MOMOTECH Pneumatic / Hydraulic / Electronic

Dual-Station Heat Press Machine

Fully Automatic & Semi-Automatic

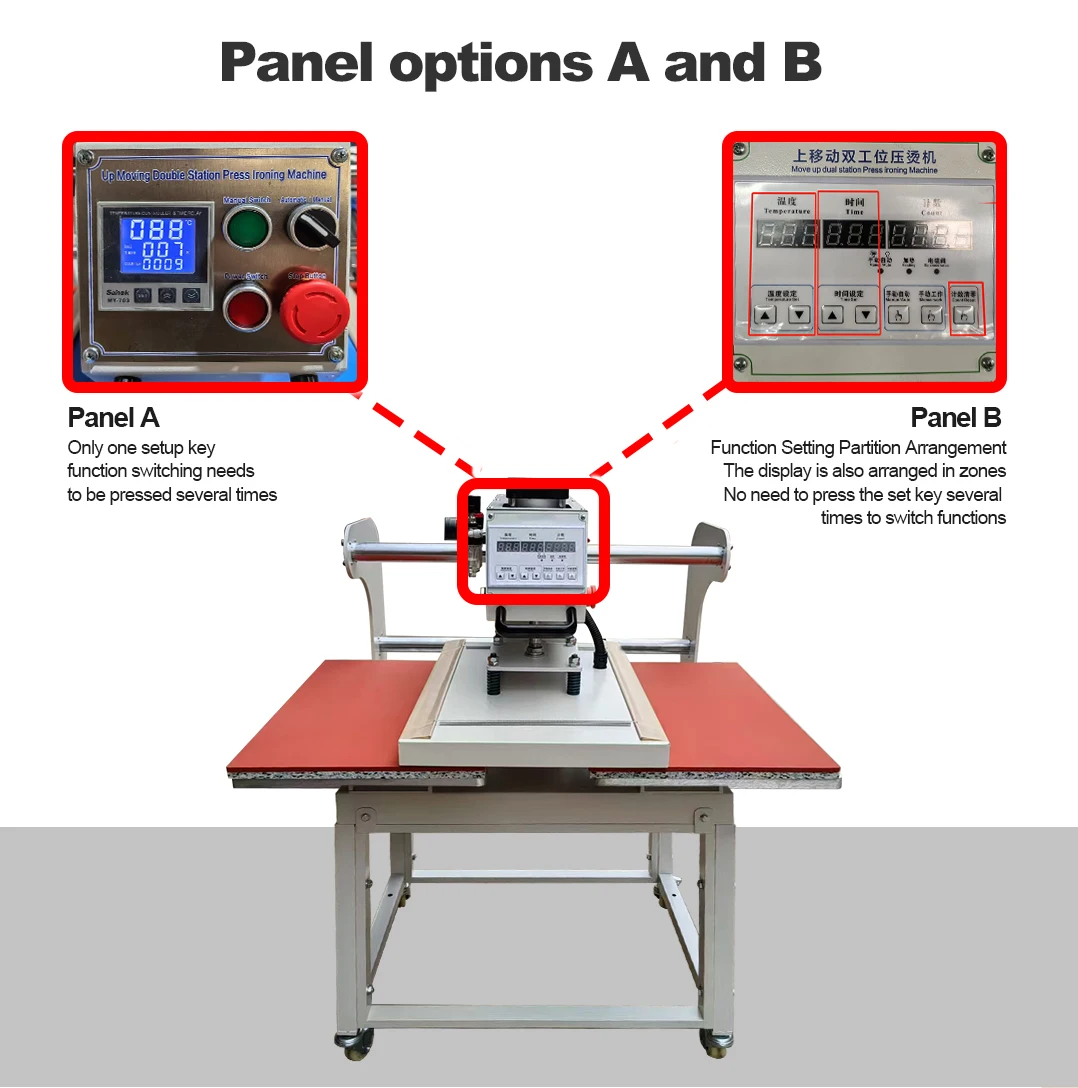

MOMOTECH brand’s dual-station heat press machines are highly regarded in the market for their diverse functionality and wide range of applications. The brand offers four different types of heat press machines to meet various user needs: 1. Pneumatic Fully Automatic Dual-Station Heat Press Machine:

