New design automatic toilet paper embossed rewinding machine small toilet tissue paper making machine

This machine adopts international new PLC computer programming technology (system can be upgraded), frequency control, automatic electronic brake. The touch-type human-machine interface operating system uses a coreless rewind forming system. application the PLC program wind column forming technology achieves the characteristics of faster rewinding and more beautiful molding.

|

Machine Model

|

1575/1880/2400/3000

|

|

Paper Width(mm)

|

1750mm/2200mm/2400mm/3000mm

|

|

Paper Diameter(mm)

|

φ12100mm(Please Specify)

|

|

Paper Core Inner Diameter

|

φ76mm(Please Specify)

|

|

Product Diameter

|

φ40mm-200mm

|

|

Paper Backing

|

1-4layer,general chain feed or continuously variable transmission feed paper

|

|

Punch

|

2-4 Knife,Spiral Cutter Line

|

|

Hole Pitch

|

Positioning of Belt and Chain Wheel

|

|

Control System

|

PLC Control,Variable Frequency Speed Control,Touch Screen Operation

|

|

Product Range

|

Core Paper,Non Core Roll Paper

|

|

Drop Tube

|

Manual,Automatic(Optional)

|

|

Non core roll paper

|

automtic core pulling

|

|

Production Speed

|

150-280m/min

|

Working Principle

Four-roller automatic feeding→synchronous conveying→embossing→punching→automatic winding→cutting→packing→sealing.

1. Rewinding—The main purpose of the toilet paper rewinding machine is to process the large shaft paper into a long strip of toilet paper roll.

2. Cut the paper—The long piece of toilet paper cut by the paper cutter is cut into semi-finished products of the length

required by the customer.

3. Packaging—Packaging can be packaged in a packaging machine or manually wrapped, and the semi-finished products of the toilet paper are packaged and sealed by a sealing machine.

Four-roller automatic feeding→synchronous conveying→embossing→punching→automatic winding→cutting→packing→sealing.

1. Rewinding—The main purpose of the toilet paper rewinding machine is to process the large shaft paper into a long strip of toilet paper roll.

2. Cut the paper—The long piece of toilet paper cut by the paper cutter is cut into semi-finished products of the length

required by the customer.

3. Packaging—Packaging can be packaged in a packaging machine or manually wrapped, and the semi-finished products of the toilet paper are packaged and sealed by a sealing machine.

Performance Characteristics

1. Using PLC computer to program the finished paper in the rewinding process to achieve the tightness and looseness of the different tightness to solve the looseness of the finished product due to long-term storage.

