Working Principle

The gear drives the ring gear to rotate, and the volume of the oil suction chamber is from small to large to generate vacuum oil absorption, and the volume of the oil discharge chamber is squeezed from large to small to discharge oil.

Special gear: The tooth profile of the gear is straight, the tooth profile of the ring gear is a linear conjugate line, and there is almost no oil trapping during operation, which greatly reduces the noise and pressure pulsation of the pump.

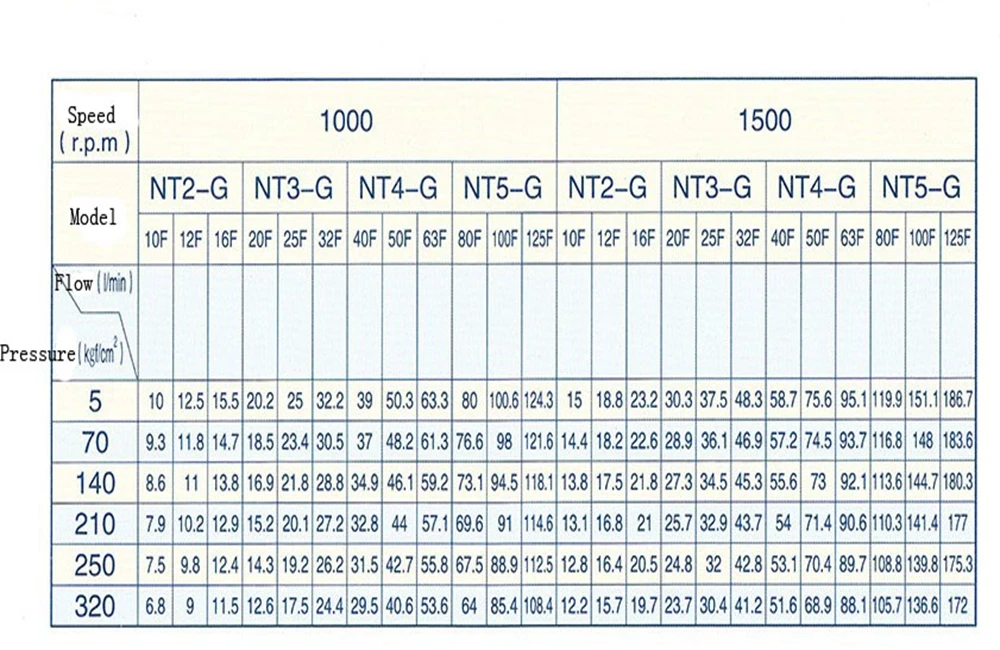

Two-stage boost: the first-stage gear pair inlet pressure is 0Mpa, the second-stage inlet pressure is 12.5Mpa, and the outlet pressure is 25Mpa. When the outlet pressure is 25Mpa, each gear pair only bears a pressure difference of 12.5Mpa, improving the pump. Working conditions extend the life of the pump.

Characteristics

1. Low noise and low pulsation: The special tooth shape design (linear-linear conjugate line) makes the noise and pulsation of the oil pump work greatly reduced.

2, high pressure: using two-stage boost, working pressure up to 25Mpa, the highest pressure up to 32Mpa.

3. Long life: The pressure generated when the oil pump works, the sliding element is forcedly lubricated, and the wear is minimal, which improves the service life of the pump.

Product Usage

Straight-tooth conjugate internal gear pump is an internationally advanced hydraulic power component. It has the advantages of simple structure, low noise, long life and low sensitivity to hydraulic oil pollution. It is widely used in plastic machinery, mining machinery, metallurgical machinery, Petrochemical machinery, precision machine tools, medical equipment and other hydraulic systems, such as: injection molding machine, rubber flat vulcanizing machine, die casting machine, punching machine, brick press and so on.

Product Usage

Straight-tooth conjugate internal gear pump is an internationally advanced hydraulic power component. It has the advantages of simple structure, low noise, long life and low sensitivity to hydraulic oil pollution. It is widely used in plastic machinery, mining machinery, metallurgical machinery, Petrochemical machinery, precision machine tools, medical equipment and other hydraulic systems, such as: injection molding machines, rubber flat vulcanizing machines, die casting machines, punching and shearing machines, brick presses, etc.

Reviews

There are no reviews yet.