Water Filling Machine * water bottling machine * mineral water filling machine * pure water filling machine

* pure water bottling machine * water bottling plant * water filling equipment * water filling machine supplier

* mineral water pet bottle machine * water filling machine manufacturer * mineral water bottling equipment

* bottled water machine * mineral water plant * water production machine * bottled water making machine

* pure water bottling machine * water bottling plant * water filling equipment * water filling machine supplier

* mineral water pet bottle machine * water filling machine manufacturer * mineral water bottling equipment

* bottled water machine * mineral water plant * water production machine * bottled water making machine

There’s many water filling machine for sale, but need confirm first for bottle sizes, such as 200-2000ml, 5-10L, 20L bottle,

confirm for market needs first, then you can start designing automatic water filling machine complete line. More automatic degree will save more labor and getting better working efficiency. water filling machine for sale of our stock line of small and big bottles will allow you to get a quicker start.

Working principle:

bottle into bottle support ring, and bottle neck support catch the bottle neck, than main shaft turned 180degree under gear wheel. Let bottle’s mouth face to land, jetting water into bottle, after a few seconds, the main shaft will be back, than finishing the washing.

2.The machine is composed water tank, float ball, shaft, filling valve, Pneumatic component, electric machine. Washing finished bottle is conveyed into filling position , cylinder push and hold the plate which can hitch bottles , the mouth of bottle can open the valve, finishing filling, plate which can hitching bottle will running down, the valve will closed automatically, the time lasting of filling can be adjusted.

3. The working is intermission when running with automatically capping. The capper will be screw type with 3 start neck finish.

Machine structure

– washing, filling and capping part in one unit;

– one driving system makes the speed more stable

– need one person to operate the machine

– no noisy while running,more compact

– different bottles can be applied in same machine (the bottle neck should be the same)

Washing part/ Rising heads

– there is nylon grip to protect bottle mouth

Filling part/ Filling heads

– the valves are stainless steel 304

– no bottle no filling

– filling level can be adjusted

Capping part/ Capping head

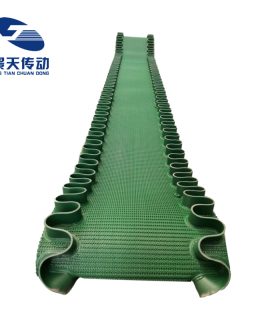

Italy technology capping more precision,Belt type cap uploader with new tehnolgy avoid cap blocking.

Control system

– Touch screen

Bottle design service

Bottle label service

Water Bottling Machine

|

500ml water bottle fillling machine

|

||||||||||||||

|

Model

|

40-40-12

|

32-32-10

|

24-24-8

|

24-24-8

|

18-18-6

|

12-12-4

|

||||||||

|

Capacity (500ml)

|

20000 BPH

|

14000-16000 BPH

|

12000 BPH

|

10000 BPH

|

8000 BPH

|

6000 BPH

|

4000 BPH

|

|||||||

|

Bottle Size

|

150- 2000ml

|

|||||||||||||

|

Water Pressure

|

0.18-0.25Mpa

|

|||||||||||||

|

Water Consumption

|

1500kg/h

|

1000kg/h

|

||||||||||||

|

Washing Valves

|

40

|

32

|

24

|

18

|

12

|

|||||||||

|

Filling valves

|

40

|

32

|

24

|

18

|

12

|

|||||||||

|

Capping Heads

|

12

|

10

|

8

|

6

|

4

|

|||||||||

|

Filling Precision

|

<+5MM

|

|||||||||||||

|

Air Pressure

|

0.5Mpa

|

|||||||||||||

|

Air Consumption

|

0.3m3/min

|

|||||||||||||

|

Power

|

7.5kw

|

6.0kw

|

5.0kw

|

2.5kw

|

||||||||||

|

Weight

|

5000kg

|

4000kg

|

3500kg

|

|||||||||||

|

Size(I*w*H m)

|

3.2*2.1*2.1

|

3*2.1*2.1

|

2.7*2.1*2.1

|

2.35*2.1*2.1

|

||||||||||

|

5L water bottle fillling machine

|

||||||

|

Model

|

24-24-8

|

12-12-5

|

8-8-3

|

|||

|

Capacity (5L B/H)

|

4000 BPH

|

2000 BPH

|

||||

|

Bottle Size

|

5-10L

|

150- 2000ml

|

||||

|

Water Pressure

|

0.18-0.25Mpa

|

|||||

|

Water Consumption

|

1500kg/h

|

500kg/h

|

||||

|

Washing Valves

|

24

|

12

|

8

|

|||

|

Filling valves

|

24

|

12

|

8

|

|||

|

Capping Heads

|

8

|

5

|

3

|

|||

|

Filling Precision

|

<+5MM

|

|||||

|

Air Pressure

|

0.5Mpa

|

|||||

|

Air Consumption

|

0.3m3/min

|

|||||

|

Power

|

3.5kw

|

2.2kw

|

||||

|

Weight

|

4000kg

|

2000kg

|

||||

|

Dimension (I*w*H)

