Product Overview

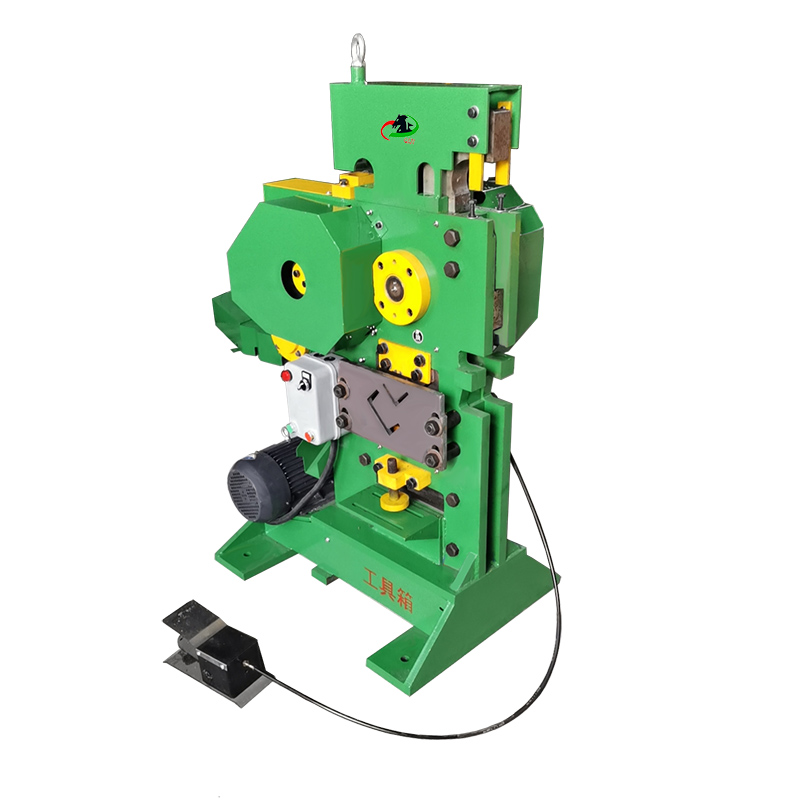

triangular iron Angle cutting, punching and shearing machine

It can cut round steel, angle steel, shear plate, punching and cutting holes. It is the ideal multifunctional manual shearing machine at present. The machine has reasonable design, beautiful appearance, compact structure, stable performance, small size, light weight, multi-purpose machine, flexible operation, convenient use and maintenance, and is widely used for plate and profile Shearing and punching, die cutting work.

1. Steel structure processing

2. Elevator car and parts processing

3. Agricultural and animal husbandry machinery industry — thresher frame and trailer bucket parts processing

4. Machinery for food industry — slaughtering equipment frame and parts processing

5. High and low pressure tower parts processing

6. Wind power equipment — processing of parts for stairs and pedals on wind power towers

7. Mechanical processing — processing of embedded building parts/conveyor supports and other components that play a connecting role

8. Grain machinery — grain and oil equipment starch equipment support, shell, small processing

9. Railway truck/car, crane parts processing

10. Channel steel, square steel, round steel, H steel, I-steel and other steel products shear, punch, bend.

2. Elevator car and parts processing

3. Agricultural and animal husbandry machinery industry — thresher frame and trailer bucket parts processing

4. Machinery for food industry — slaughtering equipment frame and parts processing

5. High and low pressure tower parts processing

6. Wind power equipment — processing of parts for stairs and pedals on wind power towers

7. Mechanical processing — processing of embedded building parts/conveyor supports and other components that play a connecting role

8. Grain machinery — grain and oil equipment starch equipment support, shell, small processing

9. Railway truck/car, crane parts processing

10. Channel steel, square steel, round steel, H steel, I-steel and other steel products shear, punch, bend.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

|

model

|

QJ34-10B

|

|

stamping force

|

360KN

|

|

Scissors length

|

200mm

|

|

power

|

3kw

|

|

frequency

|

50Hz

|

|

Voltage

|

380V(220V/240V)

|

|

Round bar

|

∮35

|

|

Equilateral Angle Steel

|

100*100*10

|

|

steel board

|

200*10

|

|

Channel steel

|

GB-120

|

|

punching

|

∮25/10

|

|

Punched hole

|

40*18*10

|

|

Shaped Angle Steel

|

L50*50*6

|

|

Cut angle steel

|

L50*50*6

|

|

Cutting times of cutter per minute

|

30

|

|

Dimensions

|

1200*600*950

|

|

weight

|

800kg

|

PRODUCT CONFIGURATION

Pure copper motor

Copper core motor has low loss, high efficiency, low noise and long service life.

Cut part

Can cut angle steel, channel steel Round bar.

Shearing knife is polished, and the finished product is smooth.

Flat cut part

Using 9CRSI and 12MOV complete collocation technology production, moderate soft and hard, sharp and durable, long life.

Trimming function

Suitable for channel steel, angle iron, flat iron, iron plate, flat angle shear angle, and other angles.

This machine has the characteristics of high efficiency, fast speed and stable performance.

This machine has the characteristics of high efficiency, fast speed and stable performance.

Punching function

For punching of flat and angle steel.

Round holes or long holes can be customized according to customer requirements.

