Product Description

Support the proofing of welding products.Customized service: We can design and develop welding machines according to your requirements. We have many welding design cases, including automatic welding production lines. We are an efficient and capable OEM supplier.

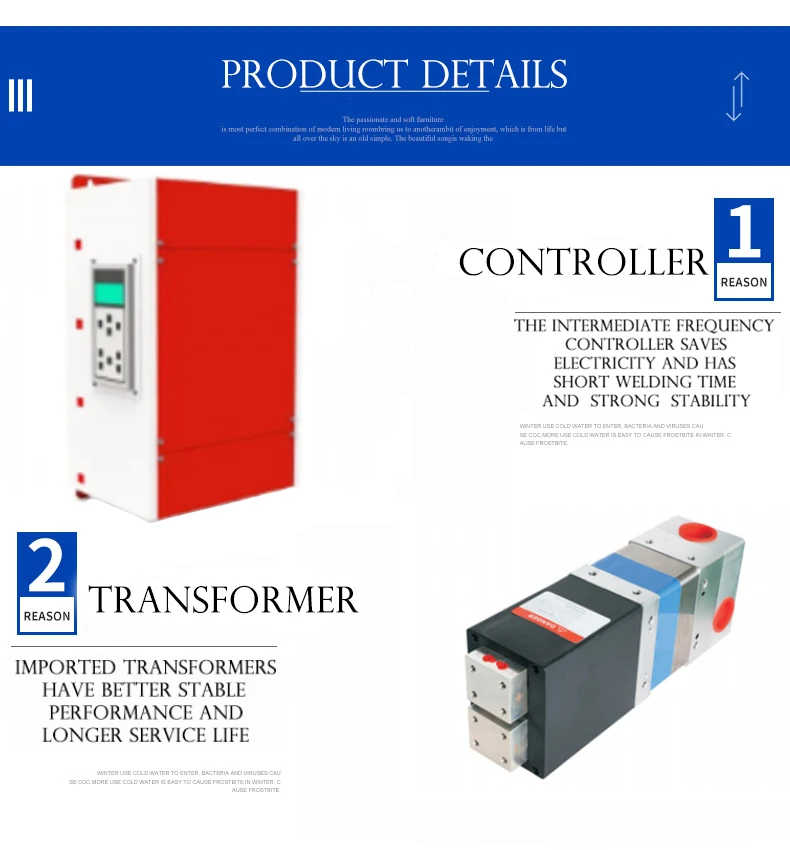

Feature:

* No Limitation for resistance current, reduce pyrotoxin.

*No oxidation at spot joint, polishing can be eliminated.

*A builtin voltage regulator ensures constant output voltage.

*Digital controller, high accuracy.

*other precision components and parts are sourced from worlds’ best manufacturers and renowned sources.

*The welder is easy to operation and free of complicate educational procedure, can be very easy to adopt and operated.

*Primary welding material: stainless, brass, copper alloy, and aluminium alloy.

*Suitable for electric appliance, watch chain, jewelry, stainless stableware, and hardware manufacturers.

*No oxidation at spot joint, polishing can be eliminated.

*A builtin voltage regulator ensures constant output voltage.

*Digital controller, high accuracy.

*other precision components and parts are sourced from worlds’ best manufacturers and renowned sources.

*The welder is easy to operation and free of complicate educational procedure, can be very easy to adopt and operated.

*Primary welding material: stainless, brass, copper alloy, and aluminium alloy.

*Suitable for electric appliance, watch chain, jewelry, stainless stableware, and hardware manufacturers.

Specification

|

Item

Model |

Power input

|

Interior input power

|

Capacitance

|

Energy storage

|

Arm length

|

Electrode stroke

|

Electrode pressure

|

Weight

|

|

V

|

KVA

|

Μf

|

J

|

mm

|

mm

|

N

|

Kg

|

|

|

DR-500

|

380

|

2

|

5000

|

500

|

120

|

50

|

1200

|

200

|

|

DR-1500

|

380

|

3

|

15000

|

1500

|

380

|

80

|

3000

|

450

|

|

DR-3000

|

380

|

5

|

30000

|

3000

|

380

|

80

|

4700

|

800

|

|

DR-5000

|

380

|

7

|

50000

|

5000

|

380

|

80

|

7300

|

800

|

|

DR-8000

|

380

|

10

|

80000

|

8000

|

380

|

80

|

7300

|

1000

|

|

DR-10000

|

380

|

12

|

100000

|

10000

|

450

|

100

|

12000

|

1200

|

Company Profile

Established in 1995, TRINTFAR is a high-tech enterprise of automatic welding equipment integrating scientific research, development, manufacturing and sales.

As a national high-tech enterprise, after more than 20 years of unremitting efforts, TRINTFAR has many cutting-edge welding technology products, including medium frequency, high frequency inverter resistance welding machine, numerical control resistance welding, laser welding equipment, automobile welding production line, welding robot integrated system, high speed steel drum seam welding machine, etc. It is not only used in major automobile manufacturing and parts manufacturing enterprises, but also in aerospace, home appliance manufacturing, high-speed rail, low-voltage electrical appliances and other industries. The innovative team, excellent product design, advanced technology and reliable quality have made the Trintfar brand a reputation as a “reliable partner” in the welding equipment market at home and abroad.

At present, Trintfar has a large number of high-quality talents who are dedicated, innovative, and united. All staffs adhere to the “sincere, innovative” business philosophy, has been committed to providing customers with efficient welding automation solutions. From consulting to welding equipment operation and maintenance, our service has been accompanied by our customers.

With high-tech and high-quality services, we will continue to work hard and innovate. We sincerely and enthusiastically expect to share with our customers the high efficiency, high quality and work pleasure brought by our combination of advanced technology and lean production.

As a national high-tech enterprise, after more than 20 years of unremitting efforts, TRINTFAR has many cutting-edge welding technology products, including medium frequency, high frequency inverter resistance welding machine, numerical control resistance welding, laser welding equipment, automobile welding production line, welding robot integrated system, high speed steel drum seam welding machine, etc. It is not only used in major automobile manufacturing and parts manufacturing enterprises, but also in aerospace, home appliance manufacturing, high-speed rail, low-voltage electrical appliances and other industries. The innovative team, excellent product design, advanced technology and reliable quality have made the Trintfar brand a reputation as a “reliable partner” in the welding equipment market at home and abroad.

At present, Trintfar has a large number of high-quality talents who are dedicated, innovative, and united. All staffs adhere to the “sincere, innovative” business philosophy, has been committed to providing customers with efficient welding automation solutions. From consulting to welding equipment operation and maintenance, our service has been accompanied by our customers.

With high-tech and high-quality services, we will continue to work hard and innovate. We sincerely and enthusiastically expect to share with our customers the high efficiency, high quality and work pleasure brought by our combination of advanced technology and lean production.

Reviews

There are no reviews yet.