Because of its appearance, often referred to as snail truck.

After the concrete is output, it is usually water washed inside,

to prevent hardening of the concrete, and taking up the space of drum

Main Features

2.Blade is the main components in the mixing plant, serious wear and tear or damage can lead to concrete mixing unevenly.

3.Cleaning system is the main purpose of cleaning the mixing barrel, is also sometimes used to transport on the way to dry mixing drum.

Technical parameter for silicone sealant mixer:

2). In order to improve the mixing uniformity; we use new rotor structure, the rotor and mixing chamber are so close to the

minimum gap which can be adjusted to zero mm,

3). It can reduce the material residues; with oil added channels inside, the overall structure is more reasonable with beautiful appearance, easy to operate.

|

Model

|

GTM-8030

|

GTM-1050

|

|

ower

|

11kw

|

22kw

|

|

Stirring shaft outer diameter

|

420mm

|

650mm

|

|

Reducer model

|

ZQ350-31.5

|

ZQ350-31.5

|

|

Stirring speed

|

35r/min

|

35r/min

|

|

Stirring speed

|

3700*800*750mm

|

6200*1300*1200mm

|

The Features of silicone sealant mixer:

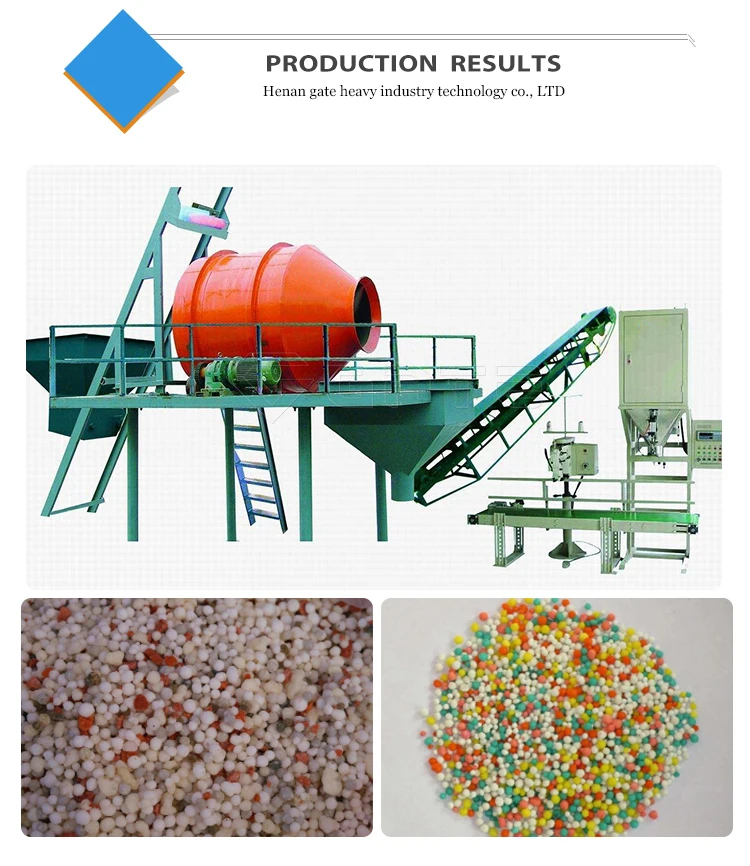

2.Application:organic fertilizer production line,compound fertilizer production line,chemical metallurgy, mining, building

materials and other industries.

3.Capacity:5-8t/h

4.Advantages:The mixing efficiency is high and the area is small.The spiral blade adopts high – wear special alloy;Adopts reducer transmission, which is stable and has low noise;It has reasonable structure;The joint surfaces are tightly sealed and run smoothly.

Reviews

There are no reviews yet.