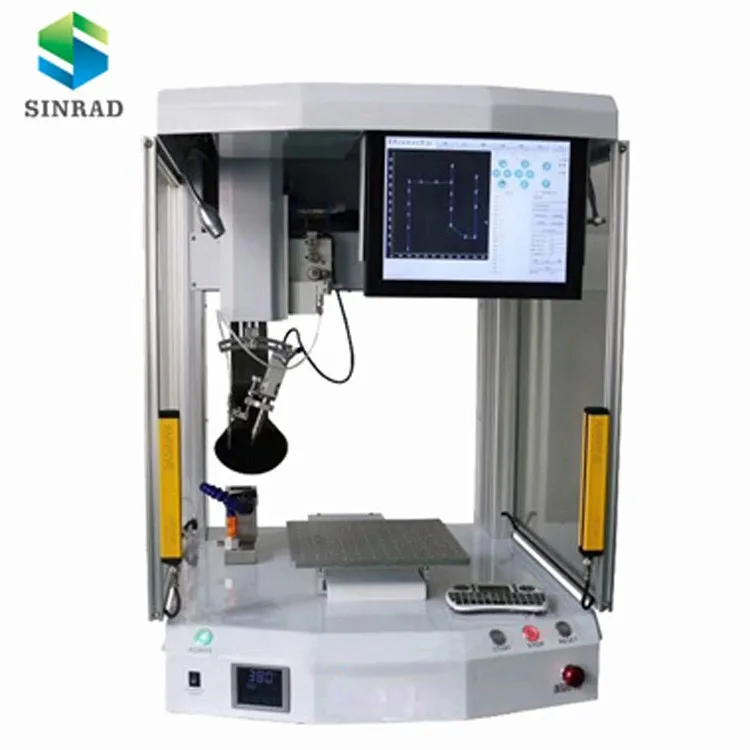

5 axis Desktop Soldering Robot Product Application

Smd Soldering Machine provides the best solution for soldering job on lead-free, heat dissipating PCB, and high thermal capacity components. It is suitable for all sorts of difficult soldering tasks and micro soldering process. It effectively improves the soldering quality and consistency. Besides, it saves 30% of the solder consumption comparing to manual soldering

|

SPECIFICATIONS FOR 5 axis Desktop Soldering Robot

|

||

|

Technical Index

|

Tech-Parameters

|

|

|

axle

|

5 axle+ tin solder

|

|

|

trace (X*Y*Z*R)mm

|

500*350*100*360°

|

|

|

Operate speed (X/Y/Z/R)

|

X/Y/Z:800mm/s R:180°/s

|

|

|

station

|

single station

|

|

|

Repeat Accuracy

|

±0.02mm

|

|

|

loading weight

|

10Kg

|

|

|

Program recording capability

|

unlimited

|

|

|

display

|

12'' display screen

|

|

|

operate mold

|

touch screen+ remote

|

|

|

motor

|

stepper

|

|

|

termperature

|

100℃~480℃

|

|

|

Heating mode

|

high frequency induction

|

|

|

min tin length

|

0.01mm

|

|

|

Solder Wire Dia

|

0.3~1.6mm

|

|

|

Voltage

|

220V AC/50HZ

|

|

|

air pressure

|

0.4~0.8MPa, clean and dry

|

|

|

environment

|

0~40℃, humidity 20%~95%

|

|

|

weight

|

110kg

|

|

|

size

|

(W*D*H)600*580*850mm

|

|

5 axis Desktop Soldering Robot Main Function

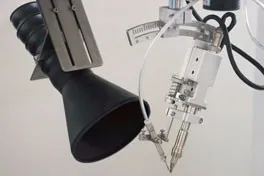

1. The fourth generation welding head with precision cylinder and rail buffer and angle adjustment structure

2. The base of the machine is made of sheet metal and CNC machined to ensure the precision and consistency of the parts. It also ensures the stability of the machine operation.

3. The tin-broken system equipped on the soldering machine itself can prevent the tin slag from exploding when the machine is in operation.

4. The X, Y and Z axes of the fuselage adopt double guide structure to improve the stability of the soldering machine operation

5. Digitize the program, modify the parameters directly, change the same tin spot once, insert and delete one click

6. Unlimited procedural recording capabilities

7. Touch screen + wireless remote control teach pendant operation

8. The controller adopts man-machine interaction, good data processing capability, powerful network communication functions, and IPC that can execute relatively complicated control algorithms and its near-unlimited storage capacity.

