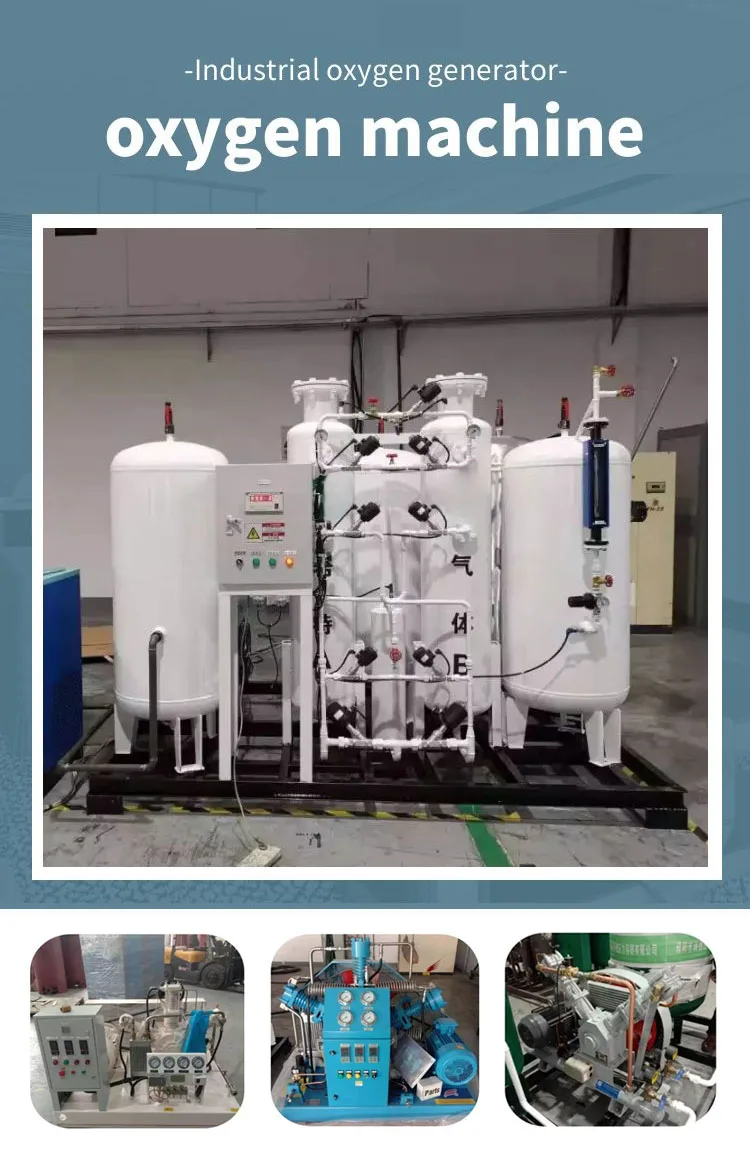

Hospital Containerized medical psa oxygen generator PSA oxigen plant Medical Oxygen Production Plant

Products Description

Industrial oxygen generators are favored by users with their obvious advantages, and are widely used in metallurgical combustion, chemical industry, environmental protection, building materials, light industry, medical treatment, aquaculture, biotechnology,

sewage treatment and other fields.

sewage treatment and other fields.

Pressure Swing Absorption oxygen production equipment, referred to as PSA oxygen production equipment, is a new gas separation technology. Taking adsorbent molecular sieve as an example, its principle is to use molecular sieve to “adsorb” different gas

molecules. Separate the gas mixture. It uses air as raw material, and uses a high-efficiency, high-selectivity solid adsorbent to selectively adsorb nitrogen and oxygen to separate nitrogen and oxygen in the air. Zeolite molecular sieves selectively adsorb molecules based on the size of the pores inside their crystals, that is, adsorb molecules of a certain size and repel molecules of larger substances. In this way, oxygen-rich components can be obtained in the gas phase. After a period of time, the adsorption of

nitrogen by the molecular sieve reaches equilibrium. According to the different characteristics of the adsorption capacity of the zeolite molecular sieve under different pressures, the pressure is reduced to release the adsorption of nitrogen by the zeolite

molecular sieve. This process is called regeneration. The pressure swing adsorption method usually uses two towers in parallel, alternately performing pressure adsorption and decompression regeneration, so as to obtain a continuous oxygen flow.

molecules. Separate the gas mixture. It uses air as raw material, and uses a high-efficiency, high-selectivity solid adsorbent to selectively adsorb nitrogen and oxygen to separate nitrogen and oxygen in the air. Zeolite molecular sieves selectively adsorb molecules based on the size of the pores inside their crystals, that is, adsorb molecules of a certain size and repel molecules of larger substances. In this way, oxygen-rich components can be obtained in the gas phase. After a period of time, the adsorption of

nitrogen by the molecular sieve reaches equilibrium. According to the different characteristics of the adsorption capacity of the zeolite molecular sieve under different pressures, the pressure is reduced to release the adsorption of nitrogen by the zeolite

molecular sieve. This process is called regeneration. The pressure swing adsorption method usually uses two towers in parallel, alternately performing pressure adsorption and decompression regeneration, so as to obtain a continuous oxygen flow.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

