Product Description

Hot selling multifunctional automatic egg tray making machine quail egg carton machine with drying oven

The automatic egg tray machine is used to produce paper egg tray. The main working process of paper egg tray machine is composed of pulping system, forming system and drying system. Paper tray making machine is mixing the waste paper and water. When it reaches the certain concentration, the egg tray pulp can be conveyed to forming machine. The whole production line include pulp making system, moulding system, drying system and packaging system.

And it is also a waste recycling machine, the raw material use general waste paper, like old book, old newspaper ,abandoned carton and so on. There are various types and output of egg tray making machines can be supplied by our company ,such as 1000pcs per hour ,2000pcs per hour,2500pcs,3000pcs per hour ,3500pcs,4000pcs per hour ,and so on .You only can tell me what capaicty machine do you want,our professional engineer will design the most suitable machine for you!

Technical Parameters

|

Machine Model

|

FY-3*1

|

FY-4*1

|

FY-3*4

|

FY-4*4

|

FY-4*8

|

FY-5*8

|

FY-5*12

|

|

Capacity (pcs/h)

|

1000

|

1500

|

2000

|

2500

|

3000

|

5000

|

6000

|

|

Total Power (KW)

|

32

|

45

|

58

|

78

|

80

|

85

|

90

|

|

Paper Consumption (kg/h)

|

120

|

160

|

200

|

280

|

320

|

400

|

480

|

|

Water Consumption (kg/h)

|

300

|

380

|

450

|

560

|

650

|

750

|

900

|

|

Workshop Area (sq.m.)

|

45

|

45

|

80

|

80

|

100

|

100

|

120

|

Note:

1.More plates ,more less water use

2.Power means the main parts,not include dryer line

3.All fuel use proportion are calculated by 60%

4.single dryer line length 42-45 meters,double layer 22-25 meters, multi layer can save worshop area.

2.Power means the main parts,not include dryer line

3.All fuel use proportion are calculated by 60%

4.single dryer line length 42-45 meters,double layer 22-25 meters, multi layer can save worshop area.

Production process

Detail images

Advantage:

1. Raw material: Any kind of waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get

2. Automation: Fully-automatic control

3. Quality standard: CE

4. 100% environmentally production process.

5. Engineers available to service machinery overseas.

Related Products

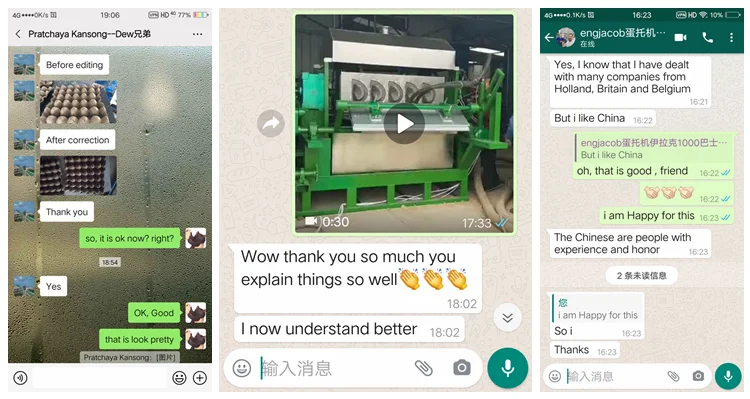

Our Service

Pre-sales

1. Online all day, to ensure that all your questions are answered within two hours.

2. Give you professional advice and recommend the machine that suits you.

3. Arrange the time and invite you to visit our factory.

On-sales

1. One Stop Service

2. customized service

All machines can be customized, like color, embossing, jumbo roll core diameter.

All machines can be customized, like color, embossing, jumbo roll core diameter.

After-sales

1. One year warranty, we provide free machine parts within one year.

2. Any question you can tell us if you have when operate the machine.

2. Any question you can tell us if you have when operate the machine.

Packing and Delivery

Packaging:

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.

3. Wrapped with tight plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Shipment:

1.Sea transportation is from Qingdao port or other ports.

2.The delivery time is decided by your needed machines or machine parts. But it also follows your needs.

Why Choose Us

Henan Fuyuan Machinery Manufacturing Co., Ltd located in Zhengzhou City, Henan Province.Our factory is founded in 1984 with rich experience in paper making machine and egg tray making machinery. Our main products include: Egg Tray Machine,Facial Tissue Machine,Napkin Paper Machine,Toilet Paper Rewinding Machine, Kraft paper machine,Cultural Paper Machine and other Paper Processing Machinery. After 36 years of development, our company has developed into a large enterprise integrating scientific research, production and trading,our factory covers an area more than 33,000 square meters, construction area more than 16,000 square meters, existing staff more than 200 workers, including 5 senior engineers, 22 engineers, and more than 38 technical staff. We are committed to provide customers with a complete solution for paper making project and paper egg tray making production line,welcome the friends to visit us over the world.

FAQ

Q1: How long does it take to produce and install equipment?

A: Production time: 15-25 working days, depending on the model, or customers need to customize the mold, there may be a big difference

Installation time: no drying: 25-30 days, drying with 30-40 days

Q2: How much space is required for production?

A: Please kindly confirm the machine model you need, for the model confirming, I need to know what is the production capacity do you want, 1000 pcs per hour, 2000 pcs per hour, 3000-5000 pcs per hour or other requirement. After confirming the machine model, the area space will be sent to you accordingly.

Q3: What is the additives to combine those materials?

A: Paper and cartons are good material for producing egg tray ,no need to add other additives. The pulp is combined by paper and water.

Q4: How to operate and maintain the machine?

A: First, we will provide a professional and detailed user guide to you with the machine; Second, we will debug the machine in the best status for you; At last, we also provide abroad technical training service.

Q5: Which kind of product can this machine make?

A: The machine can product the egg trays egg box, egg carton,fruit tray and wine tray and so on. If you want to produce other paper industrial packages, we can customize the mould per your requirement.

Q6: What voltage the machine can work normally ?

A: The machines can adapt the voltage 220v/380v.

Reviews

There are no reviews yet.