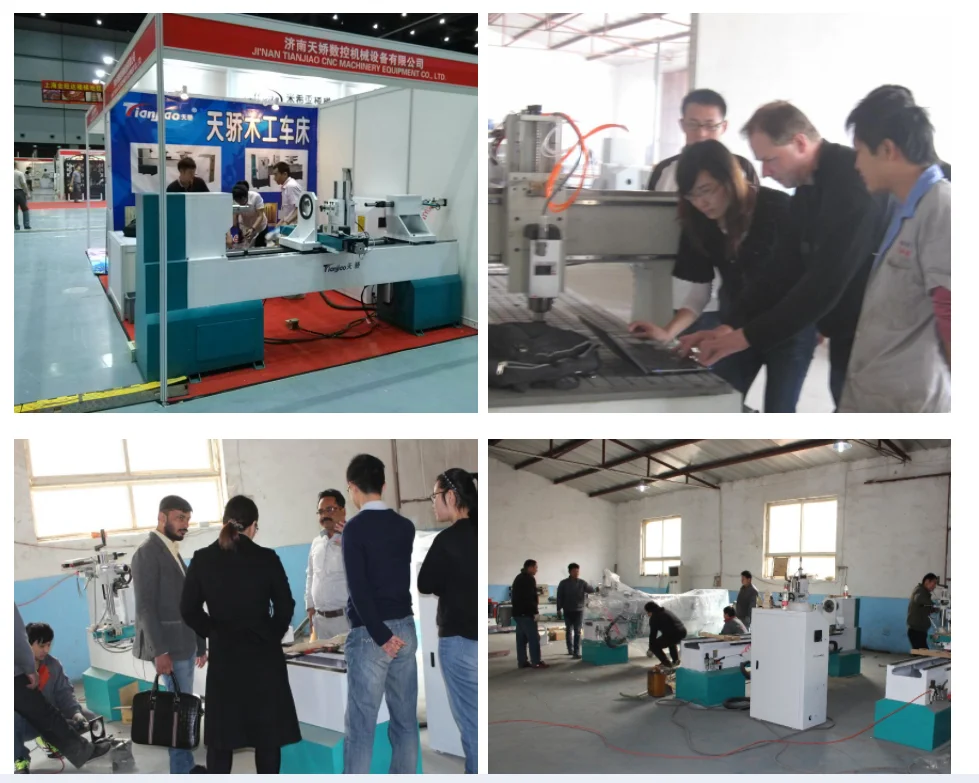

Our customers

Iraq customers

You can tell us the working piece material, size, and the request of machine function. We can

recommend the most suitable machine according to our experience.

Q2: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can

also help you by “Team viewer”online, with telephone or Skype explain.

Q3: Can you customize the machine for me?

Yes, we provide customized solution, but considering the cost, we will recommend the

standard configuration to you first.

Q4: What is the guarantee? In case the machine break down?

The machine has 1 year guarantee, fail parts will be replaced for free if the machine under

“ normal operation”.

Q5: How about the documents after shipment?

We will send all the documents by air after shipment. Including packing list, commercial

invoice, B/L, and other certificates required by clients.

Q6: Delivery time?

For standard machine, it would be 7-10 working days; for non-standard machine, it would be

20 – 30 working days.

Q7: How is the payment?

Normally we accept T/T or L/C, if you like other terms, tell us in advance.

Reviews

There are no reviews yet.