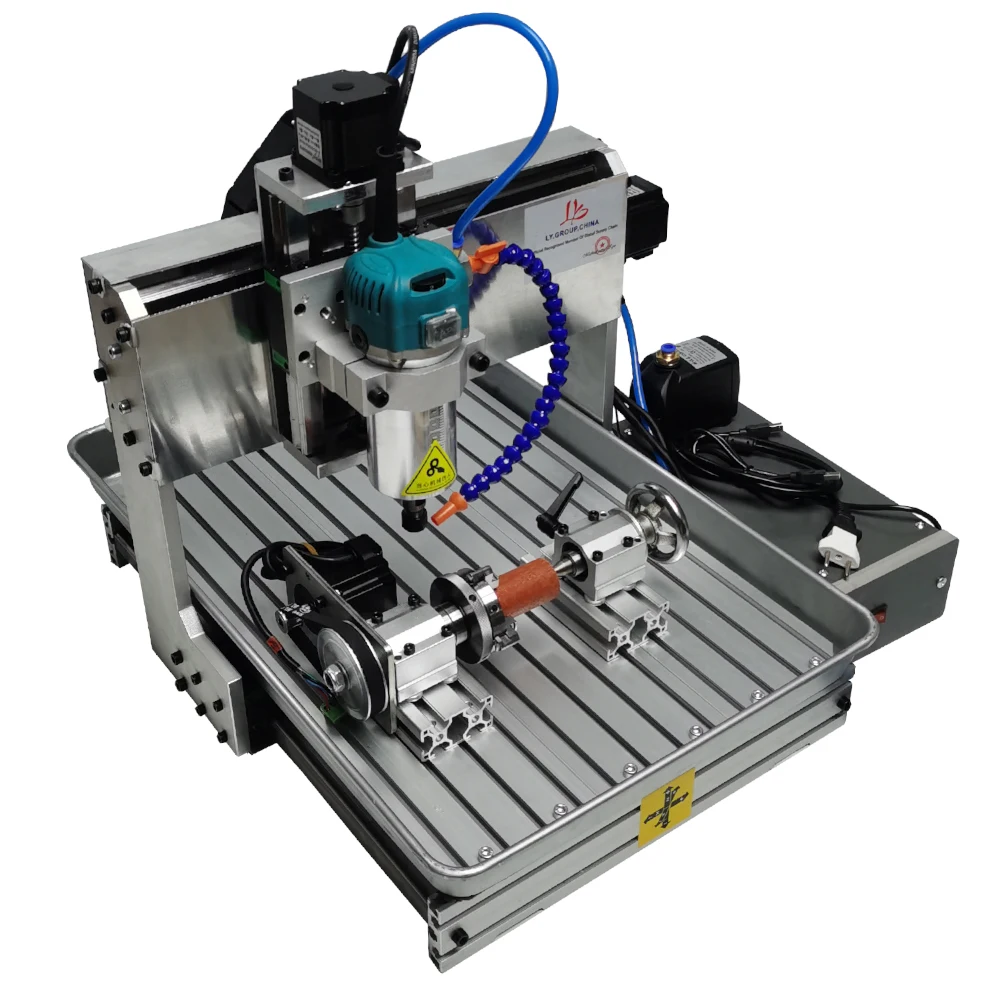

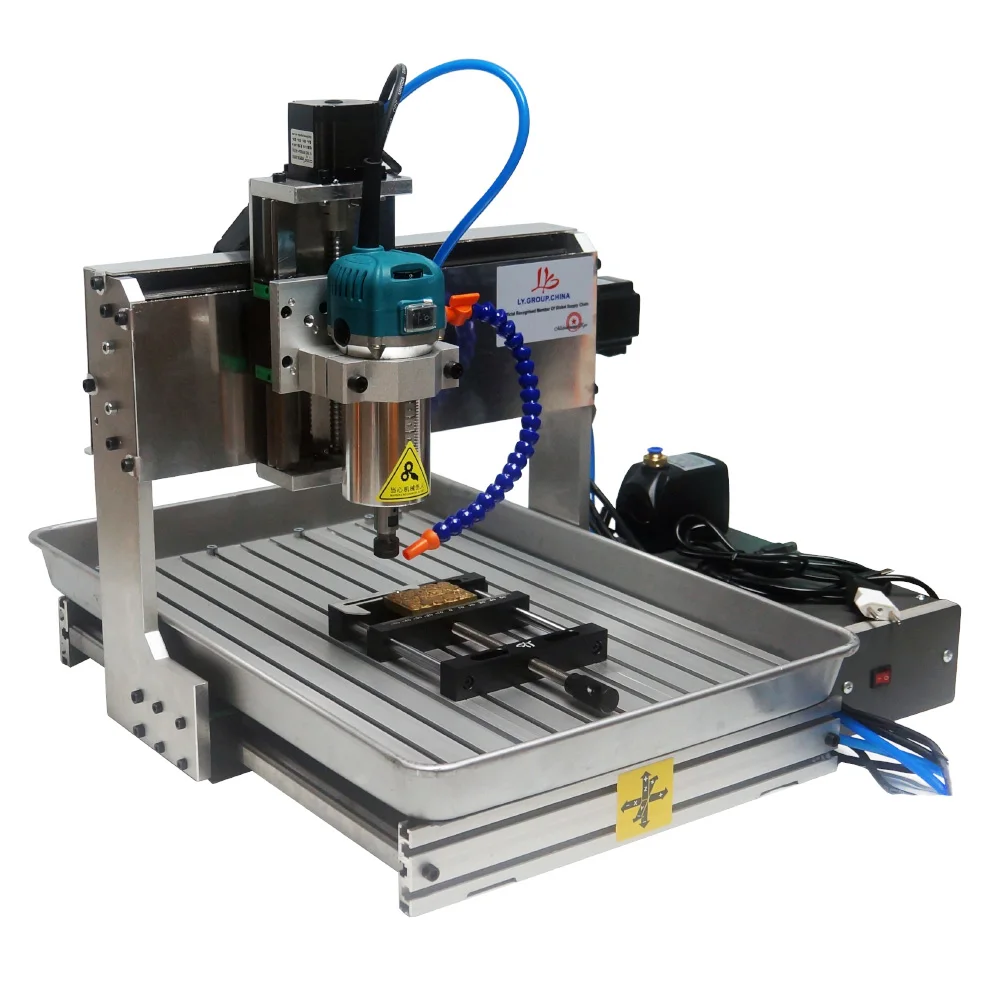

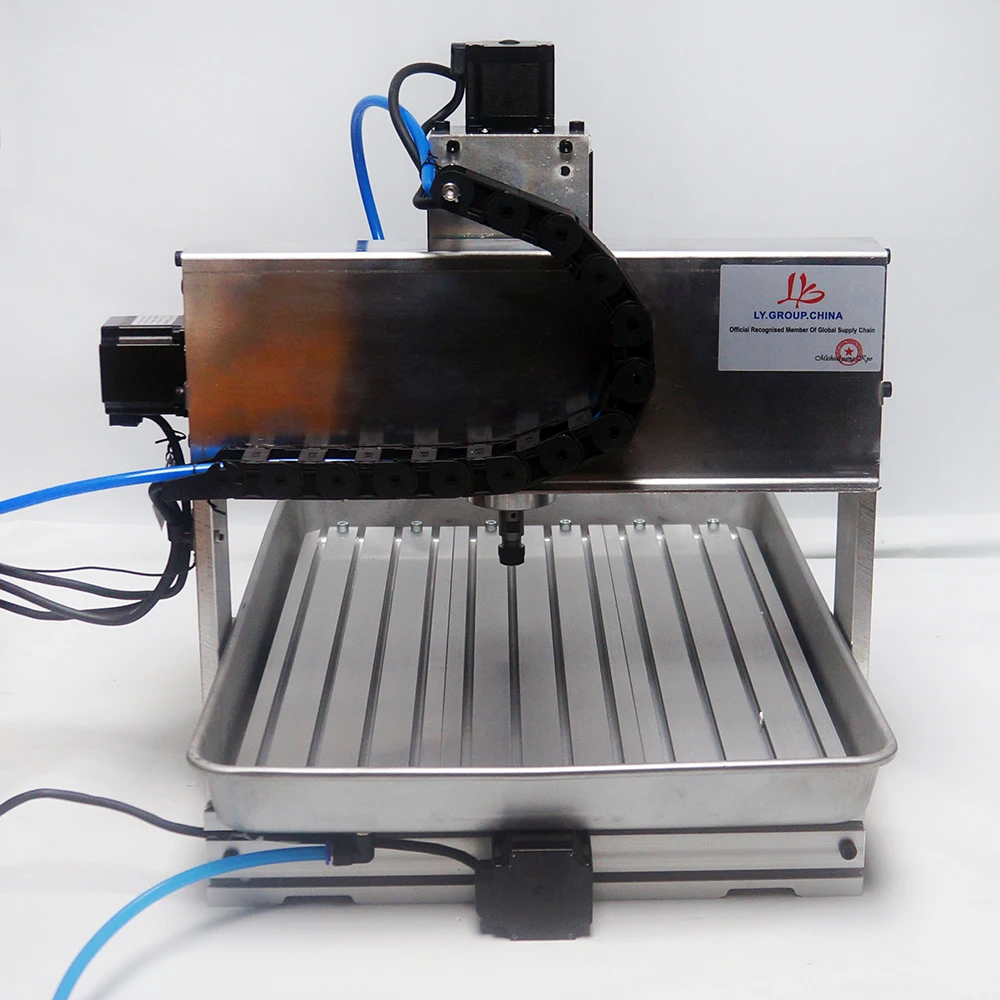

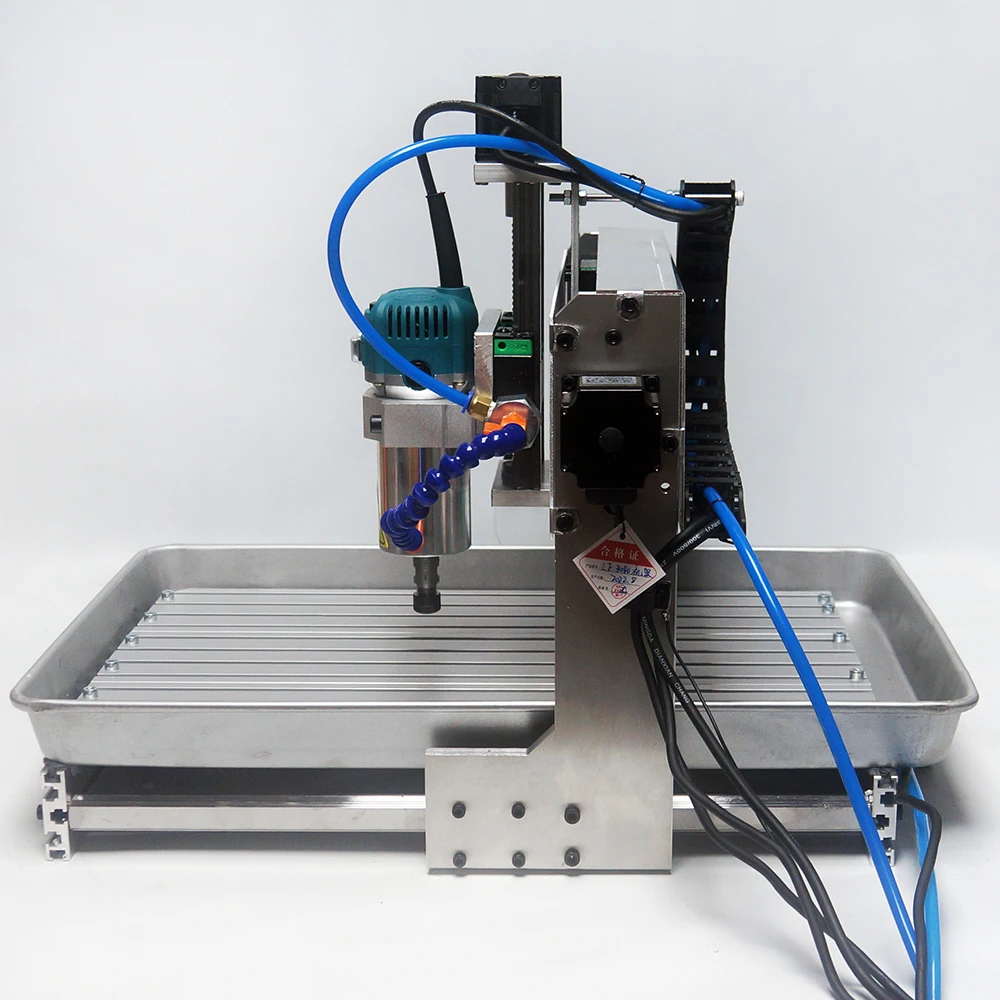

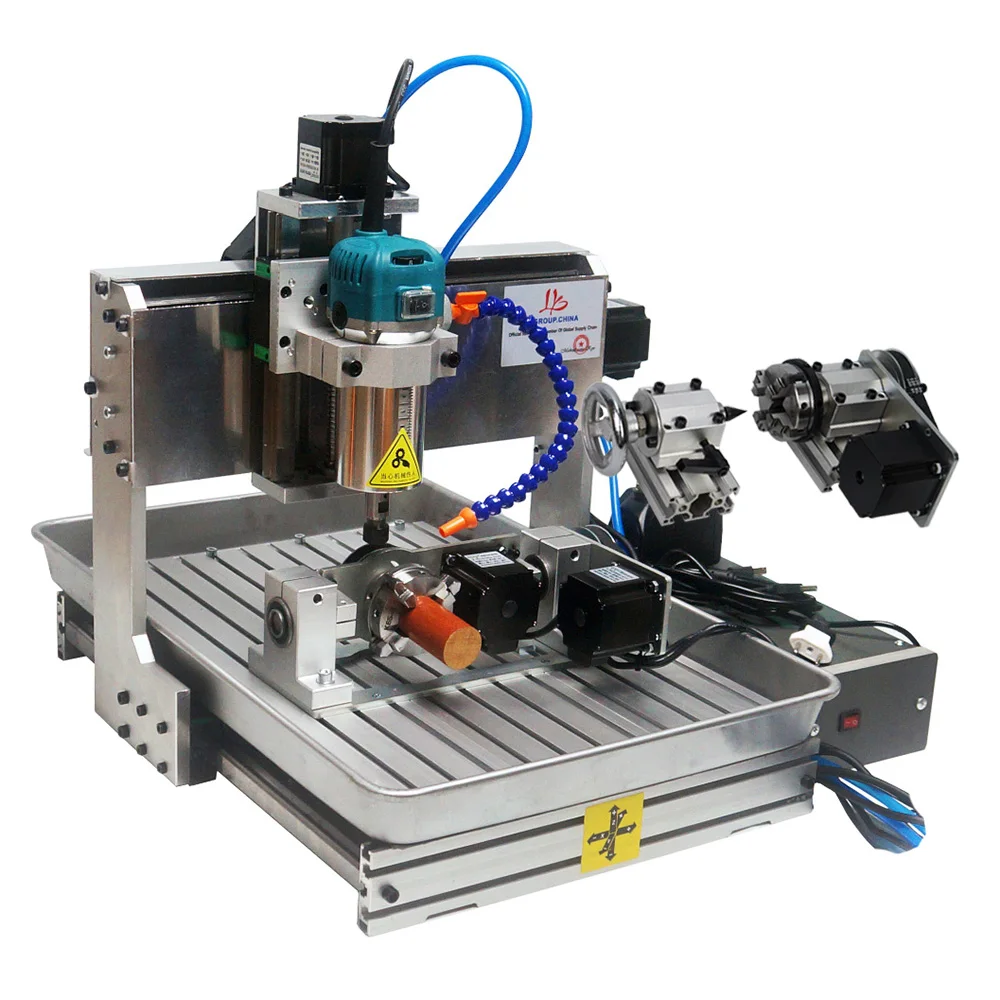

New 5 Axis CNC 6040 Wood Router 1500W 4 Axis Metal Milling Aluminum Engraving Carving Machine 3040 PCB Engraver with Water Tank

Model and Technical Parameters

|

Brand |

LYBGACNC |

|||

|

Model |

LYF2030 |

LYF3040 |

LYF3060 |

LYF4060 |

|

Working stroke (XYZ) mm |

300*400*100 |

300*600*100 |

400*600*100 |

|

|

Machine size cm |

50*40*50 |

62*52*50 |

80*52*50 |

80*60*50 |

|

Weigh |

27 |

31 |

35 |

43 |

|

≤120mm |

||||

|

