LONES MACHINERY was established in 2014. It is a professional manufacturer and exporter

specializing in the design, manufacture and sales of semi automatic pet blow molding machine, full automatic pet bottle making machine and pet bottle molds; and provides PET One-stop solutions for a series of products such as PET preform moulds and plastic cap molds; in order to meet the needs of customers in different countries and regions, we continue to update processing equipment,improve processing accuracy and optimize machine design; the factory runs synchronously with production and management, greatly Improves the timeliness of manufacturing equipment; all our equipment meets international quality standards and is greatly appreciated all over the world.

|

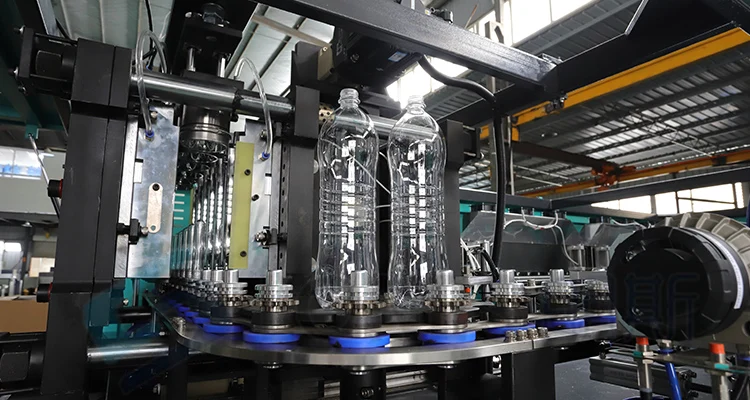

LS-A6 FULL AUTOMATIC water bottle BLOW MOULDING MACHINE

|

||||||

|

THEORETICAL OUTPUT

|

6500-8500BPH for 500ml bottle

|

|||||

|

MAX. CONTAINER VOLUME

|

2L

|

|||||

|

MAX.NECK DIAMETER

|

45MM

|

|||||

|

MAX.CONTAINER DIAMETER

|

100MM

|

|||||

|

MAX.CONTAINER HEIGHT

|

340MM

|

|||||

|

NUMBER OF CAVITY

|

6CAVITY

|

|||||

|

TOTAL POWER

|

55KW

|

|||||

|

USE POWER

|

40KW

|

|||||

|

WORKING PRESSURE

|

1.0MPA

|

|||||

|

LOW PRESSURE CONSUMING

|

1600L/MIN

|

|||||

|

BLOWING PRESSURE

|

≤3.5MPA

|

|||||

|

HIGH PRESSURE CONSUMING

|

3600L/MIN

|

|||||

|

MACHINE WEIGHT

|

5500KGS

|

|||||

|

Actual output depends on bottle shape and preform quality.

Above technical parameters are subject to continual update,please take the real machine as the base. |