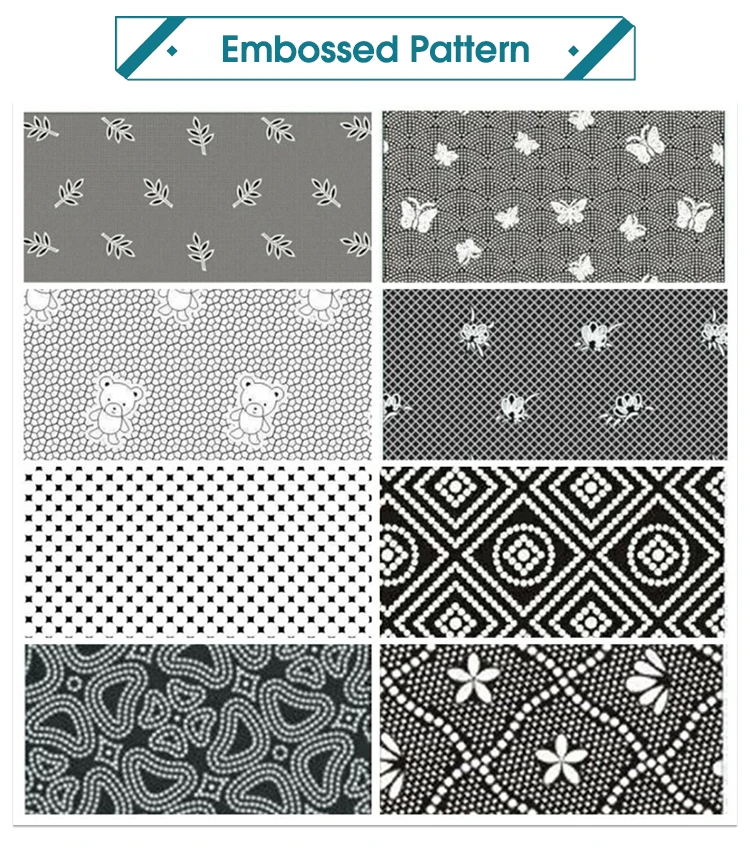

2. Full-automatic rewinding machine can choose double-sided embossing, gluing compound, which can make paper more soft than single-sided embossing, the effect of double-sided finished products is consistent, and each layer of paper does not spread when used, especially suitable for processing. Roll up kitchen paper towels and reduce weight by 15% or more when finished in the same size.

3. The machine is equipped with processing unintentional, solid, paper tube toilet paper, which can instantly switch between products, and can also be selected according to user needs.

4. Automatic trimming, glue spraying, sealing, and shafting are completed synchronously, so that there is no paper loss when the roll paper is cut into the band saw and packaged, which greatly improves the production efficiency and the grade of the finished product. Easy to enable.

5. Pneumatic belt feeding, double reel and each axis of the original paper have independent tension adjustment mechanism

1. Using PLC computer to program the finished paper in the rewinding process to achieve the tightness and looseness of the different tightness to solve the looseness of the finished product due to long-term storage.

2. Full-automatic rewinding machine can choose double-sided embossing, gluing compound, which can make paper more soft than single-sided embossing, the effect of double-sided finished products is consistent, and each layer of paper does not spread when used, especially suitable for processing. Roll up kitchen paper towels and reduce weight by 15% or more when finished in the same size.

3. The machine is equipped with processing unintentional, solid, paper tube toilet paper, which can instantly switch between products, and can also be selected according to user needs.

4. Automatic trimming, glue spraying, sealing, and shafting are completed synchronously, so that there is no paper loss when the roll paper is cut into the band saw and packaged, which greatly improves the production efficiency and the grade of the finished product. Easy to enable.

5. Pneumatic belt feeding, double reel and each axis of the original paper have independent tension adjustment mechanism

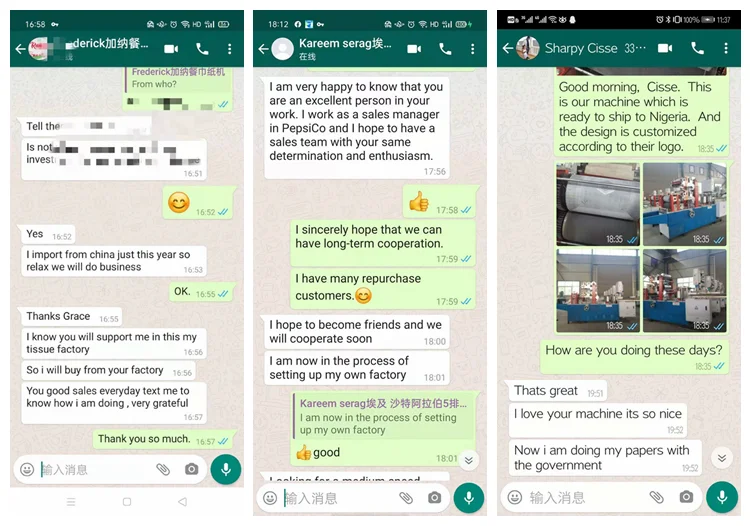

Henan Young Bamboo Industry Co., Ltd.

specializes in the production of household paper towel machines, toilet paper machines, napkin machines, facial tissue machines, egg tray machines and other paper machines and pulp molding equipment. The company covers an area of 10,000 square meters and has nearly 30 years of experience in R&D and export. We always adhere to the principle of quality first, meet customer needs as the purpose, continue technological innovation and development, and provide customers with the highest quality products, reasonable prices and comprehensive services. We welcome you to visit and cooperate at any time.

Reviews

There are no reviews yet.