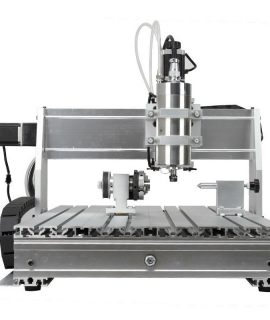

QIPANG torque motor rewind UD tape coreless winding machine without core wire cable tape pipe pneumatic shaft coiling machine

Product Description

New type automatic fax paper cutter is used for slitting and rewinding all kinds of thermal paper, including fax paper,cash register paper,ATM paper,ECG paper,medical record paper,POS paper,self-adhesive trade marks,non-woven cloth,films etc.

1)—It adopts Siemens PLC control system and touch screen, all the parameters are displayed on the monitor, and the machine will automatically work.

2)—It adopts Siemens inverter motor and Yaskawa frequency inverter.

3)—It adopts hydraulic lift-up loading system for heavy materials loading.

4)—It adopts 20kg/m2 RE brand magnetic braking device from Italy.

5)—It adopts balance roller to keep the surface of paper smoothly.

6)—It adopts Tech Mach ultrasonic analog EPC from USA to keep the accurate position.

7)—It adopts Tech Mach floating roller from USA to keep constant control.

8)—All the transmission rollers have been dynamic/static balance treated.

9)—It adopts round blades to slit, the lower round blades are fixed by screws and easy to adjust.

10)—It adopts banana roller to avoid overlap problem.

11)—It adopts auto tucker device, adjusting angle easily.

12)—It adopts auto meter counter, when reaching the setup length, the machine will stop and alarm.

13)—It can avoid overlap of paper reels when finishing slitting.

14)—It adopts red line marking device to print a red line at the end of paper rolls.

15)—New type automatic fax paper cutter adopts scraper to scrape off the ink.

16)—New type automatic fax paper cutter adopts emergency switch.

17)—It adopts 1.5 KW air blower for wasting materials edge trimmer.

2)—It adopts Siemens inverter motor and Yaskawa frequency inverter.

3)—It adopts hydraulic lift-up loading system for heavy materials loading.

4)—It adopts 20kg/m2 RE brand magnetic braking device from Italy.

5)—It adopts balance roller to keep the surface of paper smoothly.

6)—It adopts Tech Mach ultrasonic analog EPC from USA to keep the accurate position.

7)—It adopts Tech Mach floating roller from USA to keep constant control.

8)—All the transmission rollers have been dynamic/static balance treated.

9)—It adopts round blades to slit, the lower round blades are fixed by screws and easy to adjust.

10)—It adopts banana roller to avoid overlap problem.

11)—It adopts auto tucker device, adjusting angle easily.

12)—It adopts auto meter counter, when reaching the setup length, the machine will stop and alarm.

13)—It can avoid overlap of paper reels when finishing slitting.

14)—It adopts red line marking device to print a red line at the end of paper rolls.

15)—New type automatic fax paper cutter adopts scraper to scrape off the ink.

16)—New type automatic fax paper cutter adopts emergency switch.

17)—It adopts 1.5 KW air blower for wasting materials edge trimmer.

|

Max. Unwinding Width

|

Tape 12mm-50mm

|

|

Max. Unwinding Diameter

|

Round wire 2-6mm

|

|

Max. Rewinding Diameter

|

Round wire 2-6mm,Tape 12-50mm

|

|

Min. Slit Width

|

30mm

|

|

Max. Machine Speed

|

0-150m/min

|

|

Unwinding Shaft

|

3” Air Expanding Shaft

|

|

Rewinding Shaft

|

0.5”, 1”are available(or as request)

|

|

Voltage

|

Three-phase,380V,50HZ/Single-phase,120V,60HZ

|

|

Main Power

|

2.2kw

|

|

Weight

|

130KG

|

|

Overall Dimensions(LxWxH)

|

1100x800x1000mm

|

|

Location

|

Indoor.The products should be installed on flat and solid foundation.

|

|

Voltage Regulation

|

±10%

|

|

Frequency Regulation

|

±5%

|

|

Altitude

|

-5°C-40°C

|

3.Specific configuration:

Standard :

Standard :

1. Base Frame: square steel, it is strong

2. 2.pair of tapered tips (compatible with a variety of inner hole bobbin).

3.One power distribution cabinet( include the power supply and Frequency converter).

4.Adjustable speed (120 revolutions per minute, other speeds can be customized)

5.There are 4 fixed expansion screw eyes in the bottom

6.There is anti-slip device at the top, bearing weight 30KG.

7.The winding part choose precision rolling ring drives.

8. 220V power.

3.One power distribution cabinet( include the power supply and Frequency converter).

4.Adjustable speed (120 revolutions per minute, other speeds can be customized)

5.There are 4 fixed expansion screw eyes in the bottom

6.There is anti-slip device at the top, bearing weight 30KG.

7.The winding part choose precision rolling ring drives.

8. 220V power.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

The company was established in 2009. The company's products include various types of winding machines and accessories such as rolling ring drives, coil winding machines, cable winding machines, textile yarn winding machines, and automatic coil transformer winding machines.

Since its establishment, the factory has always adhered to the principle of quality first and has been developing world-class products. Under the effective operation of the quality assurance system, the quality of products and processed products has been continuously improved. Our products have won a good reputation in the industry and won the precious trust between new and old customers. Our products sell well at home and abroad, including Europe, America, Southeast Asia, Middle East and other countries and regions. We pay more attention to the principle of honest management, mutual benefit and customer first. Our company has been

working hard to make it more creative and reliable. We sincerely hope to cooperate with new and old friends to create a brilliant tomorrow!

Since its establishment, the factory has always adhered to the principle of quality first and has been developing world-class products. Under the effective operation of the quality assurance system, the quality of products and processed products has been continuously improved. Our products have won a good reputation in the industry and won the precious trust between new and old customers. Our products sell well at home and abroad, including Europe, America, Southeast Asia, Middle East and other countries and regions. We pay more attention to the principle of honest management, mutual benefit and customer first. Our company has been

working hard to make it more creative and reliable. We sincerely hope to cooperate with new and old friends to create a brilliant tomorrow!

If you have any questions,pls contact Tel/Whatsapp/Skype:+86 13472640466

FAQ

Q1: Are you a factory or trading company?

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading department.

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading department.

Q2: How does the factory ensure products quality?

With Nearly 16 years experience in manufacturing winding machine, we have our own technology develop department and testing department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers to assemble and test machine.

With Nearly 16 years experience in manufacturing winding machine, we have our own technology develop department and testing department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers to assemble and test machine.

Q3:How about your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

Q4: What are your payment terms?

100%TT or prepaid 50% , balance 50% before shipping.

100%TT or prepaid 50% , balance 50% before shipping.

Q5: How can I get my order? How can I know you sent the goods?

We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

Reviews

There are no reviews yet.