PET Bottle 2 Cavities 500ML and 1000ML Plastic Bottles Blowing Machine Stretch-Blow Molding Machine

Product Description

YDR2, YDR4 are suitable for production type PET bottles of various shapes, volume 200-2000ml. ☞ It adopts double-axis curved arm mold locking, solid mold locking and fast running speed, and adopts far-infrared rotary oven for even heating. ☞ The air circuit system is divided into two parts, action and blowing, in order to meet the demand of different air pressure for action and blowing, and to provide stable high pressure for blowing shaped large volume bottles. ☞ The machine is equipped with a muffler. ☞ The machine is divided into two types: point-action and semi-automatic. ☞ This machine is small in size, low in investment, and easy and safe to operate.

Structure & Technical Parameters

|

Model

|

GD-20 Semi Automatic PET Jar Blowing Machine

|

Dumpling Wrapper Machine

|

|

|

Theoretical output

|

800-1000 pcs/h

|

110v/220V or as request

|

|

|

Finished bottle

|

Max. bottle volume

|

0.2-1.5

|

|

|

Max. neck diameter

|

80mm

|

||

|

Max. bottle diameter

|

110mm

|

||

|

Max. bottle height

|

365mm

|

||

|

Mold specifications

|

Cavity

|

2 cavity

|

|

|

Mold thickness

|

110mm-230mm

|

||

|

Open stroke

|

340mm

|

||

|

Electrical system

|

Power voltage

|

380v/3Phase/50HZ

|

|

|

Installation power

|

25kw

|

||

|

Actual power consumption

|

14kw

|

||

|

Airsource

|

Recommend air compressor

|

1.2m³/min 30Kg

|

|

|

Cooling water

|

Recommend waterchiller

|

3HP

|

|

|

Blowing machine size

|

Length*width*height/weight

|

1630*620*1590mm/650kg

|

|

|

Heater size

|

Length*width*height/weight

|

1780*570*1380mm/350kg

|

|

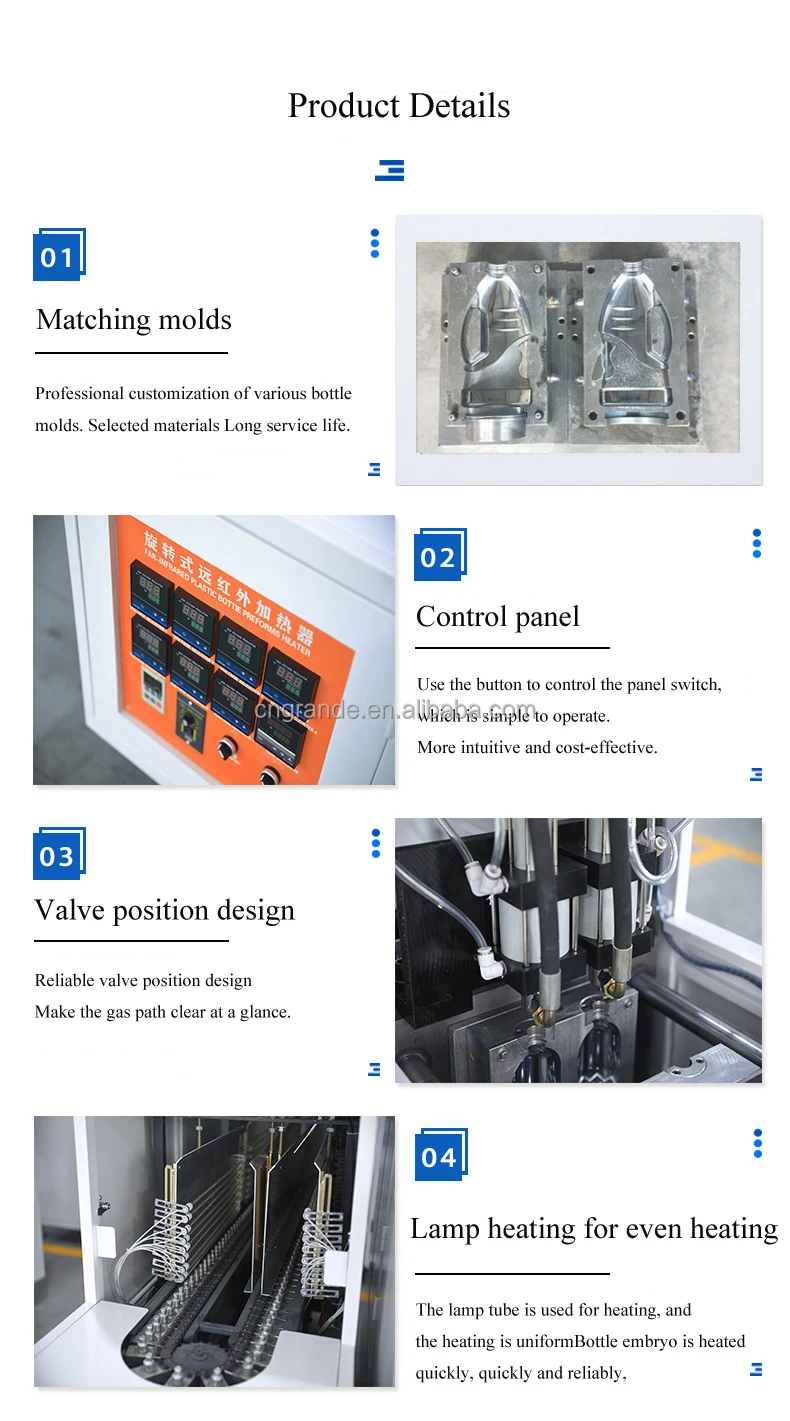

Product Details

Reviews

There are no reviews yet.