|

DW-3040

|

DW-3040

|

|

Laser tube

|

40W (50W/60W option)

|

|

Engraving speed

|

0-50mm/s

|

|

Cutting speed

|

0-30mm/s

|

|

Minimum character

|

Letter 1.0 x 1.0mm

|

|

Resolution ratio

|

0.005mm

|

|

Voltage

|

110V±10%/ 220V±10% ,50HZ ~60HZ

|

|

Cutting thickness

|

Depends on your materials

|

|

Laser tube’s life

|

5000 hours

|

|

Support graphic format

|

JPG, PNG, BMP, PLT, DST, DXF, CDR, AI, DSB, GIF, MNG, TIF, TGA, PCX, JP2, JPC, PGX, RAS, PNM, SKA, RAW , etc.

|

|

Display

|

LCD monitor system

|

|

Packing size

|

93*78*59cm

|

|

Processing area

|

300*400mm

|

|

Control system

|

CorelDraw

|

|

Scanning Precision

|

2500DPI

|

|

Rotary platform

|

Option

|

Hot Selling DIY Stamp Maker with 300*400MM Working Size Rubber Stamp Making Machine.

2)Adopt high-precision guide rails imported from South Korea.Improve laser engraving and cutting accuracy and ensure that the laser machine runs efficiently and stably for a long time.

3)5mm thick aluminum alloy oxidation work platform, to ensure the level of the work platform, improve the accuracy of object carving.

4)High precision drive motor.The X / Y axis uses a high-precision belt-driven Leadshine motor to improve response speed and cutting engraving accuracy. More accurate than the unknown brand motors used by other manufacturers, and longer working life.

5)The latest manual rotary lifting system is fast and stable. Engraving materials of different thicknesses, the height of the working platform can be adjusted freely. With the focal length ruler on the right side of the machine’s working platform, the focus can be quickly determined without measuring the distance from the laser head to the material with a manual ruler.

6) Adopt the new high-efficiency CO2 laser tube of TONGLI, the 40W co2 laser tube can reach a peak of 50W. The laser beam is more stable and the life of the laser tube can exceed 7,000 hours.

7) Red dot positioning Synchronize with the laser, which make the operation more convenient.

8) Coreldarew or Ruida system can ensure the engraving cutting task completed quickly at one time.

Hot Selling Rubber Stamp Making Machine 300*400MM Working Size to Make Self Inking Rubber Stamp.

(1) Cutting:

acrylic,perspex,wood,MDF,plywood,veneer,paper,leather,rubber,fabric,cloth,canvas,foil,leather,fur,foam,plastic,PES,PC,PA,PE,PP,composite material,PVC, etc.

(2) Engraving:

acrylic,perspex,wood,MDF,plywood,stone,marble,glass,jade,crystal,metalcoating,paper,leather,rubber,fabric, cloth,plastic,PVC,etc.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

2.After-Sales Service:

*Within 7 days since your local customs clearance:if the machine has any problems,we will change it free.

*Exceed 7 days since your local customs clearance but within warranty period if the machine parts have any problems,we can change the old machine parts to new ones free,but you should pay all the shipping cost.

*Exceed one year warranty period if the machine parts have any problems,we can offer new machine parts with cost price and you also should pay all the shipping cost.

*We offer 24 hours technical support by call,email.

*Our technician can give you remote guide online(Skype/MSN/What’s app/viber/Tel/Etc) if you have any question.

*Machine has been adjusted before delivery,operation disk is included in the delivery.If there is any other questions,pls kindly tell me.

*We have manual instruction and CD (Guiding Videos) for software Installation,operation and machine’s using and maintenance.

3.Dowin Tech Co.,Ltd supply free technical training for all customers all over the world until the workers from buyer can operate the machine normally and individually. Mainly training are as follow:

*Training for Control software operation.

*Training for normatively turning on/off operation of the machine.

*Instruction of technical parameters, as well as their setting ranges.

*Basic daily cleaning and maintenance for the machine.

*Solutions for common hardware problems.

*Training for other questions and technical suggestions during daily production.

4.Training can be processed in the following ways:

*Workers of customers can come to our factory get the most professional hand-by-hand training.

*We can send engineers to customers’ country and do training for workers in customers’ target factory.However,tickets and daily consumption like food and accommodation should be afforded by customers.

*Remote training through Internet tools like Team-viewer,Skype and other instant communication softwares.

Focus on researching and manufacturing of laser machine for over 11 years.

A: No, the laser machines we provide are capable of both engraving and cutting. One machine alone can fulfill the two purposes.

Q: How to distinguish laser tubes with different powers and applications?

1. Laser tube length (relatively speaking, the longer, the bigger)

2. Laser tube diameter (relatively speaking, the thicker, the bigger)

3. The bigger a laser tube power is, the deeper the machine can cut, but its light spot is bigger. So, it is better to use a machine with a low-power laser tube to engrave, such as 40W,50W , 60W or 80W.

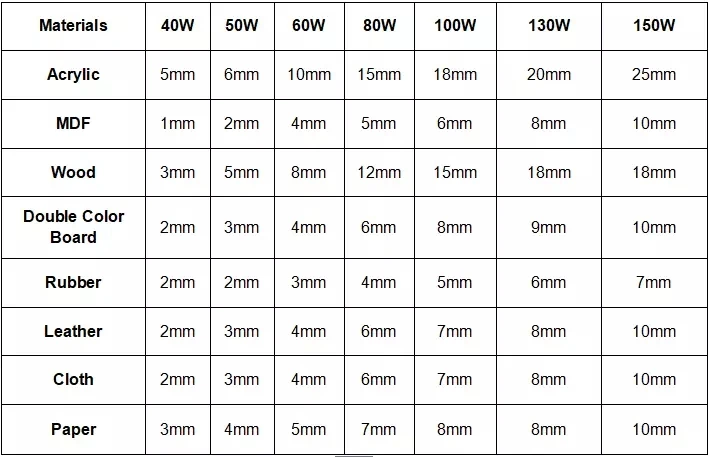

40W laser tube 5mm Acrylic

50W laser tube 6mm Acrylic

60W laser tube 10mm Acrylic

80W laser tube 15mm Acrylic

100W laser tube 18mm Acrylic

130W laser tube 20mm Acrylic

150W laser tube 25mm Acrylic

We have also document telling what cutting /engraving speed for different materials.

A: Generally, a laser tube’s service life can reach 5000 hours to 10000 hours depending on the specific usage. For example, if it works 8 hours per day, the detailed data is as follows:

1. If you set the power at 20-30% of the total power, the service life is about 1-2 years.

2. If you set the power at 40-50% of the total power, the service life is about 1 year.

3. If you set the power at 70-80% of the total power, the service life is about 6-8 months.

Q: How can I tell the power of a laser tube has been exhausted?

A: The beam color of a new laser tube in operation is purple. When the power is gradually depleted, the color will become white.

A: If you are able to use some basic graphic design software, it will only take a few hours to master the operation. You just need to do some simple tests on different processing materials to know how to set the correct speed and laser power.

A: It is not harmful as long as the laser is not exposed directly to skin and eyes.

The machine has one year guarantee. If it breaks down, generally speaking, our technician will figure out what the problem may be, according to client s feedback. Parts except for consumable parts will be replaced for free, if the problems are caused by quality problem under “normal use”.

Western Union(WU),Telegraphic Transfer(T/T) to our official company bank account or pay Via alibbaba trade assurance order. For standard machines, it would be 3-5days; For non-standard machines and customized machines according to client’s specific requirements, it would be 7-15 days.

Reviews

There are no reviews yet.