|

3*1.9*2.1m

|

2.3*1.9*2.1m

|

||||

|

20L bottle water filling machine

|

||||||||||

|

Model

|

LBJ-200

|

LBJ-300

|

LBJ-450

|

LBJ-600

|

LBJ-900

|

|||||

|

Washing station

|

1 row

|

2 rows

|

3 rows

|

4rows

|

6rows

|

|||||

|

Filling nozzles

|

1

|

2

|

3

|

4

|

6

|

|||||

|

Bottle type

|

5 gallon Diameter:270mm; Height:490mm

|

|||||||||

|

Production capacity

|

100-200BPH

|

250-300BPH

|

400-450BPH

|

550-600BPH

|

850-900BPH

|

|||||

|

Gas consumption

|

0.37m3/min

|

0.6 m3/min

|

1.2 m3/min

|

2.2 m3/min

|

||||||

|

Pressure

|

0.4-0.6Mpa

|

0.6Mpa

|

||||||||

|

Power

|

1.75kw

|

3.22kw

|

4.8kw

|

1.2kw

|

2.2kw

|

|||||

|

Voltage

|

380V 3phase 50HZ / CUSTOMIZE

|

|||||||||

|

Machine size

|

3190*650*1550mm

|

3100*900*1650mm

|

3550*1100*1800mm

|

3800*1100*1800mm

|

3800*2200*1800

|

|||||

|

Weight

|

800kg

|

1350kg

|

1860kg

|

2300kg

|

3300kg

|

|||||

|

Features

|

Our 20L bottle water filling machine is suitable for 20L bottle and 5 gallon and 3 gallon barrel. we can provide speed from 100-2500BPH. complete line include: bottle loader–bottle de-capper–bottle brusher–bottle high pressure rinser–bottle multi-washing machine–bottle filling capping machine–bottle bagging machine–bottle palletizer.

|

|||||||||

|

Advantages

|

Does not damage the barrel, no second pollution, the equipment in the same in a leading level, is the large and medium-sized enterprise ideal equipment for barreled water. capacity: 600 barrels / hour to 2500 barrels / hour

|

|||||||||

|

Applications

|

20L bottle water filling machine is mainly applied for the filling of beverage. Integrating with washing, filling and sealing, it realizes full automation in the whole process, suitable for polyester bottle and plastic bottle filling of mineral water and purified water.

|

|||||||||

|

25000BPH High Speed PET Bottle Water Filling Bottling Machine

|

||||||||

|

Model

|

60-40-15

|

18-18-6

|

24-24-8

|

32-32-10

|

||||

|

Capacity

|

25000BPH

|

5000-6000BPH

|

8000-10000BPH

|

10000-14000BPH

|

||||

|

Applicable bottle

|

Plastic bottle 500ml-1.5L

Plastic screw cap

|

|||||||

|

Applicable filling content

|

Mineral water, wine, non-carbonated water

|

|||||||

|

Washing station

|

60

|

18

|

24

|

32

|

||||

|

Filling nozzle

|

40

|

18

|

24

|

32

|

||||

|

Capping head

|

15

|

6

|

8

|

10

|

||||

|

Main motor power

|

15kw

|

2.5kw

|

||||||

|

Water pump power

|

0.37kw

|

|||||||

|

Dimension

|

4350*2850*2450mm

|

2700*2100*2450mm

|

2800*2400*2450mm

|

3200*2800*2450mm

|

||||

|

Weight

|

5500kg

|

4500kg

|

5500kg

|

6800kg

|

||||

Inroduction of Water Production Line

flavored water, alcoholic beverage and other non-gas Liquid. This Machine can be applied to all kinds of plastic products such as PET, PE. Bottles size varies from 250ml-2500ml meanwhile few changeover is needed. This series of filling machine capacity varies from 1000BPH to 32000BPH.

Our water filling machine is designed for the bottle water factory. It features low water and low electricity consumption, small space occupation as well as easy operation. At the same time It improves the sanitary conditions and simplifies the maintenance compared with the last generation water filling machine. it can perfectly complete the function of automatic washing, filling and capping, which has been aproved by our clients as technical matured and quality product.

Installation of equipment or bottling line at the customer’s plant Coordinate schedule with mechanics to perform changeovers and preventive maintenance activities Perform mechanical adjustments (if needed) on equipment and packaging line to optimize equipment’s performance Resolve equipment issues Document all work activities according to Proper Documentation Practices Provide on-site training on all assigned procedures An LIBAIJIA Packaging Technician will be in-charge of the equipment setup and adjustment in your plant. All of the activities will be focused on optimizing the equipment to maximize production output. LIBAIJIA also ensures that the technician will execute routine packaging operations to fully meet production demands.

Ghana water filling 3 to 5 gallon water filling machine filling machine bottle water

Kenya small bottle water filling machine water filling machine cup

bottle filling machine

water filling machine water bottle filling machine

Main Features Of Small Bottle Drinking Water Filling Machine

2, This machine uses new generation stainless steel spring washing clips and the clips do not contact the upside of bottle screw avoiding the second pollution. It can both clear the inside and the outside of the bottle.

3, The advanced normal pressure filling principle was applied. Filling is quick, and stable. Not contacting with the liquid avoids second pollution and oxidation.

4, This machine applies magnetic force screw type sealing, realizing auto grasping cap, sealing. The sealing cap force can be adjusted.

5, Independent electricity box makes sure every electrical appliance works normally.

Reviews

There are no reviews yet.