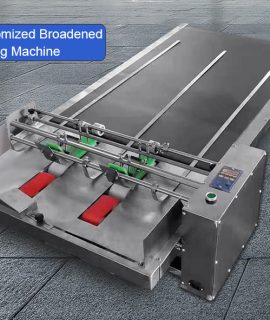

Pneumatic paper cleaning tools carton box waste stripper

The paper waste stripping machine is a pneumatic tool used for the waste edge removal of cardboard, fine corrugated and ordinary corrugated paper in the printing industry. It can replace the manual hammer to eliminate waste, improve work efficiency and shorten the waste elimination cycle.

| Technical Parameters | |

| Model | TPK-P00 |

| Rotating speed | 2500RPM |

| Inlet pressure | 6-8kgs |

| Air consumption | 12CFM |

| Air inlet size | 1/4” |

| Weight | 4.5kg |

| Product Size | 340*140*500mm |

This machine is suitable for the waste edge removal of cardboard, fine corrugated and ordinary corrugated paper in the printing industry.

· Compact structure, light and portable design, easy to use, men and women can be operated with simple training.

·Easy and fast waste, high efficiency, 5-10 times better than traditional manpower cleaning efficiency, greatly shortening the delivery cycle.

·Compared with the hammer knocking method, the bonded parts are not damaged during the stripping, the scrap rate is greatly reduced, and the efficiency of the subsequent process is improved.

·The power source uses a pneumatic motor for safety.

·The tooth chain is made of high-strength alloy steel through heat treatment process, with high hardness, strong wear resistance and long service life.

Description

The Waste Stripper provides a safe,financial|y sound and effective solution for stripping you stacks of cut sheets ,whether these are solid or corrugated board. The waste stripper is equipped with a multi-tooth chain driven by a compressed air motor with an output of 2500R.P.M .lts teeth do not cut the paper,they catch it.Your operator simply needs to hold thedevice, while the waste stripper takes care of the rest—a simle procedure,and incredibly quick.overall,it strips up to 10 times quicker than by hand! To simplify and reduce the operator’s workload,the Waste stripper be equipped wit our load ba|ancer,a support device which compensates for the weight of the waste stripper.the machine operator will then only have to guide the device,without supporting its weight.

Cut stacks often only form one step in the production chain.They must then be conveyed to the quick folder-gluers.Designed to be integrated into your production prooess,the waste stripper makes this task much simpler by quickly stripping the waste,leaving you with clean stacks,ready to be processed by the folder-gluers.

Reviews

There are no reviews yet.