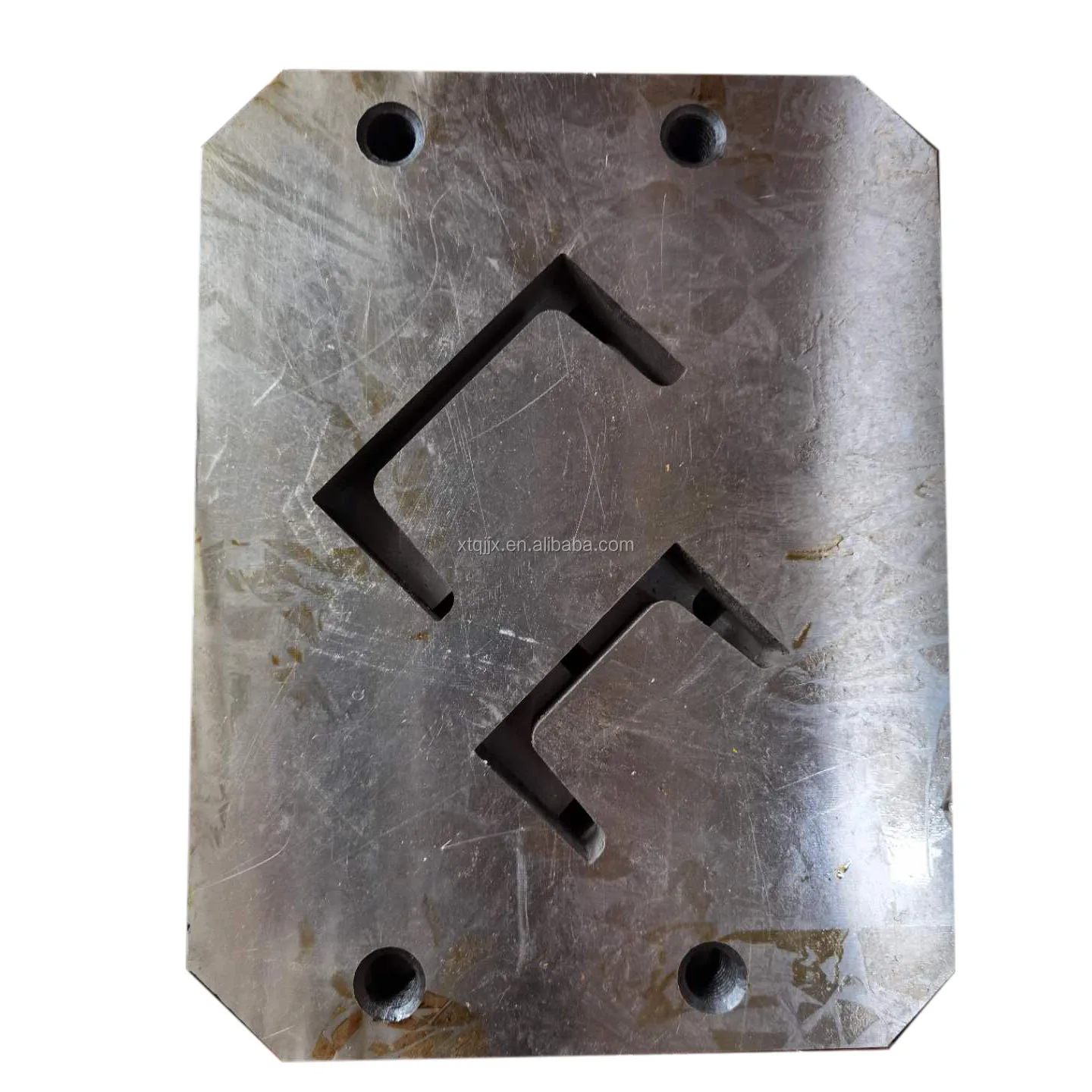

The cutting tool

The mould

SIMILAR PRODUCTS

Product packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

We are a manufacturer and exporter specializing in the design, development and production of construction machinery products. The company is located in Xingtai City with convenient transportation. All our products comply with international quality standards and have passed CE, SGS and other EU certifications. Our products enjoy a good reputation among customers. We welcome friends from business associations around the world to contact us and seek mutually beneficial cooperation.

FAQ

1.Are you manufacture?

ans:Yes, we have more than 15 years of professional manufacturing experience.

2.what is your terms of payment?

ans:Payment terms support TT. credit card. Bank card. LC. Wait for customer service。

3.what is your terms of delivery?

ans:EXW,FOB, CFR, CIF, DDP, DDU.

4.About delivery time?

ans:Shipped within 3-7 days after receiving payment. Except for customized models (you can contact customer service.

5What is the warranty of our machine?

ans:ans:The machine is guaranteed for 12 months and the main parts are guaranteed for 2 years.

6.Do you test att your goods before delivery?

ans:Products will be tested before delivery.

7.What is your terms of packing?

ans:Use fumigation-free wooden box.

8.Do you Preferrde provide wear parts for transacted clients?

ans:We provide customers with wearing parts.

ans:Yes, we have more than 15 years of professional manufacturing experience.

2.what is your terms of payment?

ans:Payment terms support TT. credit card. Bank card. LC. Wait for customer service。

3.what is your terms of delivery?

ans:EXW,FOB, CFR, CIF, DDP, DDU.

4.About delivery time?

ans:Shipped within 3-7 days after receiving payment. Except for customized models (you can contact customer service.

5What is the warranty of our machine?

ans:ans:The machine is guaranteed for 12 months and the main parts are guaranteed for 2 years.

6.Do you test att your goods before delivery?

ans:Products will be tested before delivery.

7.What is your terms of packing?

ans:Use fumigation-free wooden box.

8.Do you Preferrde provide wear parts for transacted clients?

ans:We provide customers with wearing parts.

Reviews

There are no reviews yet.