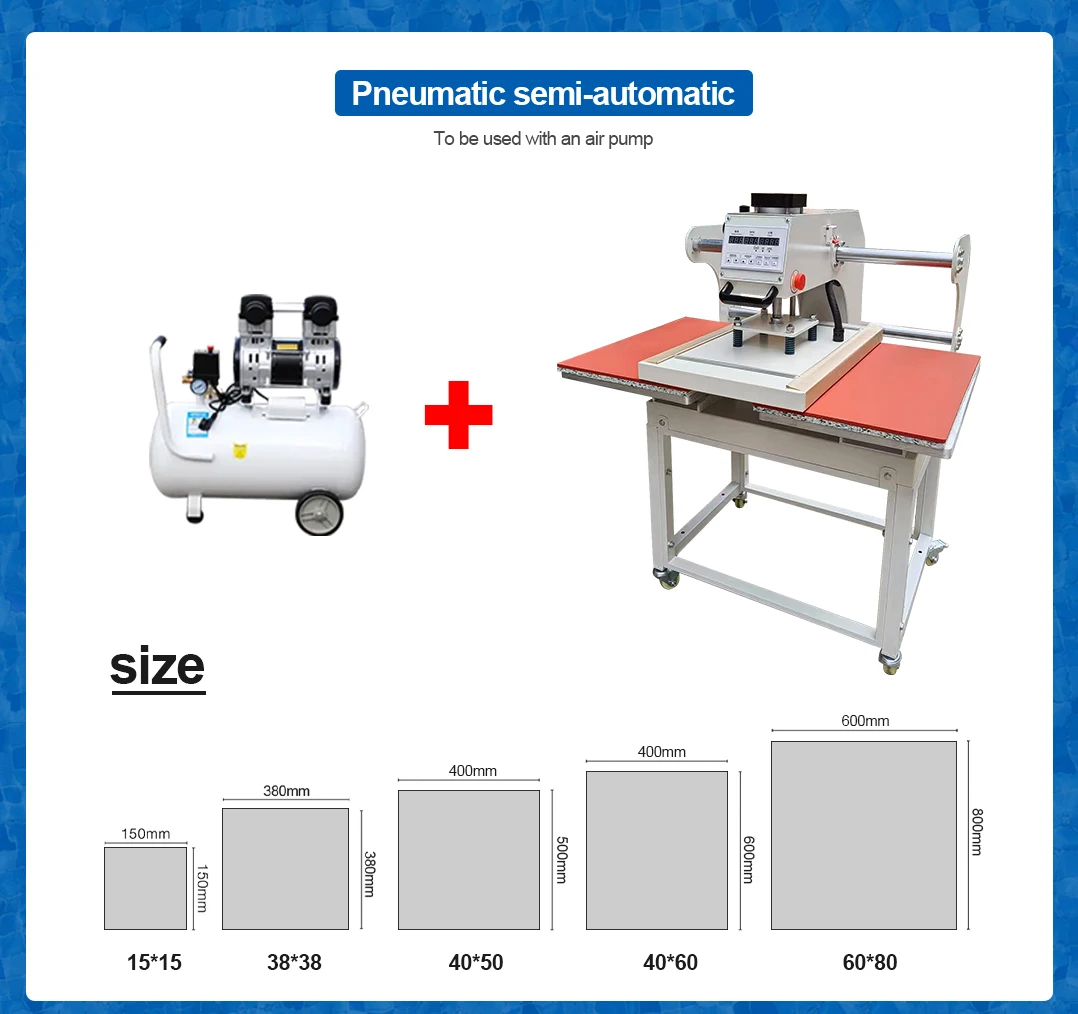

This model features fully automatic control, capable of automatic movement and pressing, greatly saving labor and improving work efficiency. 2.Pneumatic Semi-Automatic Dual-Station Heat Press Machine:

