l 100% payment protection and USD100,000 warrantee by Alibaba.

l Strict quality checking standard according ISO9001:2008.

l With all frequency machine series, also can customized.

l All machines continuously 48 hours testing before shipment.

l Perfect pre and after-sale service and long term technical supporting.

Click here and send us enquiry, Good discount now !

Small Induction Heater , Portable Induction Heating Machine , Induction Heater For Bars (JL-15/25)

Main characteristics

- Adoping MOSFGT and IGBT inverting device, tracking frequency automatically.

- High frequency, heated quickly, its powei consumption is only 20%~30% of eletronic tube induction heating machine and other heating style.

- Security and reliability, the equipments have the secure voltage and it’s secure to operate.

- Manual, automatic regulating automatically, it can protect itself from over voltage, over current, lack of water, phase fail, over hot, etc.

- It has no open-fire, noise and pollution, be suit for the environmental protection and fire, improve the image of the company.

- Recommend usage: Weld, forging, hot cooperate, melting, quenching, anneat etc.

|

Model |

JL-15 |

JL-25 |

|

Input power desire |

Single phase 220V 50/60HZ |

3 phase 380V 50/60HZ |

|

Oscillate power max |

15KW |

25KW |

|

Max input current |

37A |

24A |

|

Oscillate frequency |

30-100KHZ |

30-100KHZ |

|

Cooling water desire |

>0.2MPa 2-6L/Min |

>0.2MPa 2-6L/Min |

|

Duty cycle |

100% 40°C |

100% 40°C |

|

Dimensions(L*W*H) |

500*380*520mm |

550*240*480mm |

|

Net weight |

32kg |

28KG |

|

Cable length |

2-6(Meters) |

2-6(Meters) |

Heating Principle

The principle of high frequency induction heating is that apply high frequency alernating current to a conduct that is curled to cyclic (normally copper tube) to produce flux, then put the metal to this area to make the flux to run through it, and eddy current will be generated in the deriction of self-capturing with flux(rotary current), the induced current then generates heat under the influence of the eddy current, so this heating method is called induction heating. hence, metal and other objects under heated can be heated without contact. at this moment, the character of the eddy current relies in that the induction heating on the object nearby the coil is outwardly strong but inwardly weak. with this principle. this heating body can be concentratedly heated where needed to achieve instantly effect, thereby the production output and work capacity are both improved.

The principle of high frequency induction heating is that apply high frequency alernating current to a conduct that is curled to cyclic (normally copper tube) to produce flux, then put the metal to this area to make the flux to run through it, and eddy current will be generated in the deriction of self-capturing with flux(rotary current), the induced current then generates heat under the influence of the eddy current, so this heating method is called induction heating. hence, metal and other objects under heated can be heated without contact. at this moment, the character of the eddy current relies in that the induction heating on the object nearby the coil is outwardly strong but inwardly weak. with this principle. this heating body can be concentratedly heated where needed to achieve instantly effect, thereby the production output and work capacity are both improved.

Main Parts Introduction:

- Germany SIEMENS INFINEON IGBT Module. ( 40-60KHZ oscillation frequency, fast response time, superhigh stability, almost spatter-free welding )

- Japan Nichicon electrolytic capacitor. ( filter capacitor )

- Imported transistor integrated block.

- All water pipe use thermostability, High pressure resistance best quality material.

- Main card, signal circuit, drive circuit board,control circuit board and components are adopted:Toshiba, Hitachi,Motorola, China’s top manufacturers.

- International advanced all-solid-state semiconductor power devices.

- Technical advantage:perfect control, alarm display circuit, getting full automatic tracking frequency, continuous adjustable power, safe dependable protection,clear and accuracy data display and etc.

- Superiority Advantages: fast heating, wide application, small size, easy installation, simple operation, low power consumption, high efficiency.

Application Showcase

1. Heating & Forging: small rod, plate and billet heating forging for blacksmith, wrought iron etc.

2. Induction Brazing Welding Soldering

Brazing is a fusion and solidification process which refers to the use of magnetic field induction heating to make the temperature of metal materials junction reach the melting point of welding, or the temperature of metal materials to reach between nonmetallic material. Such as metal tube, metal joint, carbide saw blade, carbide tips etc.

3. Melting: small amount metal melting, such as gold, silver, platinum, copper, brass, steel, iron etc.

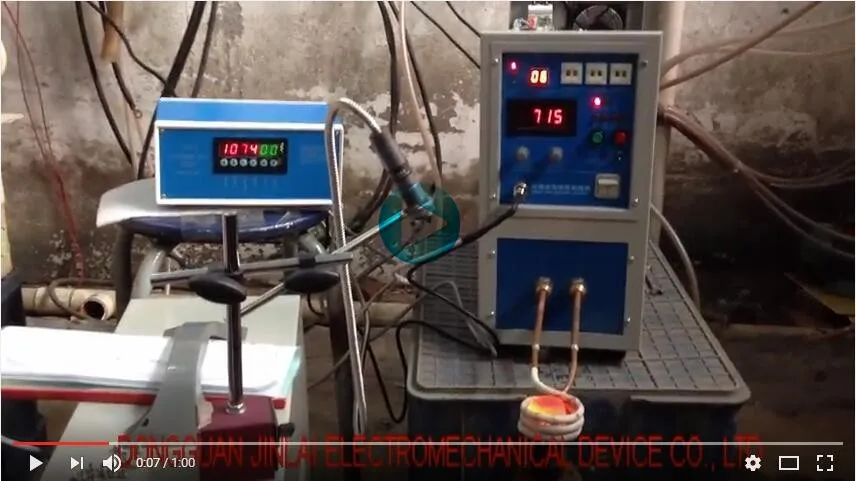

Working Video, for your reference.

How to order ?

1) Kindly tell us your details job requirement, for heating? Brazing? Melting? Forging? Hardening, Annealing? Or ?

2) Confirm the details, then professionally advise you most suitable machine, send the offer to you with all details.

3) Confirm the order and invoice.

4) Receiving your payment, start production. (3-5days)

5) Express/ Air shipment (3-5days) or Sea shipment. (15-30days)

Send inquiry to us, for free to get technical support.

Reviews

There are no reviews yet.