TPR-1325 modle 3d cnc wood carving machine 1325 cnc router machine

|

Machine application |

|

1. Furniture industry:

2. Advertising industry:

3. Handicraft industry: 4. Decoration industry: MDF, ceiling, laminate flooring, gypsum board, blockboard, MDF, multilayer board, integrated board, mineral wool board, aluminum gusset, ceramic tile, stone, glass ceramics, etc.

5. Coffin industry: urns, coffins, etc. |

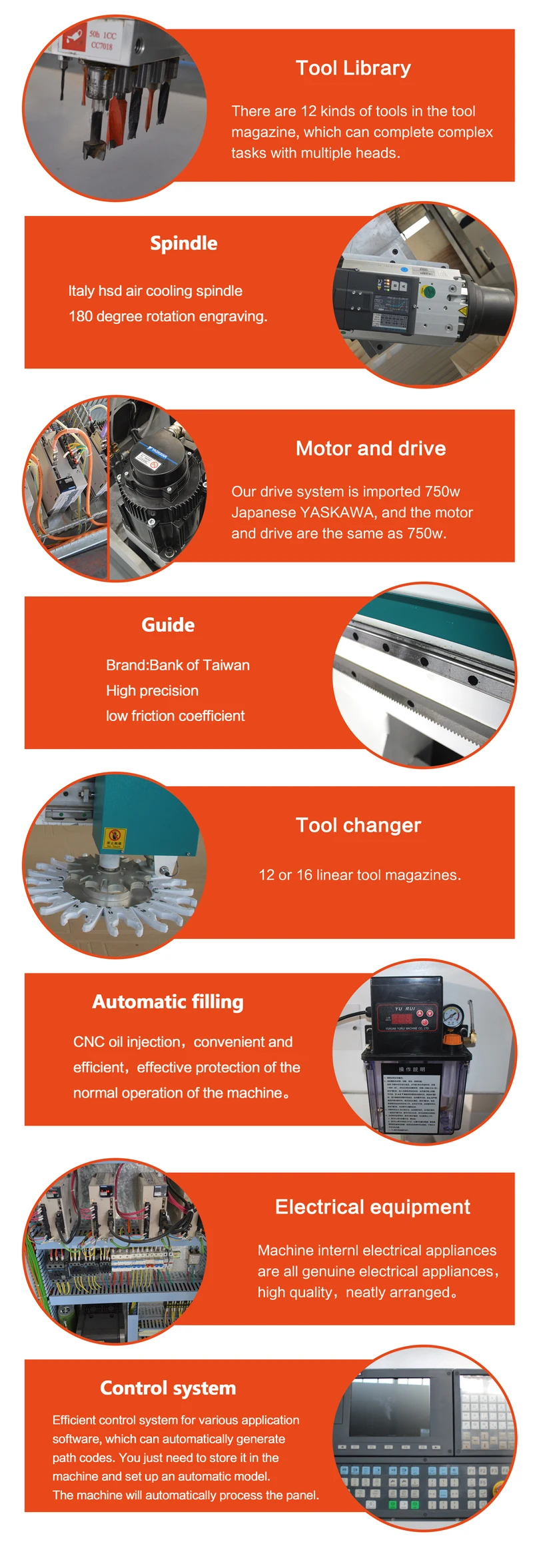

| Machine details |

| Machine features |

|

1. The software equipped with the machine is compatible with various CAD/CAM design and production software such as TYPE3, Artcam, Jingdiao JD, Wentai Carving, UG, MasterCAM, PowerMill, etc.

2. Advanced numerical control processing system, powerful function, humanized operation, data can be received through U disk or network.

3. Servo drive and motor, with high power, fast processing speed, stable operation and extremely low noise.

4. High-power spindle, constant power, low noise, super cutting power, greatly improving work efficiency.

5. Imported high-precision linear track, stable operation, high precision, stable support, and extend the service life of the machine.

6. The Z axis adopts imported industrial-grade ball screw, which has accurate positioning and perfect processing effect.

7. All three axes use high subdivision stepper driver, Y axis is equipped with dual motor drive, and is equipped with large torque high speed stepper motor, one knife can cut 3cm wood.

8. Equipped with an independent control cabinet, which is convenient for machine maintenance. The electrical and motor control protection level has reached the EU IP54 or above, and the industrial-grade wiring standard has excellent anti-interference ability.

9. Energy-saving system-the electric spindle is controlled by high-performance vector frequency conversion technology, which has the advantages of fast response and low power consumption. |

| Machine parameters |

|

Product name |

3d Router Wood Carving machine |

| Model | TPR-1325 |

| XY working area | 1300*2500 mm |

| Z working area | 200mm more |

| Control system | Taiwan LNC Control System |

| Software | Ucancam / ArtCam/TYPE3 |

| Working table | Vacuum + T-slot |

| Max. speed | 60 m/min |

| Max. working speed | 30 m/min |

| Power | AC 380/50HZ/60HZ |

| Spindle | 9 KW air cooling spindle |

| Speed of spindle | 0-18000 rpm/min |

| Drive motor | Steper Motors |

| Inverter | Fuling Inverter |

| Machine description |

| It is composed of computer, engraving machine controller and engraving machine host. Working principle: The design and layout are carried out through the special engraving software configured in the computer, and the design and layout information is automatically transmitted to the engraving machine controller by the computer, and then the controller converts the information into a stepping motor or The signal (pulse train) with power of the servo motor controls the host of the engraving machine to generate X, Y, Z three-axis engraving tool path base diameter. At the same time, the high-speed rotating engraving head on the engraving machine is configured according to the processing material to cut the processing material fixed on the worktable of the host, and can engrave various flat or three-dimensional relief graphics and texts designed in the computer. Realize the automation of carving. |

| Machine shipping |

| Our sevices |

|

1. Pre-sale: We provide free technical consultation, please tell us your needs, we will provide you with the most suitable machine and the best price.

2. During the production process: We will send photos and take machine videos during the production process so that customers can learn more details about the manufacturing machine. And give them advice.

3. Before delivery: We will confirm the order specifications, and package and ship according to customer requirements. And test and adjust the machine until it reaches the best performance.

4. After delivery: We will provide you with tracking information of ships at sea, so that customers know when they will arrive at your port and are fully prepared.

5. After arrival: We will confirm with you whether the machine is in good condition, and check whether any spare parts are damaged during the shipping, and then solve the insurance problem for you.

6. About training: There are some manuals and videos about how to install and use the machine. If you have any questions, you can contact me at any time, and then I will arrange our professional and technical personnel through video, picture, phone or email or overseas service.

7. About the warranty: We provide a 2years warranty for the whole machine. |

| FAQ |

|

Q1: Are you a factory or a trading company? Q2: This is my first time using this kind of machine. Is it easy to operate? Q3: How long is the delivery time? What is your fast delivery time? Q4: How should I pay? What is the parade purchased this time? Q5: What should I do if there is a malfunction after I receive the machine? |

| Company information |

| Shenzhen Tip-Top Manufacture & Trading Co., Ltd is a branch company with engineers and research and development for 16 years. It is a professional manufacturer engaged in the research, development, production, and service of fiber laser marking machine. Fiber cutting machine , fiber marking machine, CNC router, laser engraving machine, laser welding machine, and plasma cutting machine. We have CE/ ISO certificates, conform to export qualifications, and have many agents abroad. Welcome to visit our company. |

Reviews

There are no reviews yet.