12~15mm aluminum plate |

||||

|

Table material: |

Aluminum alloy T table + Water tank |

|||

|

Rail type |

X Y 1605 ball screw; Z 1204 ball screw, Square line rail track, three-axis is 20 mm square wire track, |

|||

|

Spindle motor |

1500W Air cooling spindle , 0-30000r/min, 6 speed regulation |

|||

|

Collet type |

ER11,1/8″(3.175mm) Collet |

|||

|

Stepper motor and drive |

||||

|

Repeat positioning Accuracy |

0.02mm |

|||

|

Communication interface |

USB Port |

|||

|

System requirements |

Win-XP / Win 7 Win 8 Win10 |

|||

|

Software Co patability |

Mach3/Emc2/Kcam, (Type3,Wentai, ArtCAM, coppercam) |

|||

|

Command code |

G code/.nc/.ncc/.tab/.txt |

|||

|

4th Axis (Optional) Description: |

Center height: H = 51mm Maximum turning diameter: ≤ 81mm Deceleration ratio: 4:1 Stepper motor: 57HS56 |

|||

|

5th Axis (Optional) Description: |

The fourth axis gear ratio: 4: 1 (57 two phase 3A stepper motor 1.2N) The fifth axis reduction ratio: 5: 1 (57 two phase 3A stepper motor 1.2N) Four jaw chuck 60MM The clamping: Positive direction:40mm; In the opposite direction:70mm Fourth axis Center height: 55MM The fifth axis higher than the 4th axis 44 mm Bottom fixed hole distance: 150mm x 85mm |

|||

Warranty

More Precise Stepping Motor

Simple operation and installation

1 year machine part and 6 months electrical parts,stepping motor,spindle Free Warranty

Precautions for use

1. Beware of potential safety hazards of electricity use. Please ground the rack and take necessary personal protection measures. It should be placed at a place where children can’t touch everyday;

2. The machine is divided into 110 and 220V. Please leave a message when ordering;

3. When the new machine is assembled, the main shaft must be connected to the main shaft output of the control box;

4. After the machine works for a period of time, if the main shaft does not rotate, please check whether the two carbon brushes on the motor are worn;

Reviews

There are no reviews yet.