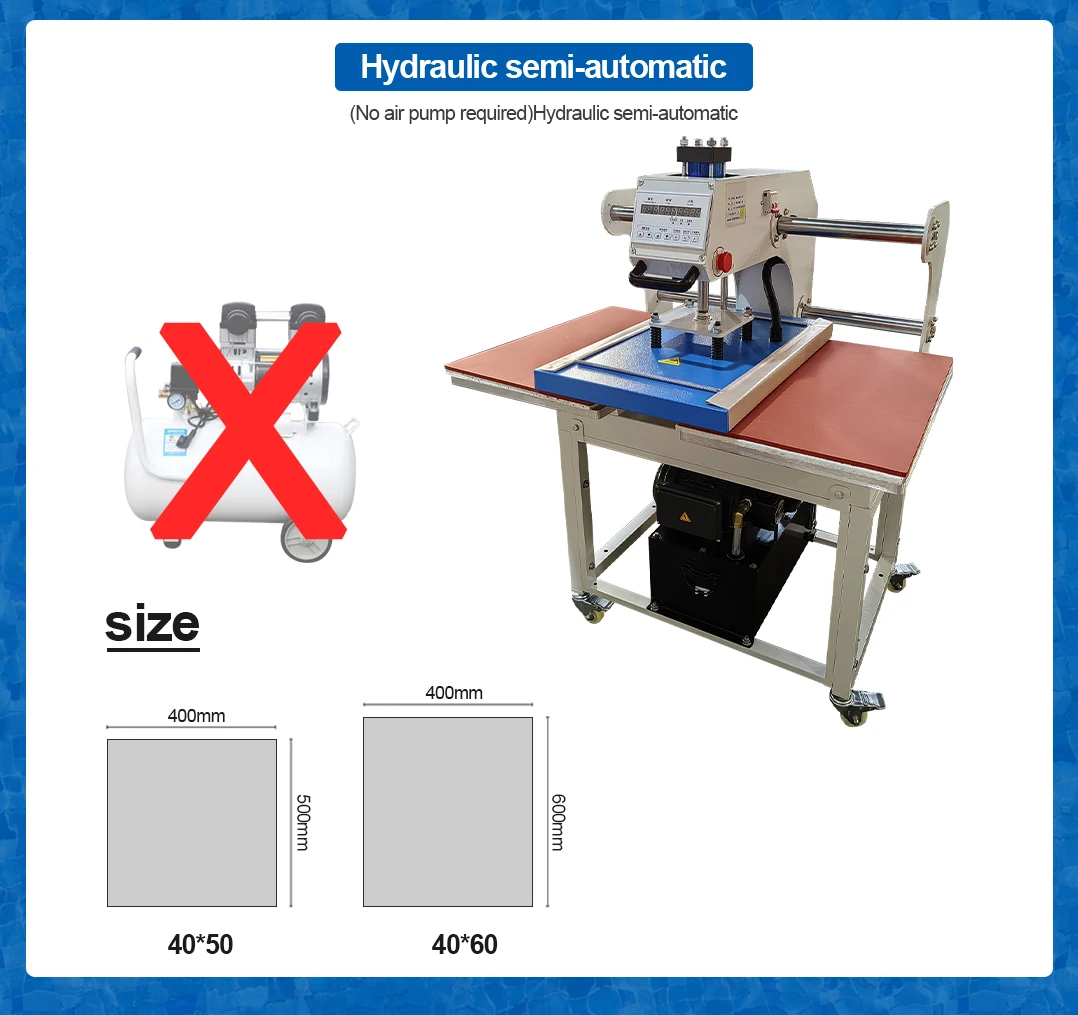

Driven by air, it is easy to operate with a dual working surface design that increases work efficiency, suitable for pressing trademarks and small area heat transfers. 3. Hydraulic Semi-Automatic Dual-Station Heat Press Machine:

Equipped with advanced linear bearing sliding operation, it is simple and convenient, with a heat plate that moves to switch positions, preventing garment movement, and pressure up to 30kg/cm². 4. Electronic Fully Automatic Dual-Station Heat Press Machine:

