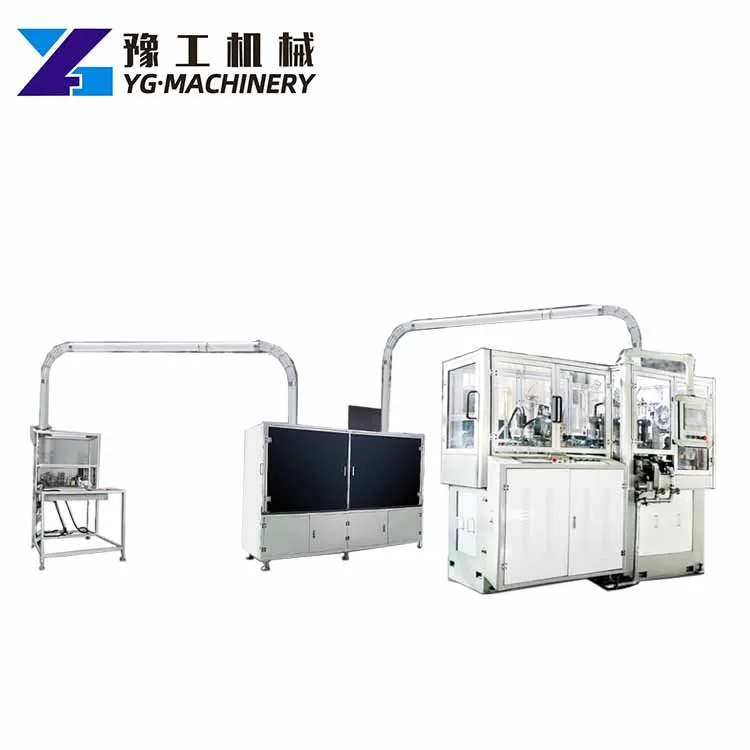

Product Description

Specification

|

Model

|

YG-90

|

|

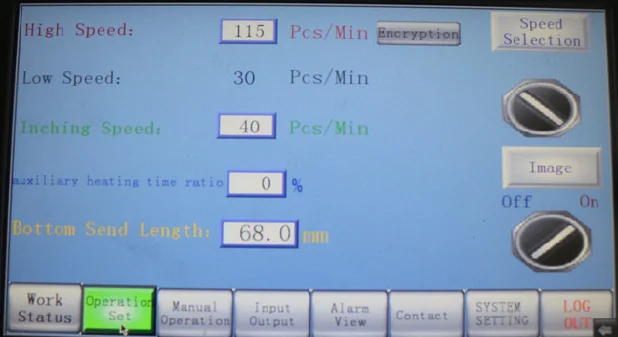

Speed

|

100-120 pcs/min

|

|

Cup size

|

Top Diameter: 60mm(min)-125mm(max)

Bottom Diameter: 45mm(min)-100mm(max)

Height: 60mm(min)-170mm(max)

|

|

Raw material

|

135-450 GRAM

|

|

Configuration

|

ULTRASONIC & HOT AIR SYSTEM

|

|

Output

|

12KW,380V/220V,60HZ/50HZ

|

|

Air compressor

|

0.4 M³/Min 0.5MPA

|

|

Net weight

|

3.4 TONS

|

|

Dimension of machine

|

2500×1800 ×1700 MM

|

|

Dimension of cup collector

|

900 ×900 ×1760 MM

|

Detailed Images

Highlights of paper cup making machine

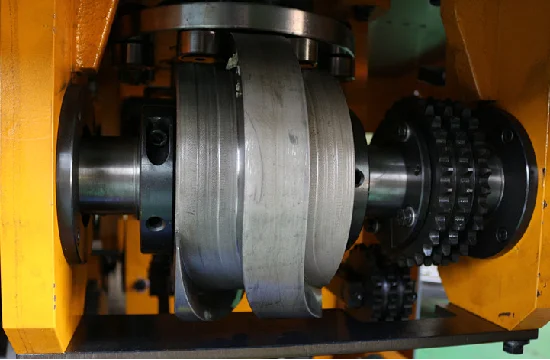

Open cylindrical cam

Two cam systems, this design more costly,

but can let the top curling and bottom knurling more accuracy, stable and low noise.