||||||

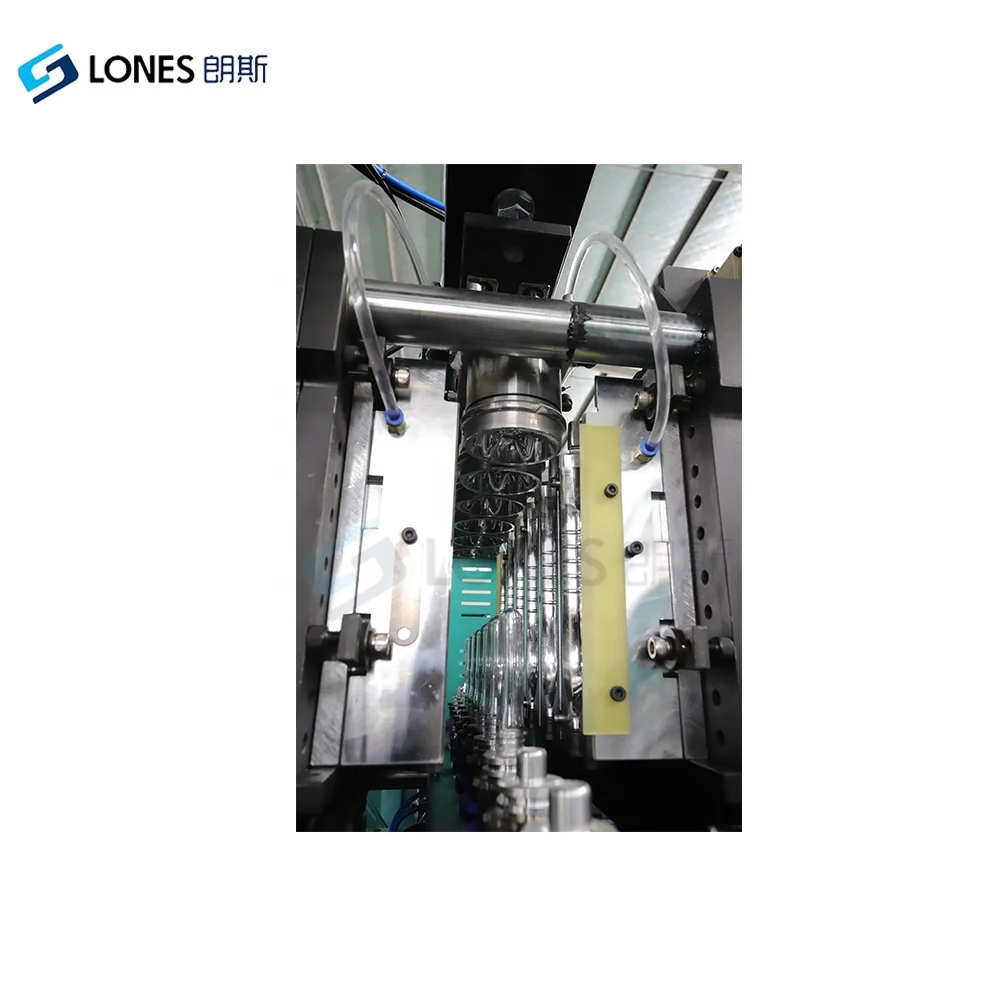

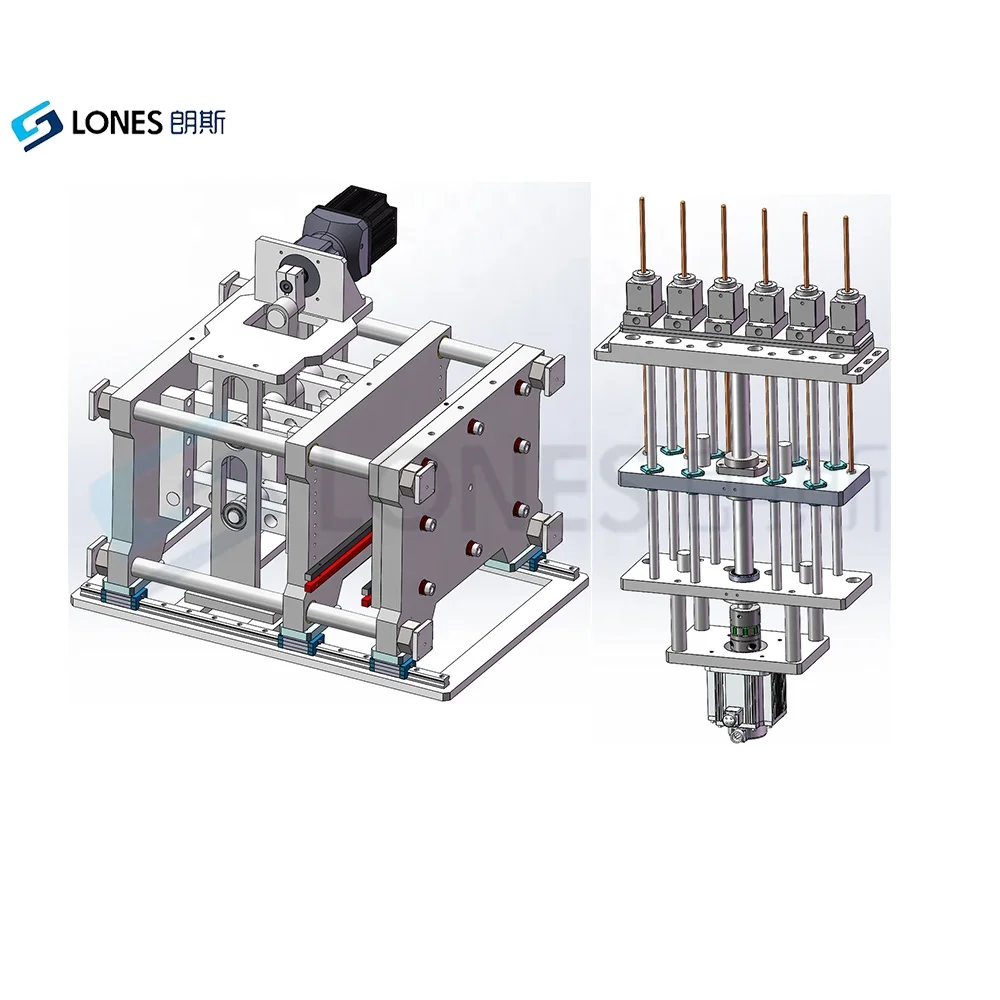

Main Features for 6cavity full automatic blow moulding machine

1.The preform is automatic loaded,the formed bottle is automatically unbottled,without manual taking bottle.

2.The variable distance transmission design and single group circulation heating system make the preform heating center distance smaller, heating efficiency faster, and saving more than 30% energy.

3. Modular design saves space and effectively reduces maintenance and parts replacement costs.

4. The machine is equipped with automatic alarm (show the cause of the alarm) and intelligent protection devices to easy maintenance and ensure safe operation.

5. High pressure mold clamping and blowing system with low vibration and noise.

6.Can be directly connected to the filling line to avoid secondary contamination of bottles and save labor.

7. Special blowing 100ML to 2000ML water, carbonated, juice, milk, Sparkling water, oil bottles, alcoholic beverages, detergent bottles, cosmetic bottles, medicine bottles

Reviews

There are no reviews yet.