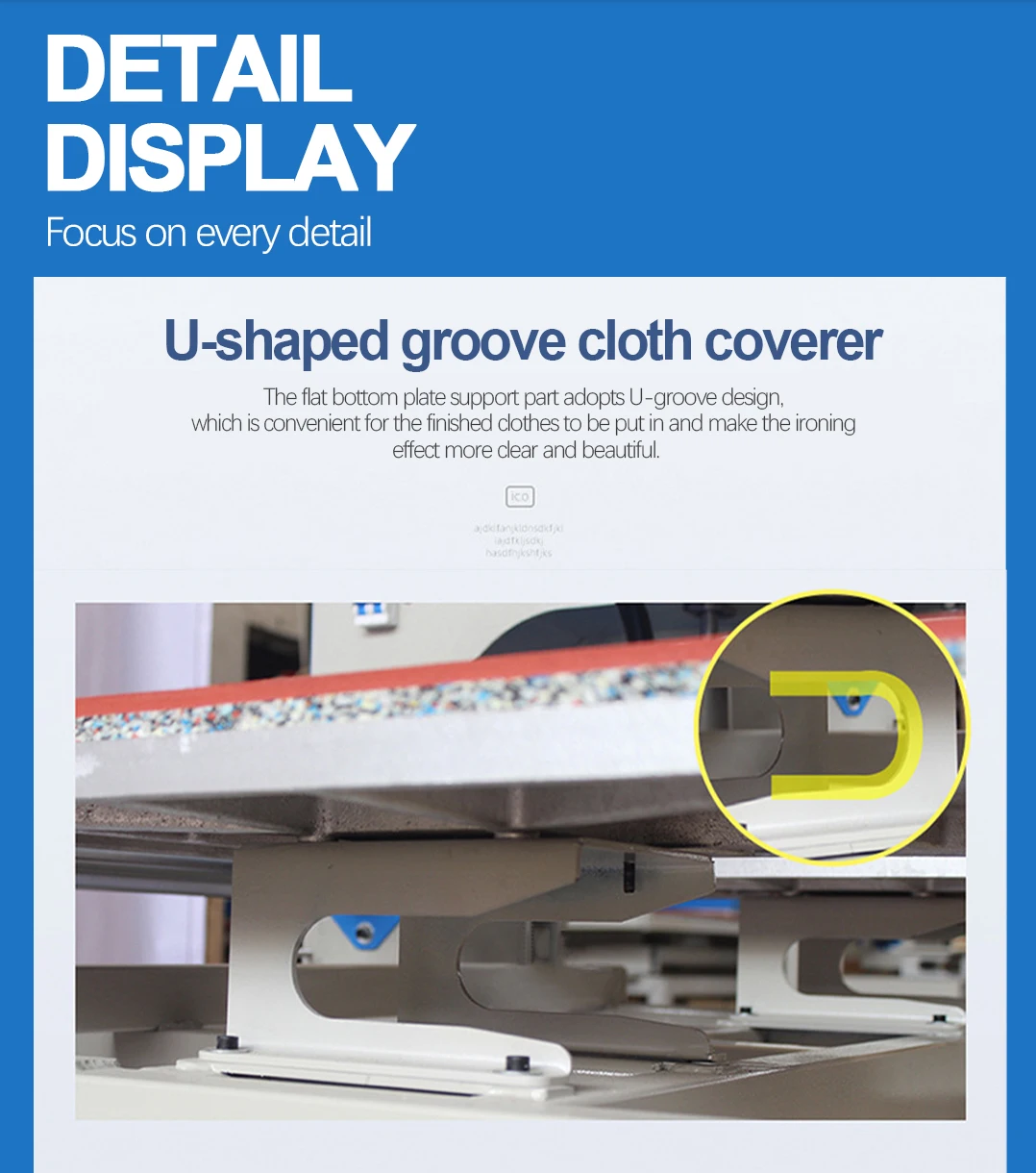

Controlled by PLC touch screen technology, it offers precise positioning and stable performance, with fully automatic control as a standout feature, smooth and fast movement, saving labor, and improving work efficiency. Additionally, MOMOTECH dual-station heat press machines come in a variety of heat transfer area specifications to accommodate different sizes of heat transfers, including: – 15cm x 15cm – 38cm x 38cm – 40cm x 50cm – 40cm x 60cm – 60cm x 80cm These specifications make MOMOTECH dual-station heat press machines widely applicable in garment factories and special transfer materials, especially suitable for cultural T-shirt and other clothing transfers, economical, practical, and with exquisite patterns.

