Machine Structure and Parameters

The cup filling machine is a fully automatic packaging equipment designed for cup products. Its working principle mainly includes the following steps:

1.Automatic cup loading and dropping: The equipment automatically places the empty cup in the designated position to prepare for subsequent filling. 2.Precise filling: Through the automatic control system, the specific volume of materials (such as ketchup, mayonnaise, etc.) is accurately measured and poured into the cup. The filling process is fast and stable. 3.Automatic coding and sealing: After filling, the equipment automatically codes to identify product information. Subsequently, the product is sealed through automatic film placement, sealing and other steps. 4.Automatic cup removal and cup delivery: Finally, the equipment automatically removes the packaged product from the filling line and delivers it to the designated area for subsequent packaging or transportation. The entire filling process does not require human participation, which greatly improves production efficiency and corporate economic benefits.

|

Machine Model

|

KL-160YB

|

||||||

|

Machine name

|

Automatic Rotary Cup BBQ Sauce Butter Cup Filling Packing Machine

|

||||||

|

Filling speed

|

1 cup per 1 cup, 700 cups/hour

|

||||||

|

Filling accuracy

|

10-200ml (can be more) Depend On Your demand

|

||||||

|

Cover material

|

PP

|

||||||

|

Metering Accuracy

|

±0.5g (depending on the material)

|

||||||

|

Working air pressure

|

0.6-0.8Mpa

|

||||||

|

Power

|

2.5KW

|

||||||

|

Power supply specifications

|

220V, 50Hz (support customization)

|

||||||

|

Machine weight

|

400kg

|

||||||

|

Machine Size

|

1100*1100*1700mm

|

||||||

|

Suitable for packaging products

|

Chili sauce, ketchup, juice, jelly, sauce, liquid, hand soap, shampoo, cooking oil, lotion, cream, etc.

|

||||||

|

Additional configuration

|

Coding printer/Gas-filled device/Bag conecting device/Punch device/Easy to tear gap device

|

||||||

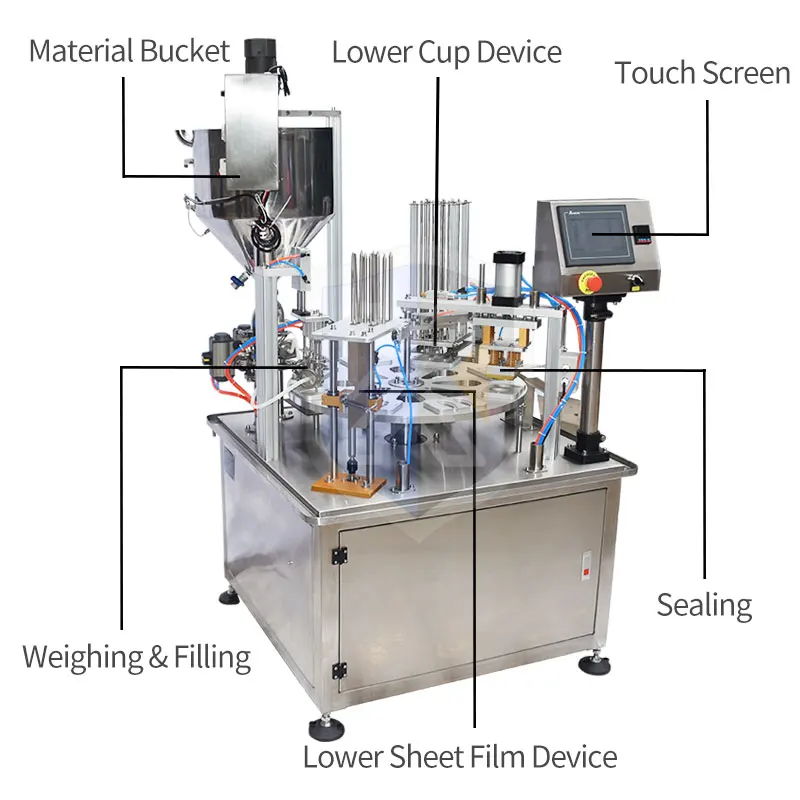

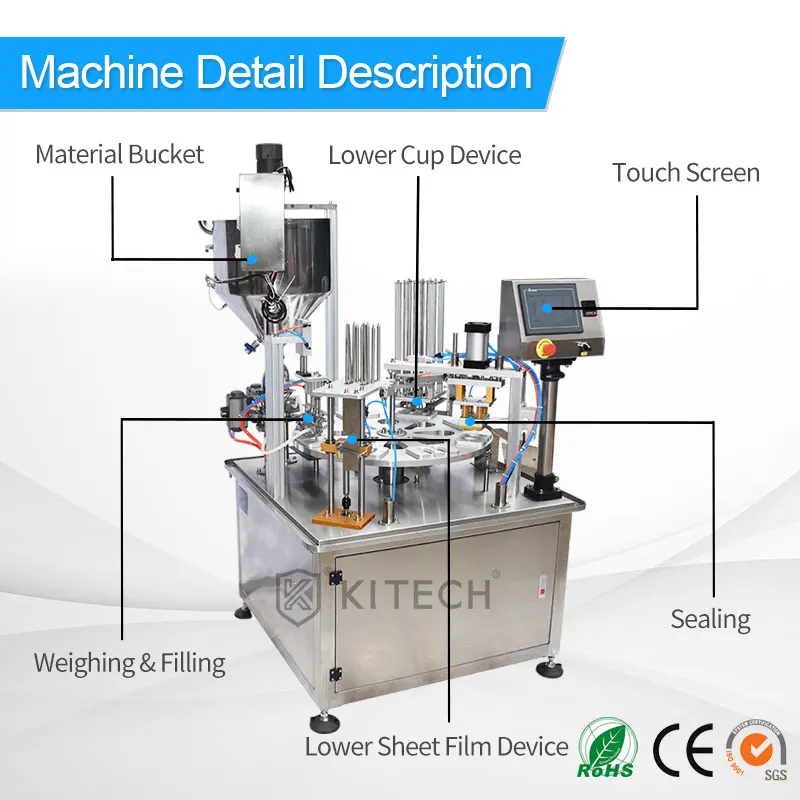

Machine Details

Multilingual Touch Screen

Multi-language touch screen can switch various languages at the same time, and when there is a problem with the machine, it will automatically alarm, pause the operation and show where the machine is in the problem.

Pneumatic pump metering device

Kitech exclusive patented technology device, using new custom pneumatic pump weighing, when the packaging weight is not accurate will automatically adjust to reach the preset weight, no manual operation to adjust, saving time and cost.

Cup Hole Device

Different mold shapes can be customized according to the shape of your cup/spoon. One machine supports 1-2 mold shape replacements..

Servo Control System

Servo control system is used on machine weighing device, film pulling device, bag making and sealing. When there is a problem in one part, the machine will automatically stop running and alarm to remind the operator to check, therefore, one person can operate 15 machines at the same time to save cost.

Free Accessories

Application Products

Bag Type

Optional Device

Reviews

There are no reviews yet.