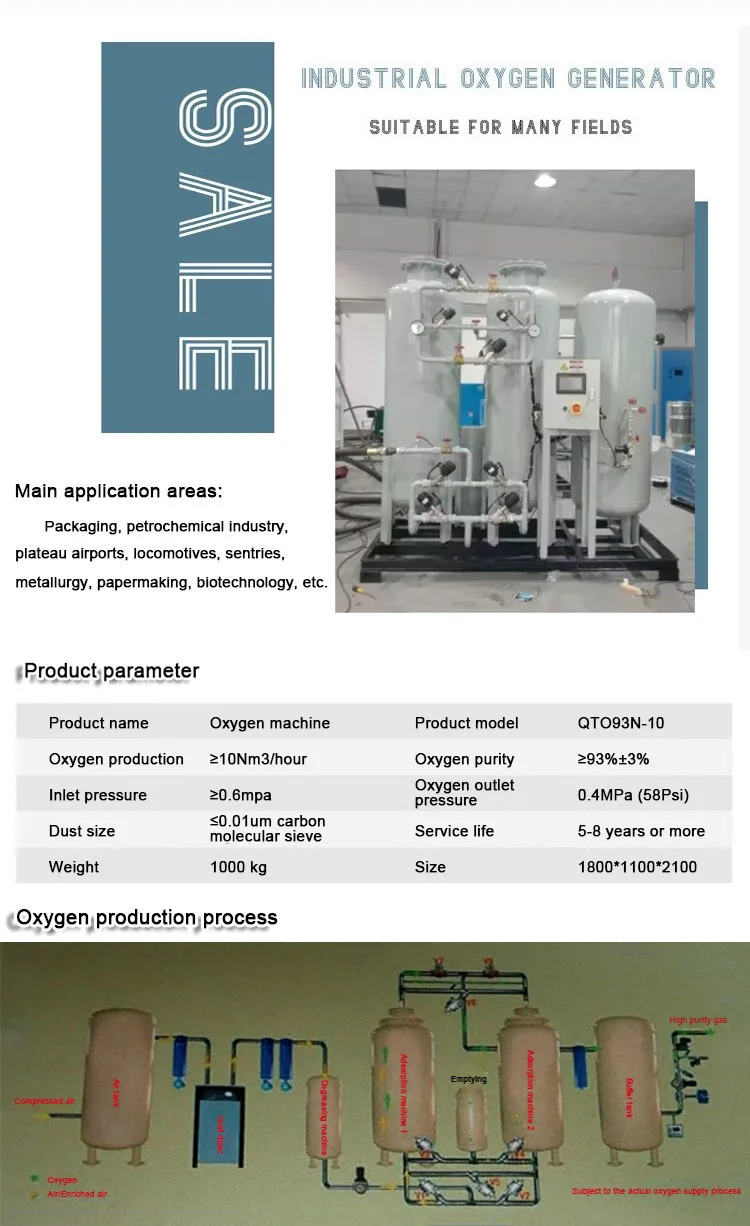

Product Paramenters

|

Oxygen production:

|

≥10Nm3/h

|

|

Oxygen purity:

|

≥93%±3%

|

|

Inlet pressure:

|

≥0.6mpa

|

|

Oxygen outlet pressure:

|

0.4MPa (58Psi)

|

|

Dust particle size:

|

≤0.01um carbon molecular sieve

|

|

Service life

|

more than 5-8 years

|

|

Weight:

|

1000KG

|

|

Size:

|

1800*1100*2100

|

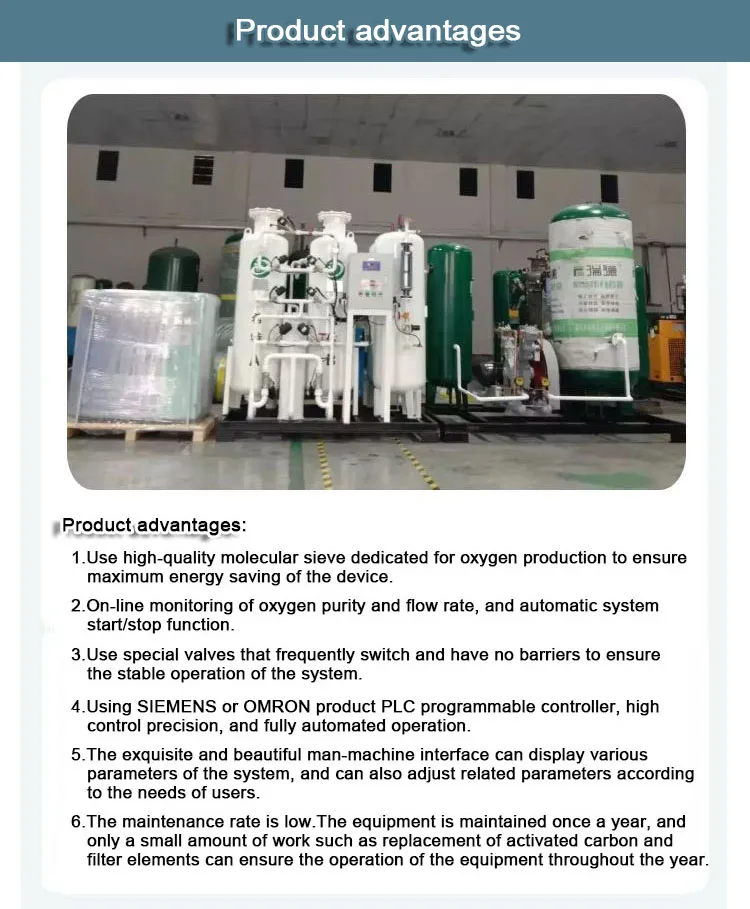

Feature

The pressure swing adsorption industrial oxygen generator is an automatic equipment that uses zeolite molecular sieve as the

