Products Description

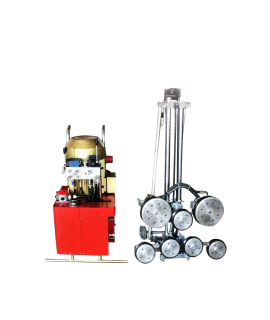

Anchor Drill Rig

The anchor drilling machine is mainly used in the sliding wave control engineering of railway, highway, water conservancy and hydropower facilities, the anchorage engineering of dangerous rock mass, the anchorage engineering of high slope rock mass such as controlling the displacement of buildings, etc. It is also used for the construction of deep foundation pit support and foundation reinforcement engineering holes, water well hole drilling, blasting engineering holes and tunnel pipe shed support holes. It is characteristic of compact structure, small size, light weight, flexible, and wide application. You can choose different models of this drilling rig according to your construction requirements and geological conditions to achieve the best drilling efficiency.

Features

1. Full hydraulically driven, easy-operation, flexible, easy-shifting, good maneuverability, time- and effort-saving.

2.The rig gyrator is driven by a double hydraulic motor and has a large output torque, which greatly improves the drilling

stability of the rig.

3. The new variable angle mechanism makes the hole more convenient and the adjustment range becomes larger, which can reduce the requirement on the working face.

4. Equipped with a special heel drilling tool (drill pipe, sleeve, eccentric drill bit, etc.), with a casing wall opening in an

unstable formation, a conventional ball tooth bit hole.

5. The drilling rig is composed of three parts: main engine, hydraulic station and operation console. It has good detachability and is easy to change. The main mast can be directly connected with the hydraulic station, and the structure is simple. The hydraulic station frame is equipped with rollers for easy movement and relocation.

2.The rig gyrator is driven by a double hydraulic motor and has a large output torque, which greatly improves the drilling

stability of the rig.

3. The new variable angle mechanism makes the hole more convenient and the adjustment range becomes larger, which can reduce the requirement on the working face.

4. Equipped with a special heel drilling tool (drill pipe, sleeve, eccentric drill bit, etc.), with a casing wall opening in an

unstable formation, a conventional ball tooth bit hole.

5. The drilling rig is composed of three parts: main engine, hydraulic station and operation console. It has good detachability and is easy to change. The main mast can be directly connected with the hydraulic station, and the structure is simple. The hydraulic station frame is equipped with rollers for easy movement and relocation.

Detailed Images

Technical Parameters

|

Usage Information

|

||||||

|

Drilling diameter

|

150~250mm

|

Rock hardness

|

f=6~20

|

|||

|

Drilling depth

|

130~170m

|

Drilling rod diameter

|

φ73,φ89,φ102,φ114

|

|||

|

Gradeability

|

25°

|

Working dimension

|

3600*2500*5600mm

|

|||

|

Delivery dimension

|

5400*2100*2000mm

|

Weight

|

6000Kg

|

|||

|

Power Configuration

|

||||||

|

Power

|

55Kw+18.5Kw

|

Voltage

|

380V

|

|||

|

Power Head

|

||||||

|

7500Output torque

|

2960N.m

|

Output speed

|

10~170rpm

|

|||

|

Thruster

|

||||||

|

One-time advance length

|

3400mm

|

Advance compensation length

|

900mm

|

|||

|

Lift force

|

70KN

|

Propulsion

|

36KN

|

|||

|

Lifting speed

|

0~30m/min

|

Advancing speed

|

0~59m/min

|

|||

|

Drilling Angle

|

||||||

|

Drill arm angle

|

0~90°

|

Climbing angle

|

25°

|

|||

Application

Recommend Products

After Sales Service

Free video instruction;

Telephone instruction;

Factory engineer training

Engineer overseas installation guide;

1 year warranty;

Free lifetime maintenance

24-hour online service for engineers;

Spare parts provided for life;

High price recovery

Contact Us

Reviews

There are no reviews yet.