Basic Purpose

Products Description

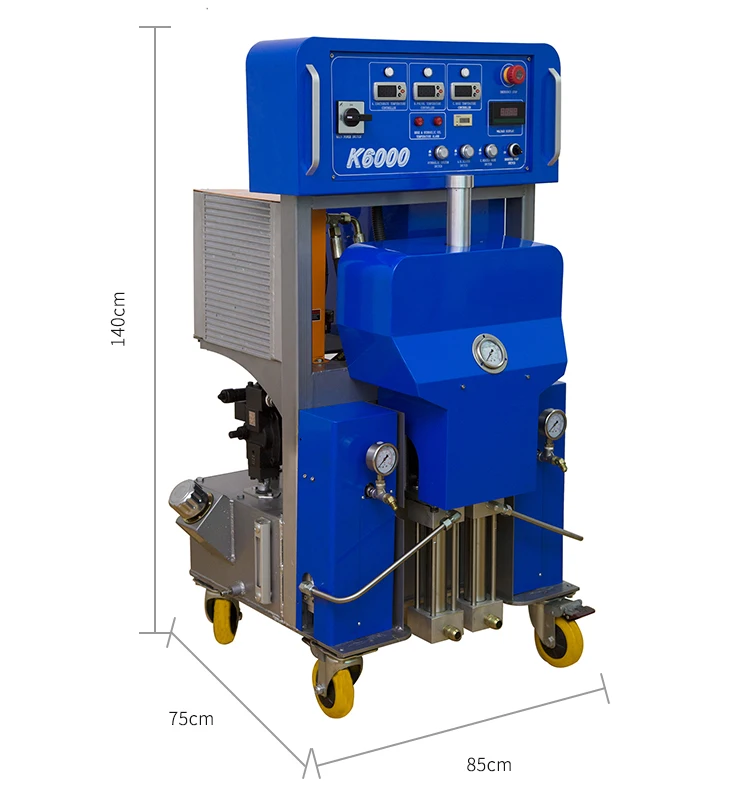

Reanin-K6000 is a hydraulically driven polyurethane polyurea spray machine. It has the characteristics high working pressure, stable pressure and large spray output. It is especially suitable for large-scale spraying construction.

|

Product parameters

|

||

|

Model

|

Reanin-K6000 polyurethane and polyurea spray machine

|

|

|

Applicable materials

|

Polyurethane and Polyurea

|

|

|

The ratio of raw material

|

1:1

|

|

|

Viscosity range of raw materials

|

200-1000CPS (under working temperature)

|

|

|

Max working pressure

|

30MPa

|

|

|

Max fluid temperature

|

80°C

|

|

|

Max output

|

15kg/min

|

|

|

Max heated hose length (Optional)

|

90m

|

|

|

Heater power

|

4500W×2

|

|

|

Heated hose max power

|

3000W

|

|

|

Drive mode

|

Hydraulic

|

|

|

Clean mode

|

Self-cleaning by air

|

|

|

Voltage (Optional)

|

Three phase 220V 60Hz or Three phase 380V 50Hz

|

|

|

Whole power

|

17kw

|

|

|

Pneumatic source

|

0.5-0.8Mpa 1m³/min

|

|

|

Standard configuration

|

||

|

Reanin-K6000 mainframe

|

1 set

|

|

|

Reanin spray gun

|

1 set

|

|

|

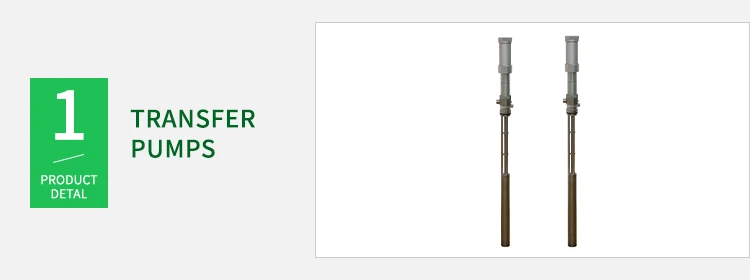

Transfer pump

|

2 sets

|

|

|

Heated hose

|

15m

|

|

|

Transfer pump hose

|

2 pcs

|

|

|

Whip hose

|

2 pcs

|

|

|

Air pipe

|

1 set

|

|

|

Tools and spare parts

|

1 set

|

|

|

English user manual

|

1 set

|

|

|

Transportation Parameters (Based on standard configuration)

|

||

|

Model

|

Reanin-K6000 Polyurethane and polyurea Spray Machine

|

|

|

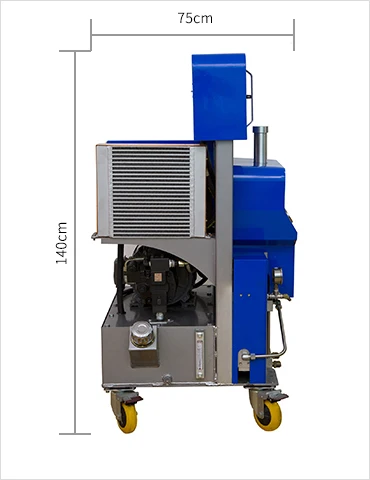

Package size (LXWXH)

|

120X90X155cm

|

|

|

Net weight

|

329kg

|

|

|

Gross weight

|

397kg

|

|

How It Works

Detailed Images

Advantages

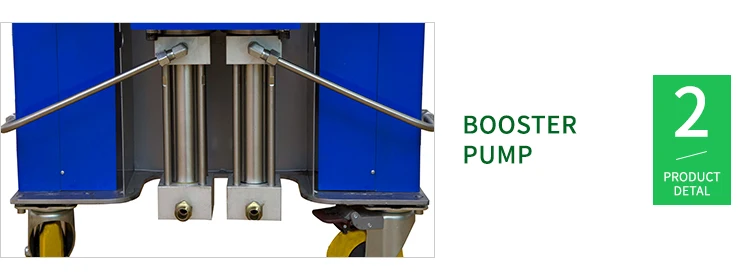

1.This machine has pass the CE certificate, 2.Panel with operation tips is easy to set up, 3.Equipped with hydraulic station, the working pressure is stable, and the effect of continuous spraying for a long time is good, 4.The high-speed circulating lubricating fluid in the anti-curing lubrication cylinder can quickly take away the leakage of materials, and the ISO pump shaft is always immersed in the lubricating fluid to avoid crystallization, 5.A/B/Hose independent temperature control, can set different temperatures separately, adapt to the temperature requirements of different materials, 6.Variable frequency temperature control mode and special real-time temperature collection sensor ensure that the material temperature is controlled within a small fluctuation range, 7.The heated hose is wrapped around the heating belt, the heating is fast and uniform, and covered with the insulation and protective cover, which is safe and durable, 8.The transfer pumps, mainframe and spray gun are equipped with filtering devices, which can effectively filter impurities and crystals in the materials and reduce the occurrence of the blocking gun, 9.High-precision pressure gauges are available in MPA and PSI to meet the needs of different customers, 10.Equipped with an action counter to accurately calculate the amount of raw materials, 11.The spray gun is made of alloy material, light weight, less wearing parts, easy to use and maintain.

Reviews

There are no reviews yet.