Cam adpots high strength Japan-SKD11 with quenching treatment,resistant to wear.

but can let the top curling and bottom knurling more accuracy, stable and low noise.

Cam adpots high strength Japan-SKD11 with quenching treatment,resistant to wear.

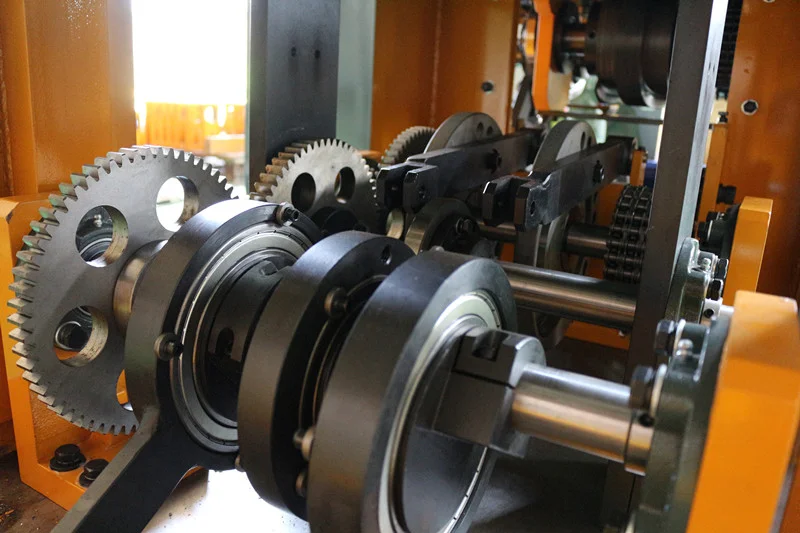

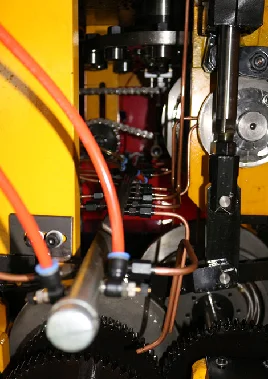

Gear drive

This system ensure the machine runs with high speed with low noise, smoothly running

and high precision. Instead of chain drive.

and high precision. Instead of chain drive.

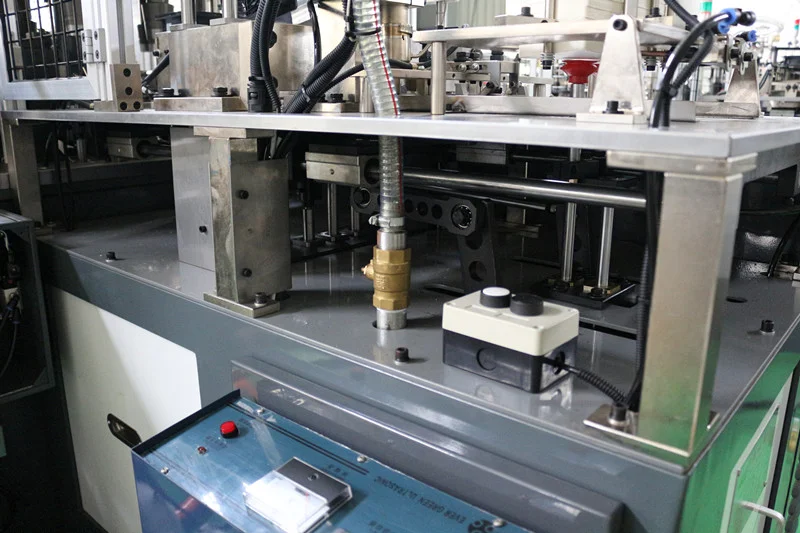

Hot air system and protect system

2 set of hot air systems can decrease the rate of leakage. Our

factory using the whole set of Leister(Banko) hot air system with protection system. And our system

sets up on the fixed plate, do not moving during production. Almost impossible to damage.

