Rubber Plate Vulcanizing Machine Insulation Material Model Pressing Vulcanization Instrumentnizing Machine

Product Overview:

Hot pressing molding machine (also known as plate vulcanizing machine, rubber vulcanization machine, small tablet machine, automatic tablet press) is one of the molding machine, apply to rubber, plastics industry of chemical raw materials

Such as PVC, master batch of mixing processing, the test to determine whether the required color and quality, can be used as the basis of plant ingredients before mass production. The plastic or rubber raw materials are placed in the mold, sandwiching between the upper and lower electric heating plate, and the raw materials are formed by applying pressure under the intelligent constant temperature of the electric heating plate.

Product Features:

The machine has two heating modes, mainly composed of the main engine, hydraulic system and electric control system. The oil tank is installed separately on the left side of the main engine and is not affected by the temperature of the hot plate. The operating valve is installed on the left side of the main engine for easy operation and spacious vision. The electric control box is installed on the right side of the main engine.

Applicable Scope:

It is mainly used for vulcanization of rubber sundry products and water-stop products. It generally adopts column and frame structure. The overall structure is compact, beautiful in shape, and the clamping force is large. The machine is suitable for pressing and shaping of all kinds of reflective materials such as trademarks with its unique double-temperature station structure and high pressure characteristics.

Suitable for rubber and plastic industry.

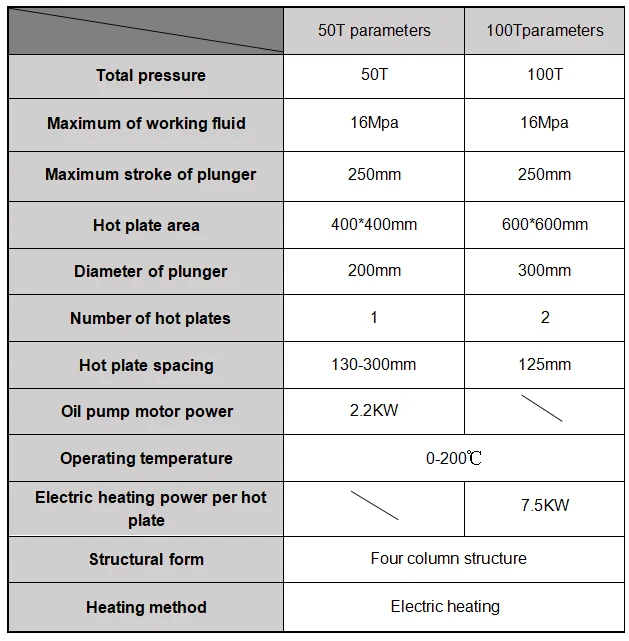

Product parameters:

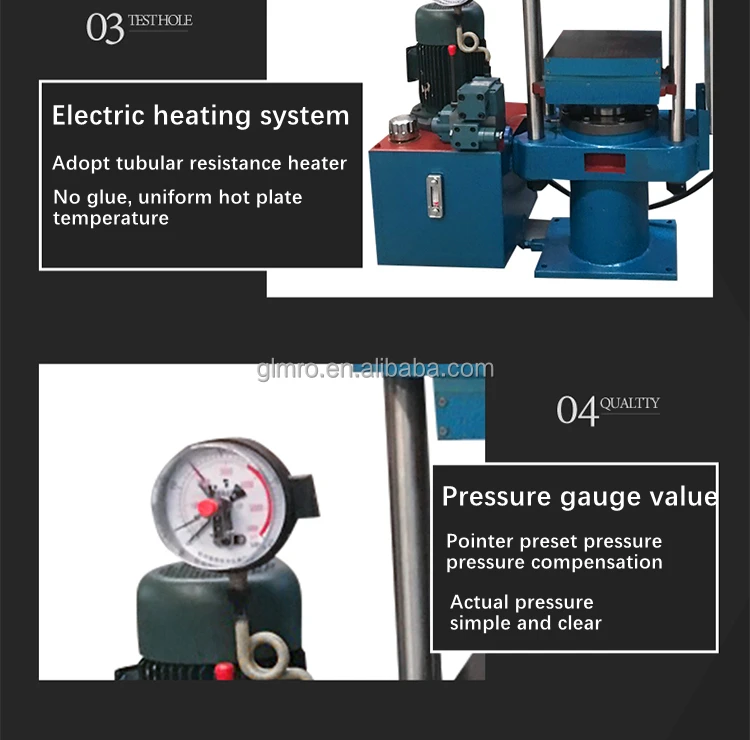

Equipment features:

1. Heater: Built-in heater for electric heating mold, with large power, fast heat conduction and long service life.

2. Temperature sensing rod: it adopts screw-in structure, with sensitive temperature measurement, fast heat sensing and high precision.

3. Electric heating plate: high temperature resistant high quality alloy (electric heating high temperature mold steel), with high hardness, no deformation, fast heat conduction, corrosion resistance and other characteristics.

4. Pressure system: imported oil cylinder and pressure control system, stable pressure, no noise.

1. Aluminium box and carton box, careful and tight package, make sure the package is intact

2. The package will be shipped by DHL/Fedex/TNT/EMS/UPS/China post/EF-Express/Special line, as you have chose in the order.

If you encounter with any problems during the testing process,we promise providing urgent guidence and after-sales sevice within 48 hours and solution providing within 3 working days. If customers require on-site service, the transport and travel expense shall be responsible for the cost.

1. Pre-service

24 Hours online service for customers’ consultation.

2. Middle service

–Fullfill customer’s request:

–Payment method depends on customer.

–Promptly production and delivery

–Can provide invoice value if you want to decrease your tax.

3. After sale service

–One year warranty service and all life maintenance.

–Technical Egineer are avalible for oversea trainning.

–Remote control technical consult

Shanghai Glomro Industrial Co., Ltd was founded in 2012. Specializing in the production of testing equipment and industrial measurements and instruments products. Products of high quality, fashionable, widely used in a variety of industrial areas, not only has the broad masses of the domestic sales market, but also exported to Europe and the United States.

Glomro hinge over the years has always adhered to “quality of products in order to survive, credibility and development services” business purposes. Committed to providing you with high-quality products and quality services. Have a professional, dedicated design management team, from product design, mold making, molding to the Product assembly, for each aspect and processes are rigorously testing and control.

Over the past few years of production and management and exploration, Longtai set up its own quality management system. Industry standards including SAE,IEC JEDEC,ASTM and MIL-STD,ISO:9001,UL,CE certified. Glomro always implement the concept of customer value creation for customers tailored products to meet the needs of different customers, and continuously provide customers with solutions to technical problems,further exploration innovation,and excellence.

Warmly welcome you and opening up the boundaries of communication. We synchronize with your ideal partner!

Q:Are your company a trading one or a factory?

A:Factory + trade (integration),More than 10 years focusing on test instruments field,6 years exporting experience.

Q:After an order is placed, when to deliver?

A:Generally about 10-25days, If we have inventory, we can arrange shipment within 3 days. Please be aware that our production lead times depend on specific items and item quantities.

Q:What about the warranty with after – sales services?

A:The testing machine is guaranteed for 12 months by Shanghai Glomro Building Industrial Co.Ltd ,One year promise including free maintenance and changing Instrument components.Besides, Full-life cycle technical support is provided.

Q:What about the product’ services and quality?

A:Each instruments must be carried out 100% quality examination and test when shipping and delivery goods. each of our product provide video training to show you how to install & operate. We can arrange engineer to train the operation of equipment to customer’s company when you need.

Reviews

There are no reviews yet.