9. CCD positioning device with high speed and high separation rate to effectively improve the positioning accuracy of the moving end (customized according to customer requirements)

10. Unique fast and high precision temperature control technology based on power compensation, soldering power 400w/600W (optional)

11. Machines can connect to soldering machine inspection cloud-based, like fault pre-warning, and diagnostics intelligent after-sales service cloud platform

12. Robot with blow-type tip cleaning box

13. 12-inch high-definition touch screen man-machine interface, trajectory display, soldering process is more intuitive

14. Optional pneumatic soldering capability

15. With anti-collision function, it can reduce the damage rate of accidental collision of the soldering machine

16. Multi-user authority management mode to prevent operators from changing parameters by mistake

17. The machine integrates ERP and MES system communication and downloads the program from a specific server automatically. The acquisition of equipment status, the uploading of production data and the equipment parameters can all be invoked via ERP and MES (optional).

18. Support to install bar code scanning code

19. The width of the assembly line is freely adjustable, suitable for most of product soldering.

20. Intelligent smoke purification filter device to ensure the cleanliness and safety of the production environment

21. The system display language is Chinese, English and Japanese

22. The temperature sensor uses a thermal resistor to increase the accuracy of temperature data acquisition. Its applicable range is -199°C to 649°C.

23. 400W/600W high-frequency eddy current silver wire heating wire heater

24. Number of soldering iron setting and soldering times setting, automatic alarm setting; Sn/tin-plating automatic alarm setting.

5 axis Desktop Soldering Robot machine Feature.

1.Wireless remote control, easy to edit soldering program

2.12-inch high-definition touch screen man-machine interface, trajectory display,soldering process is more intuitive

3. The fourth generation welding head with precision cylinder and rail buffer and angle

4.Unique fast and high precision temperature control technology based on power compensation, soldering power 400w/600W (optional)

Machine Parts

Name:Iron Parts

Brand: SINRAD

Original: CHINA

・Easy to maintenance (soldering tip, heater)

・Shock absorbing mechanism

・Press-down soldering is possible

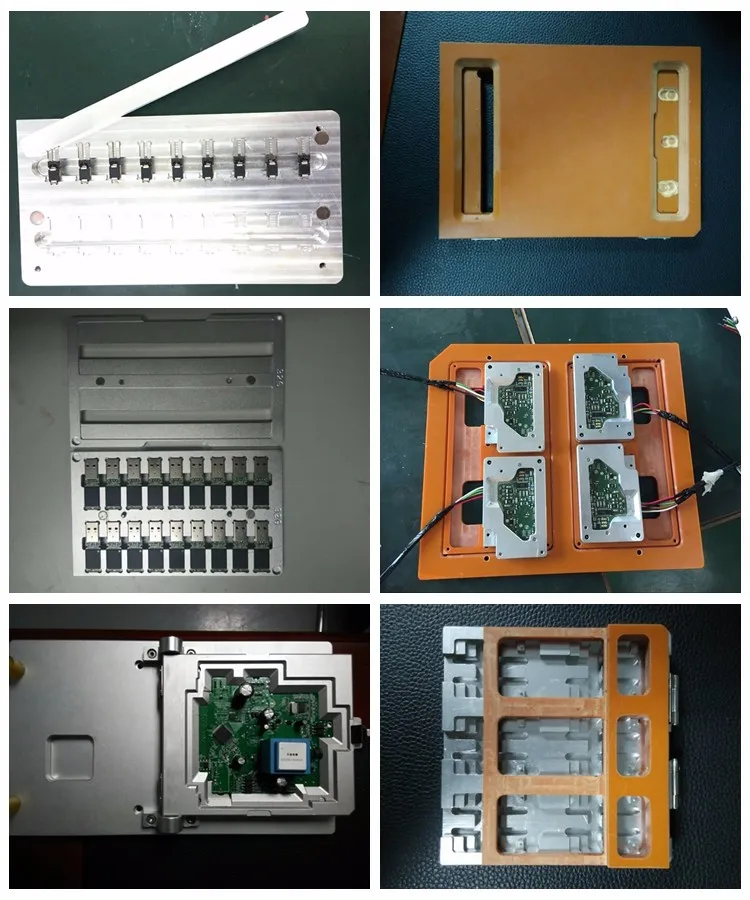

Machine Parts

Name: Tin feeding System

Brand: SINRAD

Original: CHINA

・Supports φ0.6-1.2mm (φ0.3, 0.4 , 1.6mm for optional)

・Shortage & jam alarm

Machine Parts

Name: Fixture

Brand: SINRAD

Original: CHINA

・Customized base on different product

Main Features

Name: 12'' TOUCH SCREEN

Brand: SINRAD

Original: CHINA

・12'' display screen

・Touch screen

|

Packaging

|

||

|

Size

|

(D) 700mm*900mm*1050mm

|

|

|

Weight

|

140kg

|

|

|

Packaging Details

|

The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Reviews

There are no reviews yet.