adsorbent, and uses the principle of pressure adsorption and decompression desorption to adsorb and release nitrogen from the air,

thereby separating oxygen. Zeolite molecular sieve is processed by a special pore type treatment process. The spherical particle

adsorbent with micropores on the surface and inside is white. Its pore type characteristics enable it to realize the kinetic

separation of 02 and N2. The separation effect of zeolite molecular sieve on 02 and N2 is based on the slight difference in the

dynamic diameter of the two gases. N2 molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and O2

molecules have a slow diffusion rate. The diffusion of water and CO2 in compressed air is not much different from that of

nitrogen. The final enrichment from the adsorption tower is oxygen molecules.

Company Profile

Why Choose Us

1. Because we are a professional humidifier manufacturer, and the products are high-quality and safe, we hope to establish a long-term and stable relationship with our customers.

2. More favorable prices, so that customers can buy with confidence

3. Fast delivery

4. Provide customers with better solutions to save costs

5. Professional service, ready for customers

2. More favorable prices, so that customers can buy with confidence

3. Fast delivery

4. Provide customers with better solutions to save costs

5. Professional service, ready for customers

Product packaging

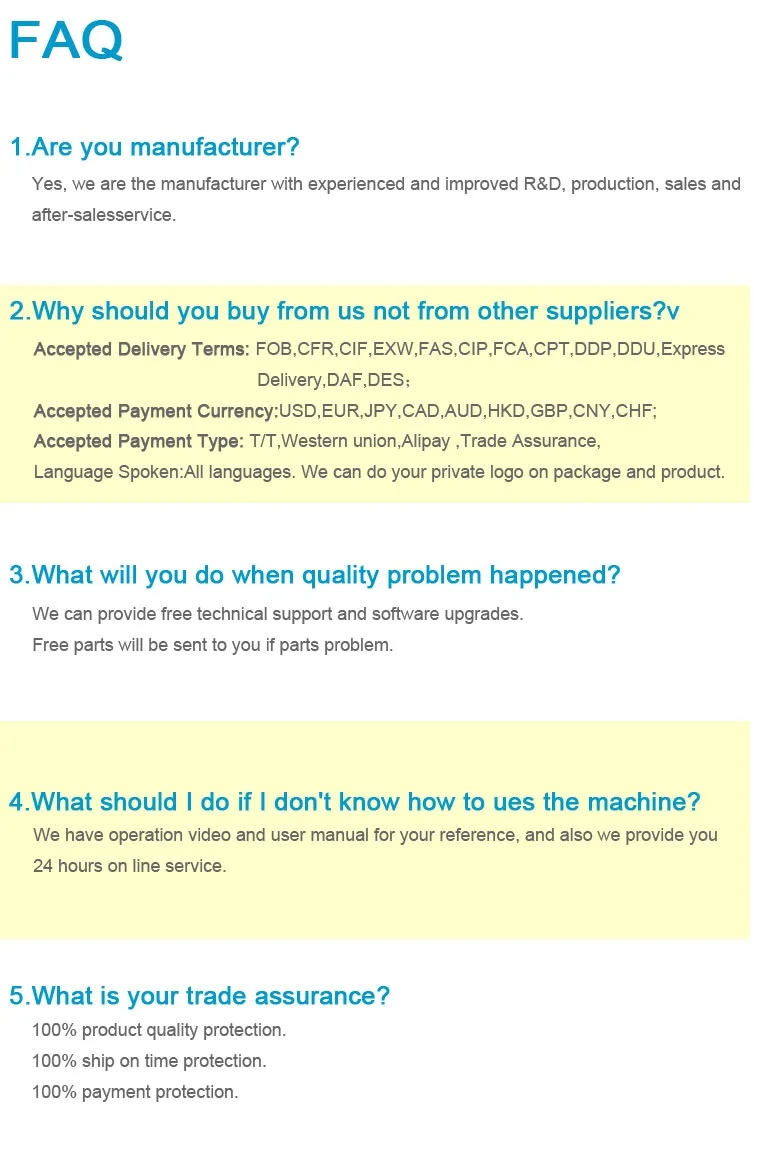

FAQ

Certifications

Contact us

Instock, discount, more new arrivals,

if you want to know more, please send us an inquiry ASAP!

Hospital Containerized medical psa oxygen generator PSA oxigen plant Medical Oxygen Production Plant

Reviews

There are no reviews yet.