|

Serial No.

|

Product

Type

|

Printing

Size

(CM)

|

Package size

(CM)

|

Weight

(KG)

|

Temp.Range

(℃)

|

|

1

|

Pneumatic

Semi-automatic |

15*15cm

|

76*60*70

|

61

|

0-399

|

|

2

|

Pneumatic Semi-automatic

|

38*38cm

|

120*95*85

|

145

|

0-399

|

|

3

|

Pneumatic Semi-automatic

|

40*50cm

|

125*95*85

|

153

|

0-399

|

|

4

|

Pneumatic Semi-automatic

|

60*80cm

|

170*105*890

|

215

|

0-399

|

|

5

|

Pneumatic

Full automatic

|

15*15cm

|

76*60*70

|

63

|

0-399

|

|

6

|

Pneumatic Full automatic

|

40*50cm

|

125*95*85

|

155

|

0-399

|

|

7

|

Pneumatic Full automatic

|

40*60cm

|

125*95*85

|

160

|

0-399

|

|

8

|

Pneumatic Full automatic

|

60*80cm

|

170*105*890

|

220

|

0-399

|

|

9

|

Hydraulic

Semi-automatic

|

38*38cm

|

125*85*85

|

260

|

0-399

|

|

10

|

Hydraulic Semi-automatic

|

40*50cm

|

125*85*85

|

270

|

0-399

|

|

11

|

Hydraulic Semi-automatic

|

40*60cm

|

125*95*85

|

280

|

0-399

|

|

12 |

40*50cm |

110*83*87

|

140

|

0-399

|

Pneumatic / Hydraulic / Electronic

Dual-Station Heat Press Machine

Semi-automatic & Fully automatic

1. Material Bonding:

Pneumatic heat press machines bond materials through heat and pressure, commonly used in industries like printing, textiles, and manufacturing. 2. Printing Industry:

In printing, automatic heat press machines imprint logos, designs, or text on items such as t-shirts, bags, and hats. 3. Manufacturing:

Heat press machines are also employed in manufacturing to bond layers of materials using heat and pressure.

Classification and Application Fields of Heat Press Machines

A heat press machine is a device that uses heat transfer technology to transfer designs or patterns onto various materials. It is widely used in the apparel, home furnishings, and electronics industries. Based on different classification criteria, heat press machines can be divided into various types, each with its unique application scenarios and advantages.

Classification by Platen Shape and Function

1,Flatbed Heat Press Machine Features: The platen is flat, suitable for fabrics such as clothing and apparel, and can be used to transfer prints onto T-shirts, sweatshirts, and sportswear. Application Fields: Mainly used for custom clothing and advertising promotions. Examples of Actual Products: Custom T-shirts: Transferring personalized patterns or text onto T-shirts to meet consumers’ demand for unique clothing. Sportswear: Adding brand logos or sponsor advertisements to sportswear.

2,Mug Heat Press Machine Features: The platen is cylindrical, specifically designed for printing on mugs. Application Fields: Suitable for creating personalized mugs, such as ceramic or porcelain mugs. Examples of Actual Products: Ceramic Mugs: Transferring decorative patterns or photos onto ceramic mugs to create unique gifts. Porcelain Mugs: Adding landscape patterns or portraits to porcelain mugs.

3,Cap Heat Press Machine Features: The platen has a curved shape, specifically designed for finished hats. Application Fields: Used for creating hats with patterns or logos, such as baseball caps and visors. Examples of Actual Products: Baseball Caps: Adding brand logos or creative designs to baseball caps. Visors: Customizing visors with unique patterns to meet fashion needs.

4,Plate Heat Press Machine Features: The platen is flat, suitable for hard surfaces such as ceramics and metals. Application Fields: Used for transferring prints onto plates, tiles, and other hard materials. Examples of Actual Products: Ceramic Plates: Transferring colorful patterns onto ceramic plates. Tiles: Adding decorative patterns to tiles for home decoration.

