geomembrane welding machine for earthen pond in Aquaculture farm SWT-NS900

hot wedge welder welding HDPE Dam Liners for Water Containment Project SWT-NS900

HDPE liners welding machine for Mining heap leach,slag tailing ponds SWT-NS900

hot wedge welder welding HDPE Dam Liners for Water Containment Project SWT-NS900

HDPE liners welding machine for Mining heap leach,slag tailing ponds SWT-NS900

Instruction

SWT-NS series geo-membrane welding machine is our new developed products, which can weld geo-membrane of various thickness and are applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and so on.

Hot Wedge Welder is small, light,high welding efficient.

This hot wedge welder is available for welding HDPE, LDPE ,EVA ,PVC, ECB, PP and other hot melt materials.

It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

Features

1.Contorl System:Advanced intelligent digital control system which temperature and speed readed on LCD screen.2.Pressure

Adjustment System:advanced"T"jib design and pressure regulation structure.

3.Pressure Roller:special stainless steel pressure roller with strong pressure force.

4.Hot Air Heating System:advanced hot air heating system perfects the welding quality even if corrosive material and bad working

environments.

Adjustment System:advanced"T"jib design and pressure regulation structure.

3.Pressure Roller:special stainless steel pressure roller with strong pressure force.

4.Hot Air Heating System:advanced hot air heating system perfects the welding quality even if corrosive material and bad working

environments.

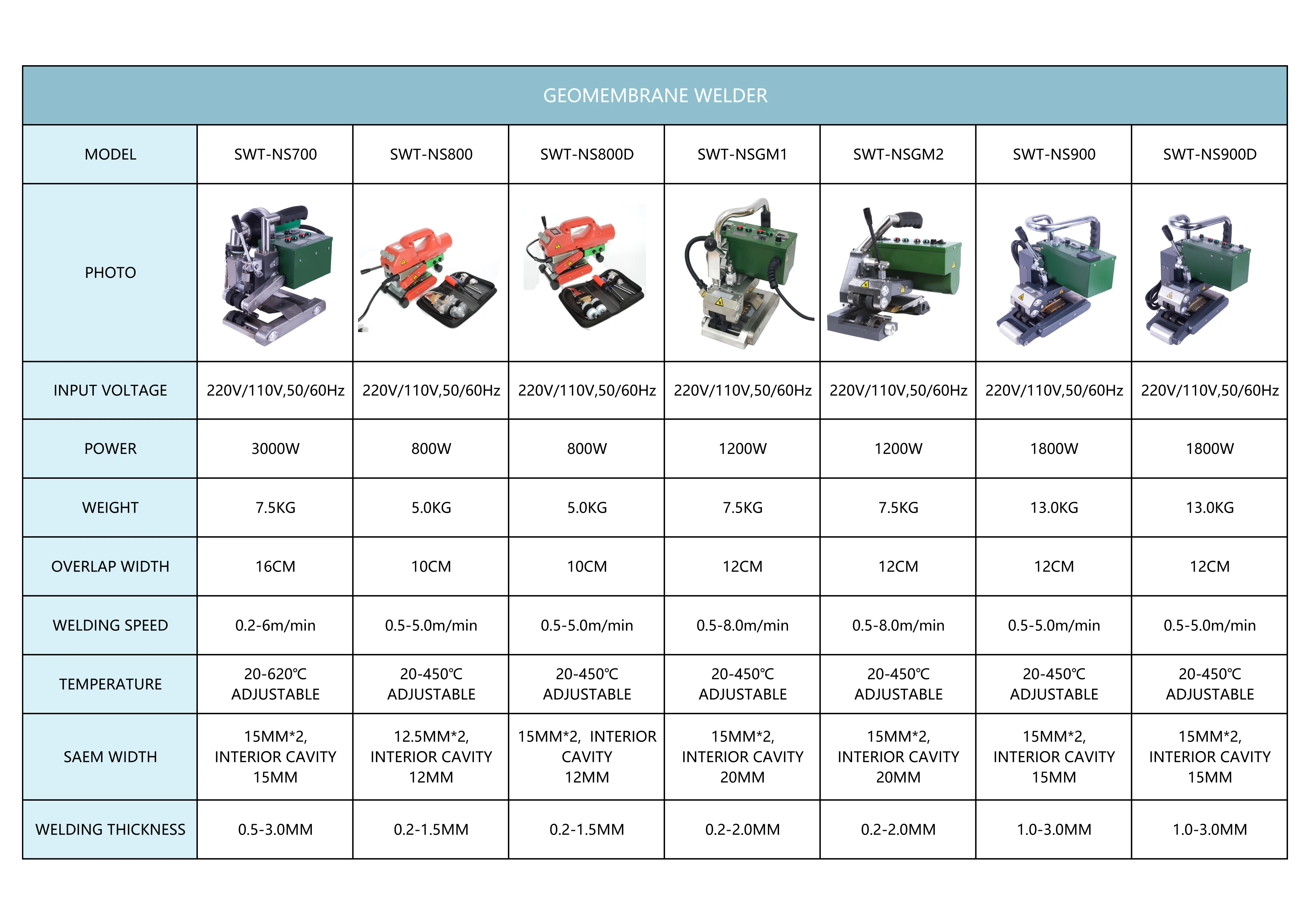

Parameters

|

MODEL

|

SWT-NS900

|

|

INPUT VOLTAGE

|

220V/110V,50/60HZ

|

|

POWER

|

1800W

|

|

Welding width

|

15 mm *2, interior cavity 15mm

|

|

OVERLAP WIDTH

|

120MM

|

|

WELDING SPEED

|

0.5-5m/min

|

|

Thickness of material

|

1.0-3.0 mm

|

|

Seam Strength

|

≥85% base material ( tensile resistant in shear direction)

|

We always provide high quality products and workable price for every clients and have won the trust and approval.

Machine Quality Guarantee: 24 months.–If any parts broken or does not work under normal operating, we provide them for free.

Machine Quality Guarantee: 24 months.–If any parts broken or does not work under normal operating, we provide them for free.

Pictures

Why choose us?

Product quality is guaranteed

Professional team with good service

Complete after-sales service to solve your worries

Complete after-sales service to solve your worries

Related Products

Exhibition

We always provide high quality products and workable price for every clients and have won the trust, enjoy a good reputation in the market.

Machine Quality Guarantee: 24 months.–If any parts broken or does not work under normal operating, we provide them for free:

—

Marcus Wang

Area Sales Manager

Machine Quality Guarantee: 24 months.–If any parts broken or does not work under normal operating, we provide them for free:

—

Marcus Wang

Area Sales Manager

Other Products

Reviews

There are no reviews yet.