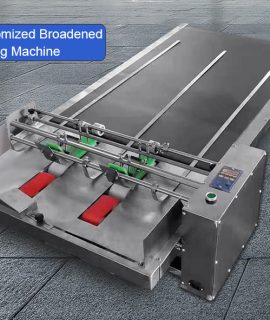

Rack drive, high efficiency, high cost performance CNC woodworking engraving machine

|

Design and typesetting by special engraving software (CAD/CAM) configured in the computer. The computer automatically transmits the design and layout information to the engraving machine control system. The controller then converts this information into a signal (pulse) with power that can drive a stepper motor or a servo motor. Control the carving machine main machine to generate X,Y,Z axis carving tool path. At the same time, the high-speed rotating spindle motor on the engraving machine, through the processing material configuration of the cutter, fixed on the main working table of the processing material for cutting or engraving, can be engraved in the computer design of a variety of plane or three-dimensional relief graphics and text, to achieve automatic engraving operations.

This machine accessories import high quality accessories, the work format is big, the consumption is low, the intelligent operation is easy to control, the installation has the safety protection device, the engraving precision is high, the error is small, the price is cheap, deeply the general consumers love.

|

|

|

Cnc Router Machine 1325 Application

1.This machine is widely used in furniture processing industry, home decoration, wood working decoration,doors manufacturing, wood art craft and so on. it is also widely used in processing for single lines, milling,3D embossing, cutting and engraving etc.

2.Efficient manufacturing of wooden products, advertising billboard, acrylic cutting, letter mold form-ling and mass cutting. Also the machine can engrave on iron, brass, aluminum, plastic and wood boards and other non-metal materials.

|

Main feature

|

1.Water cooling spindle,high precision,long life time,steady working,easy to start up.

2.Thicken square pipe stucture ,well welded, no distortion for whole structure high precision ,and long life time.

3.DSP controller system with USB interface,working without connecting with computer during working and easy to control.

4.Software:CAD/CAM designing software such as type3/artcam/castmate/weitai etc. 5.auto oilling system ,easy to operate by pressing one key. 6.Seperated control system makes operation easily. 7.Adopt high speed stepper motor and drivers,and two motors for Y axis.max speed is 25mm/min.

8.With rotary axis, it suitable to work cylinder material. |

| X,Y,Z Working Area |

1300x2500x200mm (Any other working size can be customized) |

| X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

| Table Surface | T-slot & vacuum working table |

| X,Y,Z Repositioning Accuracy | ±0.03mm |

| Frame | Welded Structure , leg thickness 20mm |

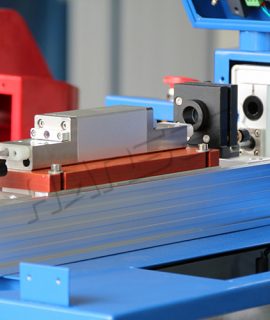

| X, Y Structure |

helical/Oblick rack gear, Taiwan Hiwin linear guide block |

| Z Structure |

Taiwan Hiwin Rail Linear Bearings and Taiwan TBI Ball Screw |

| Max. Power Consumption | (Without Spindle) 2.5kw~3Kw |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working SpeedMax. Working Speed | 25000mm/min |

| Spindle Power | 3.5KW air cooling spindle |

| Spindle Speed | 0-18000RPM |

| Drive Motors | Leadshine motor and driver 758 |

| Working Voltage | AC380V/50/60Hz,3PH (Option: 220V) |

| Command Language | G Code |

| Flash Memory | 512M(U Disk) |

| Operating System | NC-Studio Computer Interface |

| Collet | ER11 ER20 ER25 ER30 |

| X,Y Resolution | <0.01mm |

| Software Compatibility | Type3/Artcam Software(option: Ucancam) |

| Relative Humidity | 30% – 75% |

| Running Environment Temperature | 0 – 45 Centigrade |

|

Packaging Details: 1. Outside package: Standard marine export plywood case. 2. Inner package: Three layers in total; EPE pearl cotton film+PE stretchy film. Improved package, much more strong and environmental protection. We can also make package according to your requests.

Delivery Detail: Shipped in 10-15 working days after payment. |

|

1. We will supply with the machine operation manual in English version for installing and operation.

2.Customer can come to our factory training .

3.Our engineer can go to customer’s factory training.

Warranty and After service 1. Our warranty is 2 years, if parts broken(exclude artificial reason),we will repair or change new.

2. We will supply after service 24 hours,customer can contact us any time.

3.When some problems can’t be solved by customers, our engineer can go to door to help.

|

|

Q. How to use machine? 1. come with the machine,there are english manual and teaching video saved in CD,step by step teach 2.The remote techning support supplied by skype,teamviewer,tm etc 3. Engineer door to door service available,details both side discussed 4. Another other available suggestions can submit

Q. what kind machine do you offer? we senke professional wood,marble,metal,foam etc various cnc routers,Laser engraving and cutting machine,laser marking machine etc.

Q. how shall i choose the models? different models suitable for different materials,just told us, what your mainly materials and size? what the mainly job need the machine do.?we will supply you the best solutions.

Q. tell me about the controller? the commonly use for cnc router including,nc-studio,mach 3,DSP,SYNTEC,LNC etc,user can choice according to their like. |

|

Name: Karma

Email: (Karma @jnhanten.com)

Whasapp: +86-15216357948

(The price of the machine is in the floating stage, if you are interested in our products, please contact me in time, looking forward to your reply.) |

Reviews

There are no reviews yet.