Introduction

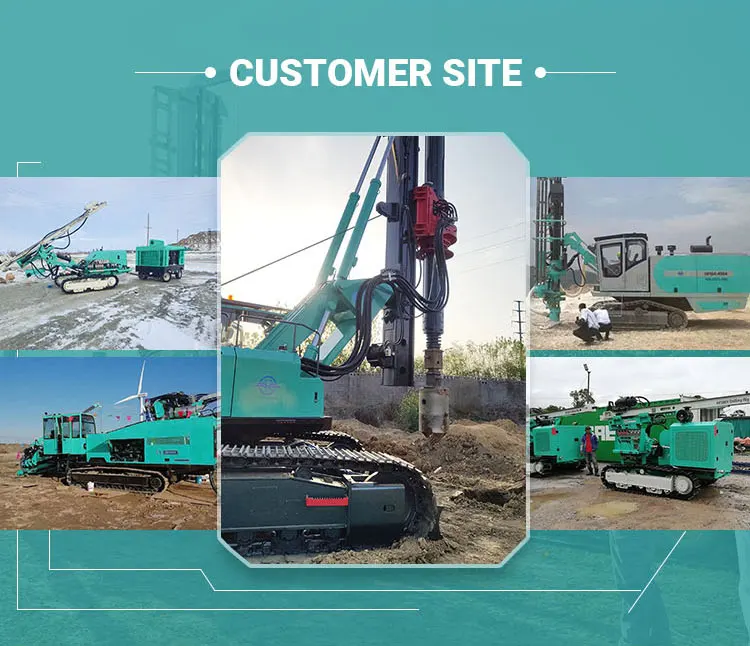

different specifications of drilling tools, pile hole diameter ranges 500-1500mm.

It has high drilling efficiency, and after construction, it can quickly move to next working site. It is flexible, convenient and

efficient, a national high-speed rail construction-specific piling machinery equipment.

This machine is applicable to soil, clay, fill soil, silt, silt layer, and some strata contain pebbles, gravel, widely used in

high-speed rail trestle piles, slop shield piles, photovoltaic power station foundation pile, power grids, civil construction, new

rural construction, municipal construction, landscaping and other projects.

Features:

Flexible: the whole tonnage is small, simple operating, moving fast, convenient transition, etc.

High returns: small investment, quick gains, economic advantages can not be replaced. Technology patents: patent uses a unique

technology to achieve a small torque but big power characteristics, thus achieve a small machine to drill big piling hole.

|

model

|

HF340

|

|

Drilling diameter

|

1600mm

|

|

drilling depth

|

40m

|

|

Diamension

|

14.3 m*3.8m*3.8m

|

|

Total weight

|

41T

|

|

Power head max output torque

|

150KN.m

|

|

Rotary speed

|

5-30RPM

|

|

Pressurized oil cylinder max pressure

|

150KN

|

|

Pressurized oil cylinder max lifting force

|

150KN

|

|

Main winch max lifting force

|

160KN

|

|

Main winch max lifting speed

|

64m/min

|

|

Assisting winch max lifting force

|

50KN

|

|

Assiting winch max lifting speed

|

60m/min

|

|

Pressurized oil cylinder max stroke

|

3500mm

|

|

Maximum grade

|

15 °

|

|

System pressure

|

32Mpa

|

|

Travelling speed

|

3km/h

|

|

Working Radius

|

4.8 m

|

|

Diesel engine power

|

170KW, Cummins

|

|

Torque

|

150KN·m

|

We are a professional manufacturer. Our factory mainly produces water well drilling rigs, core drilling rigs, down-the-hole drilling rigs, pile drivers, etc. The products have been exported to hundreds of countries around the world and enjoy a high reputation all over the world.

2. How is the quality of your machine?

Our products pass strict quality inspections before they leave the factory to ensure that they are qualified before they are shipped.

3. How to inspect the goods?

1) Support customers to come to the factory for on-site inspection.

2) Support customers to designate third-party companies to inspect goods.

3) Support video inspection.

4. Do you have after-sales service?

Yes, we have a dedicated service team that will provide you with professional technical guidance. If you need, we can send our engineers to your workplace and provide training for your employees.

5. How about quality assurance?

We provide a one-year quality guarantee for the main machine of the machine.

6. How long is your delivery cycle?

1) In the case of stock, we can deliver the machine within 7 days.

2) Under standard production, we can deliver the machine within 15-20 days.

3) In the case of customization, we can deliver the machine within 20-25 days.

Reviews

There are no reviews yet.