Details Images

Continuous Innovation, High Quality INDUSTRIAL 3D PRINTER

The MD-600 Pro/Pro+ is an easy-to-use, large-format 3D printer specially designed for industrial applications using engineering-grade materials. With a sleek, space-conscious body, perfect for the production of quality parts in any setting, the MD-600 Pro is optimal for any workspace, from the office to the factory floor. Whether it’s factory tooling, prototypes, or end-use parts, the MD-600 Pro is a durable and cost-effective way to manufacture large-format, quality parts.

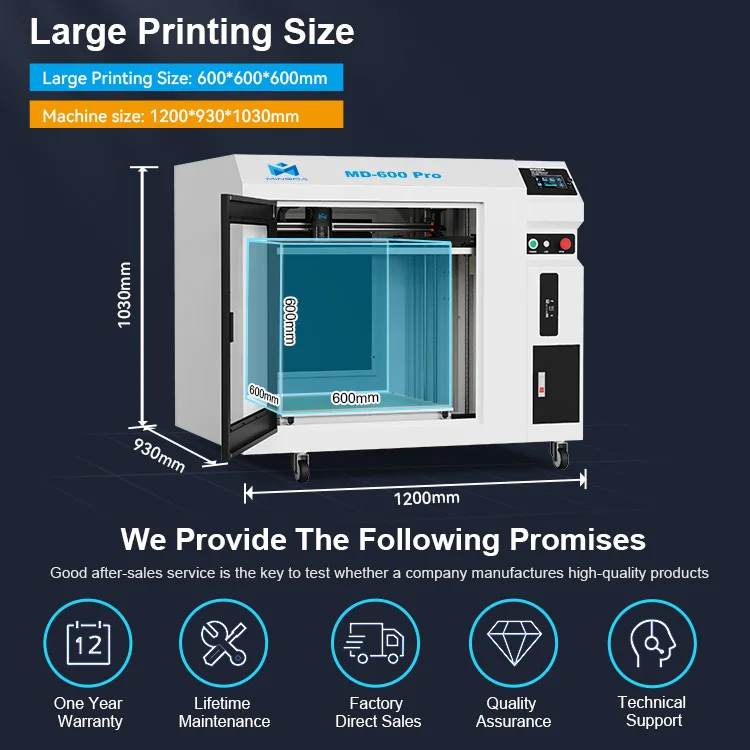

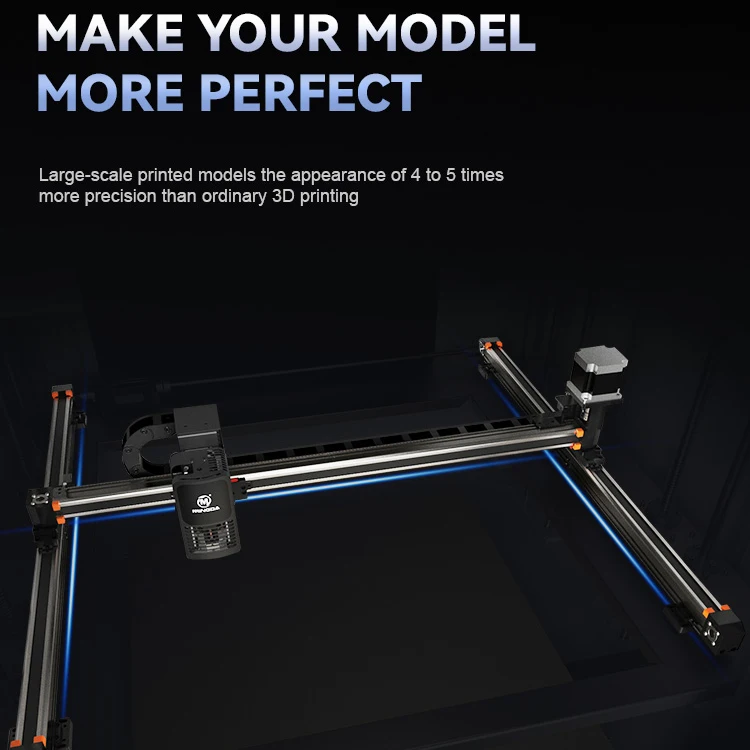

The MD-600 Pro/Pro+ boasts a generous build volume of 600 * 600 * 600 mm, 10 times that of standard desktop 3D printers. Featuring a fully enclosed build envelope and temperature-controlled filament chamber, the fast-heating MD-600 Pro produces incredible results with advanced materials. Its high-flow MD-600 Pro+ Dual Extruder (SDX) is equipped with two 0.6 mm nozzles optimal for printing geometrically complex parts with ASA, ABS, water-soluble support, and abrasive materials like carbon-fiber-reinforced

plastic quickly and reliably.

plastic quickly and reliably.

Product Parameters

|

Printing

|

||||

|

Model Name

|

||||

|

Build Volume

|

600x600x600mm

|

|||

|

Weight

|

N.W.380KG/ G.W. 480KG

|

|||

|

Print Technology

|

Fused Deposition Modeling

|

|||

|

Number of Nozzle

|

Single

|

|||

|

Layer Resolution

|

0.05 mm-0.3mm

|

|||

|

Filament Diameter

|

1.75 mm

|

|||

|

Filament Compatibility

|

PLA、ABS、ASA、TPU、PETG、PETG-ESD,PP, PET-GF, PET-CF, PA12-CF,HtPA-GF, HtPA-CF,Nylon,Carbon Fiber Etc.

|

|||

|

Nozzle Diameter

|

0.4mm ( 0.6, 0.8, 1.0mm)

|

|||

|

Sample

|

||||

|

Temperature

|

||||

|

Max. Nozzle Temp.

|

450℃

|

|||

|

Max. Bed Temp.

|

110℃

|

|||

|

Speed

|

||||

|

Best Printing Speed

|

60-100mm/s

|

150-200mm/s

|

||

|

Max Printing Speed

|

200mm/s

