| 1. The complex process can be simplified, and the overall efficiency is 3-4 times, which has a large cost advantage. |

| 2. There is no need to change the vibration plate in the scope of the terminal, and instantly change the specifications of different terminals. |

| 3. The threaded peeling pressure is completed in one time, mainly for the pressure connection of the international standard pipe terminal. |

| 4. The line extension is used to make the threading convenient. |

| 5. The strip diameter is automatically adjusted and the pressure height is adjusted automatically. |

| 6. Sensitive pneumatic induction control is adopted, and the pressure is fast. |

| 7. It is convenient and quick to replace the terminals by using vibrating disk feeding mode. |

| 8. Adopting imported components, the cylinder performance is stable. |

1:tubular terminal,bulk insulated terminal

2:0.5/0.75/1.0/1.5/2.5/4 mm2 BVR hard cable

3:Insulator length ≤7.5mm,Conductor length ≤10mm

| Model | YH-4.0D |

| Operation mode | Automatic trigger operation and manual operation |

| Wire size | BVR wire 0.5,0.75,1.0,1.5,2.5,4.0mm2 |

| Stripping length | Max.17mm |

| Terminal size | Insulator length ≤7.5mm,conductor length≤10mm |

| Crimp Shape | Quadrilateral Crimp |

| Production capacity | 2.5s /wire |

| Air supply | 0.6-0.8Mpa |

| Working temperature | 10~25℃ |

| Power source | AC220V/110V/50/60HZ |

| Weight | 40KG |

| Dimensions | W350mm×L450mm×H400mm |

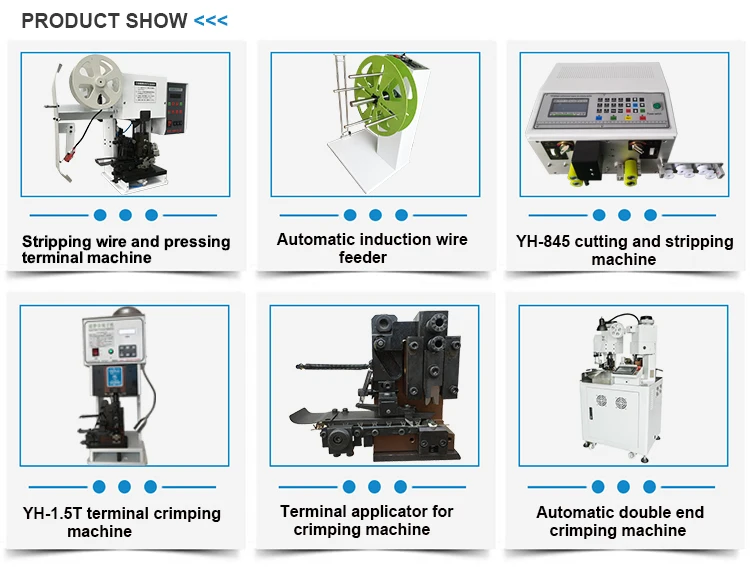

Product Show

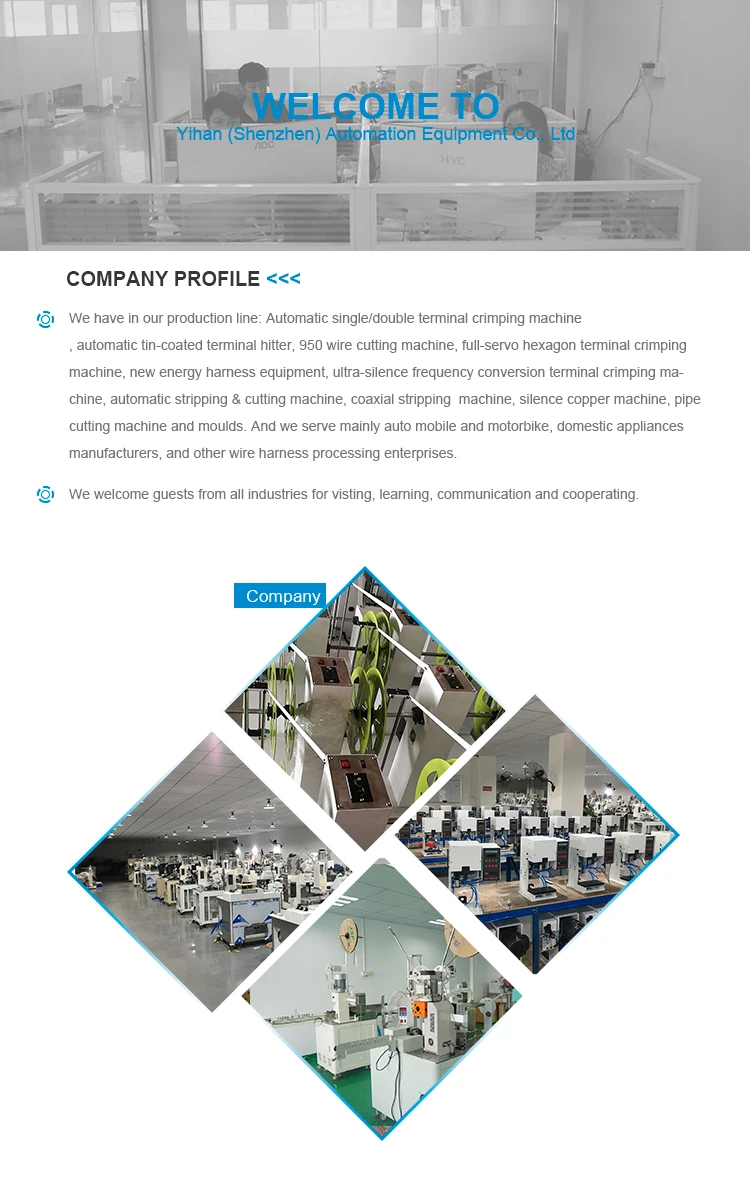

Company profile

Reviews

There are no reviews yet.