Conveyor, Conveyor, according to the works can be divided into: belt Conveyor, screw Conveyor, bucket elevator, measuring Conveyor, roller Conveyor, chain plate, mesh belt Conveyor, chain Conveyor and belt Conveyor.

Easy to change direction, flexible to change the direction of transport, when large can reach 180 degrees;

Conveyor, each unit is composed of 8 rollers, each unit can be used independently, or multiple units can be connected for convenient installation.

The conveyer can scale freely, and the ratio of a unit length to a short state can reach 3 times.

Conveyor field application mode

First from the tape machine and explain the system: belt conveyor is an important material transporting and handling equipment, can be widely used in mining, metallurgy, building materials, chemical industry, electric power, food processing industries, in coal mines, metals, iron and steel enterprises, ports, cement factories and other places you can see the application of skin machine, transportation machine can not only complete the material conveying, can also be conveyed into pieces of material, but according to use location, working environment, the type of the conveyed material, in its design and application will have bigger difference;

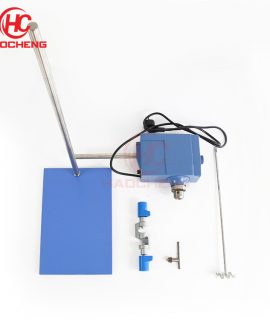

Modernization of conveyor system has higher requirements on dust, therefore, in the transfer is equipped with water spraying dust collecting device, the belt conveyor along with wind cap or wind deflector, the system is composed of a single, to work in the whole system of operation and repair, as well as departmental based on LAN, and understanding the interconnected system, single machine is made up of many parts, only do the daily maintenance of the parts, make its are in good working condition, to ensure the safe operation of equipment;

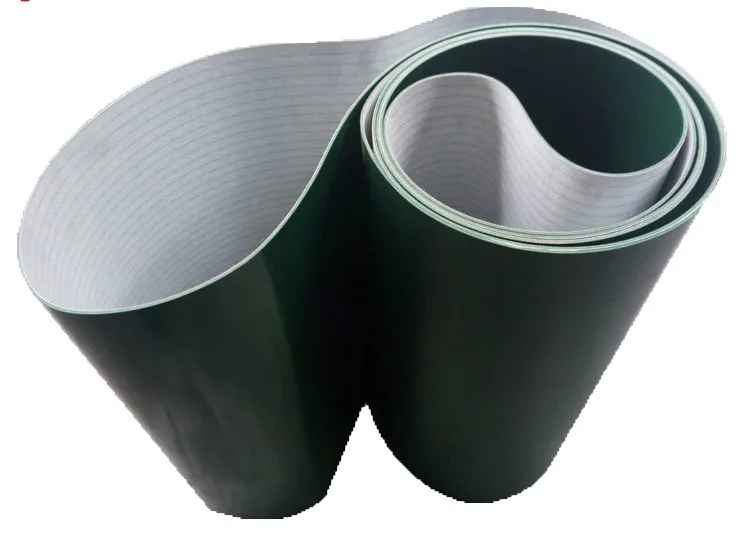

We usually according to the use of belt conveyor, work environment, technical performance and kinds of conveying material aspects of the different, in the form of satisfy a variety of operating mode, in addition to the more with the general belt conveyor, the new structure of a variety of special belt conveyor, one of the representative are: machine big dip Angle belt conveyor, deep groove belt type press and belt type machine, tubular belt conveyor, air cushion belt conveyor, plane turning belt type, line friction type, raised edge conveyor belt corrugated type transport machinery, etc., thinning and there are many classification, we introduce the following:

Classification according to the use, has a general mobile, downhole choose type, opencast stationary, special formula, can displace conveyor, loader is special transfer function type, large Angle conveyor, such as a short conveyor can be finished in the factory level in general, on delivery or shipment, reversible pattern type belt conveyor can be used for two-way conveying material, cantilever machine are normally installed in stacking machine, and rotary, in order to realize the soil or the role of cloth, and the elevated is supported by the door frame machine is usually used with other bulk material handling equipment, such as in hydropower construction, the application of configurable standard middle frame, the frame set on-orbit pillow,Easy to move;

According to transport material categories of classification, there is generally a loose material, hard material and sheet material use of belt conveyor, etc., according to the position of bearing period of rubber conveyor belt to classification, including belt bearing section below as well as in the above and bearing segment and bearing section of the up and down in the three types of two-way conveyor, using two-way conveyor conveying material can respectively under the branches and branches, but in order to keep the material interface does not produce change, need for rubber belt flip on a regular basis.

Main Features

1 simple operation

2 smooth transmission

3 low noise

4. Anti-static and anti-wear

5. Strong bearing capacity, large amount of conveyor, fast speed and stable

Dong Guan SongYa Hardware Machinery Co,.Ltd.

Mainly engaged in research,development production of Automatic Machinery Equipments.

we are a high-end non-standard equipment service provider.

The specialty is engaged in the special test equipment, automated production equipment, testing equipment design and production, as well as tooling, fixture, mold, fixture and process equipment design and manufacturing, and provide non-standard equipment related services.

we provide sassembling, testing, repairing, technical consulting, training services on self-manufacturedproducts.

We founded in 2016 and located in Dongguan city chang’an town, We focus on manufacturing machinery, excellence, continuous innovation, based on the existing technology, the continuous improvement of details, are provided in the actual use repeated verification, maximum limit reduces the failure rate and after-sales maintenance.

We depend on high technology and high quality service, at the same time in the open up foreign markets, actively expand overseas markets.

From 2016 to now, our mechanical equipment exported to various countries, high strength long experience and has received a lot of old customer’s trust and established long-term cooperative relationship. We will uphold the fine style of work in the past, continue to explore the road ahead.

Our factory is committed to the production of conveyor, and we customize the most reasonable production line for customers.OEM OEM is welcome.

Every year, we go to Shanghai to attend the exhibition with the improved machinery and equipment.

At the exhibition, we can learn more about the customer’s needs, and continuously improve the machine according to the customer’s feedback, so as to diversify the functions and meet the customers’ diversified machine requirements.

Provide sustainable improvement programs to make our machines more perfect and more standard.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Reviews

There are no reviews yet.