|

200mm/s+

|

||

|

Platform

|

10mm thickness aluminum hot bed

|

|||

|

Levelling

|

Auto Leveling and Babystep

|

|||

|

Eletrical

|

||||

|

Power Requirements

|

110V/220V |

|||

|

Max. Power

|

780W

|

|||

|

Screen

|

5.0 inch Color Touch Screen

|

|||

|

Connectivity

|

USB,SD card

|

|||

|

Software

|

||||

|

Uninterruptible Power System

|

Save data when power is off

|

|||

|

Filament Detection

|

Pause printing when filament run out

|

|||

|

Automatic Shutdown

|

Turn off the power automatically when printing is complete

|

|||

Application Situation

PROTOTYPES

● Produce full-scale, functional parts from the alpha phase to zero series

● Learn faster and iterate designs in hours and days, not weeks and months

● Avoid expensive, outsourced, and traditional slow production

● Learn faster and iterate designs in hours and days, not weeks and months

● Avoid expensive, outsourced, and traditional slow production

TOOLING, JIGS, FIXTURES

● Customize tools for perfect fit, reduced weight, and ergonomic design

● Slash lead times with on-demand production and avoid outsourcing logistics

● Reduce production and material costs of optimized tooling

PATTERNS AND MOLDS

● Replace high-cost patterns and molds made from expensive materials

● Speed up design iteration, product testing, and production

● Minimize outsourcing, external logistics, and supply chain dependence

END-USE PARTS

● From small-series production to unique parts without added costs

● Produce on-demand to reduce inventory and warehousing

● Reduce lead times and get to market fast to stay ahead of the competition

Online&Offline Technical Training

We have a complete online and offline training system. The training content includes software and equipment training. When your goods arrive at your home, we will have technical contacts with you.If you want to know more,Send inquiry at the upper right !

Reviews

There are no reviews yet.