Also the only one have the protect system that hot parts will go down, keep the distance with paper

cup and cup mould when the machine stop.

factory using the whole set of Leister(Banko) hot air system with protection system. And our system

sets up on the fixed plate, do not moving during production. Almost impossible to damage.

Also the only one have the protect system that hot parts will go down, keep the distance with paper

cup and cup mould when the machine stop.

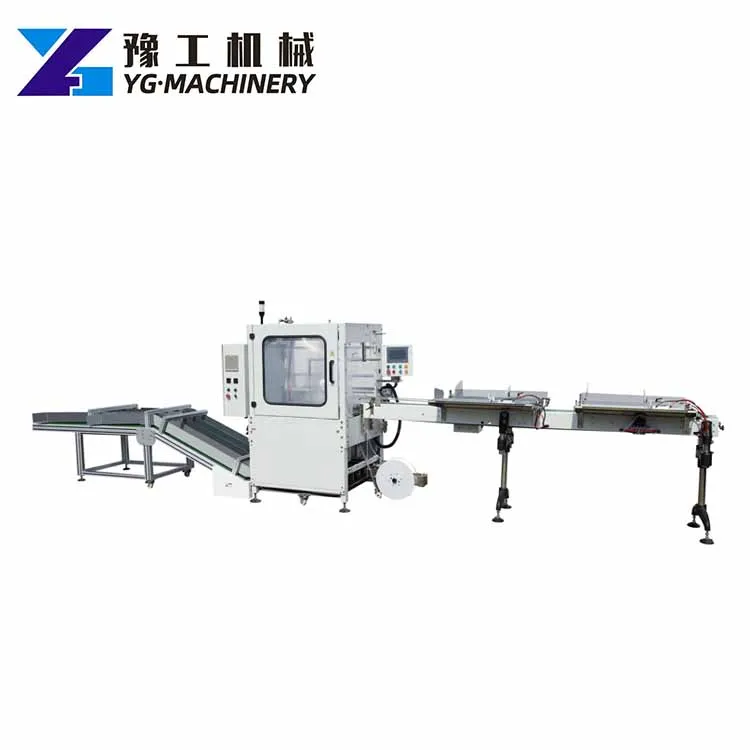

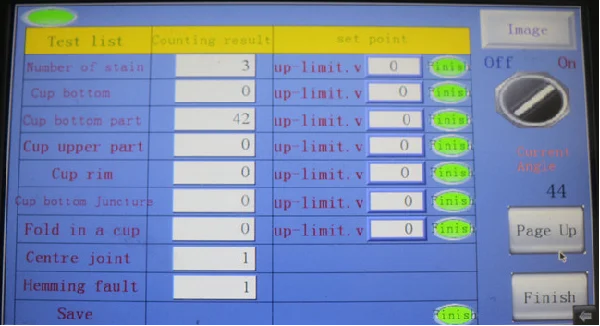

Inspection system

Unique design. Our factory set up on final turn station,more stable than

set up on flying tube. Do not need to buy extra inspection machine, less factory space needed.

Inspection accuracy can be set up by self.

set up on flying tube. Do not need to buy extra inspection machine, less factory space needed.

Inspection accuracy can be set up by self.

Oil lubrication system

Adoptes forced lubrication system to ensure main driving oil supply regularly

and reduce friction and prolong the machine life. The oil circuit adds a clear the oil and filtering system

to clean the oil automaticly. Our factory is the first one to using double layer plate to avoid the scraps

of paper into the machine’s inside.

and reduce friction and prolong the machine life. The oil circuit adds a clear the oil and filtering system

to clean the oil automaticly. Our factory is the first one to using double layer plate to avoid the scraps

of paper into the machine’s inside.

PLC control system

controlled by simple and efficient PLC system

Company Profile

Reviews

There are no reviews yet.