5,Phone Case Sublimation Heat Press Machine

Features: Specifically designed for sublimation printing on phone cases, allowing for the customization of unique patterns. Application Fields: Used for creating personalized phone cases to meet consumers’ demand for unique electronic accessories. Examples of Actual Products: iPhone Cases: Transferring photos or creative designs onto iPhone cases. Glass Phone Cases: Adding transparent patterns to glass phone cases.

Features: Specifically designed for sublimation printing on phone cases, allowing for the customization of unique patterns. Application Fields: Used for creating personalized phone cases to meet consumers’ demand for unique electronic accessories. Examples of Actual Products: iPhone Cases: Transferring photos or creative designs onto iPhone cases. Glass Phone Cases: Adding transparent patterns to glass phone cases.

Classification by Operating Power

1,Manual Heat Press Machine Features: Requires manual operation, with lower costs, suitable for small-scale production. Application Fields: Suitable for small studios or individual users. Examples of Actual Products: Small Studio: Used for creating a small number of custom clothing or souvenirs.

2,Pneumatic Heat Press Machine Features: Uses a pneumatic cylinder to apply pressure, making operation effortless and speeding up the printing process. Application Fields: Suitable for scenarios requiring fast printing, such as T-shirts and cultural shirts. Examples of Actual Products: Cultural Shirts: Quickly transferring prints onto cultural shirts for batch production.

3,Hydraulic Heat Press Machine Features: Uses hydraulic drive, providing high and even pressure, suitable for large-area printing. Application Fields: Suitable for printing on large billboards and sheet transfers. Examples of Actual Products: Large Billboards: Transferring high-definition patterns onto large billboards.

Classification by Operating Method

1,Manual Heat Press Machine Features: Requires manual operation, suitable for small-scale production. Application Fields: Suitable for small studios or individual users. Examples of Actual Products: Handicraft Enthusiasts: Used for creating personalized T-shirts or mugs.

2,Semi-Automatic Heat Press Machine Features: Partially automated operations, such as automatic timing and alarms, suitable for medium-scale production. Application Fields: Suitable for studios with a certain production scale. Examples of Actual Products: Medium Studio: Used for batch production of custom clothing.

3,Automatic Heat Press Machine Features: The entire printing process is automated, suitable for large-scale production. Application Fields: Suitable for large garment factories or commercial gift-making enterprises. Examples of Actual Products: Large Garment Factory: Used for mass production of custom T-shirts.

Application Fields of Heat Press Machines

1,Apparel Industry Application: Heat press machines play an important role in custom clothing, quickly transferring design drafts or personalized patterns onto fabrics to improve production efficiency. Market Share: Accounts for about 70% of the heat press machine application market. Examples of Actual Products: Custom T-shirts: Transferring personalized patterns or text onto T-shirts. Sportswear: Adding brand logos to sportswear.

2,Home Furnishings Application: Used for transferring prints onto bedding, curtains, and other items to meet the demand for personalized home decoration. Market Share: Accounts for about 15% of the market share. Examples of Actual Products: Bedding: Transferring landscape patterns onto bed sheets and pillowcases. Curtains: Adding unique patterns to curtains.

3,Electronics Enclosures Application: Used for customizing the exteriors of electronic products such as phone cases and headphone covers. Examples of Actual Products: Phone Cases: Transferring photos or creative designs onto phone cases. Headphone Covers: Adding brand logos to headphone covers.

4,Stationery and Other Fields Application: Used for transferring prints onto stationery, keychains, and other small items to meet diverse market demands. Examples of Actual Products: Stationery: Adding unique patterns to the covers of notebooks. Keychains: Adding brand logos to keychains. Heat press machines, with their flexible pattern design and production capabilities, meet consumers’ demand for personalized products and are widely used in the apparel, home furnishings, and electronics industries. When selecting a heat press machine, it is necessary to consider factors such as production scale, transfer materials, pattern complexity, and working environment to choose the most suitable equipment.

Reviews

There are no reviews yet.