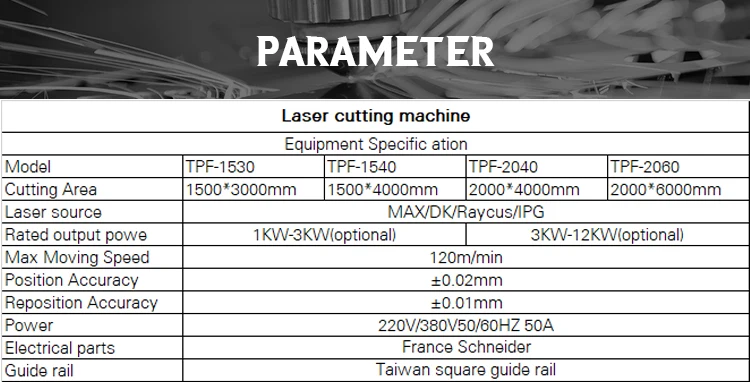

High Speed 1000W CNC Carbon Fiber Laser Cutting Machine with cost effective price

| The good machine body makes the equipment more stable in working, the light crossbeam makes it work faster; perfect industrial design is more in line with man-machine engineering; high quality electrical software control system gives equipment higher cutting precision. The machine owns more comfortable operation, more stable performance, more durable quality, higher cutting efficiency and wider application scope. |

|

Metal Laser Cutting Machine Features 1.It adopts advanced branded optical fiber laser core technology,good optical mode,stable performance. 2. The gantry flying light path design,light operation,saving about 40% electricity than competitors. 3. Achieve a perfect cutting effect by only blowing compressed air during processing,which can largely reduce costs of auxiliary gas such as Oxygen.Nitrogen about thousand dollars, 5. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine. 6.Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost. 7.Taiwan Hiwin 30mm square guide rails (high precision and less wear , with world famous taiwan hiwin self-lubricating sliding block) 8. Very low maintenance cost: no laser working gas; fiber transmission, no reflector; can save a lot of maintenance costs; |

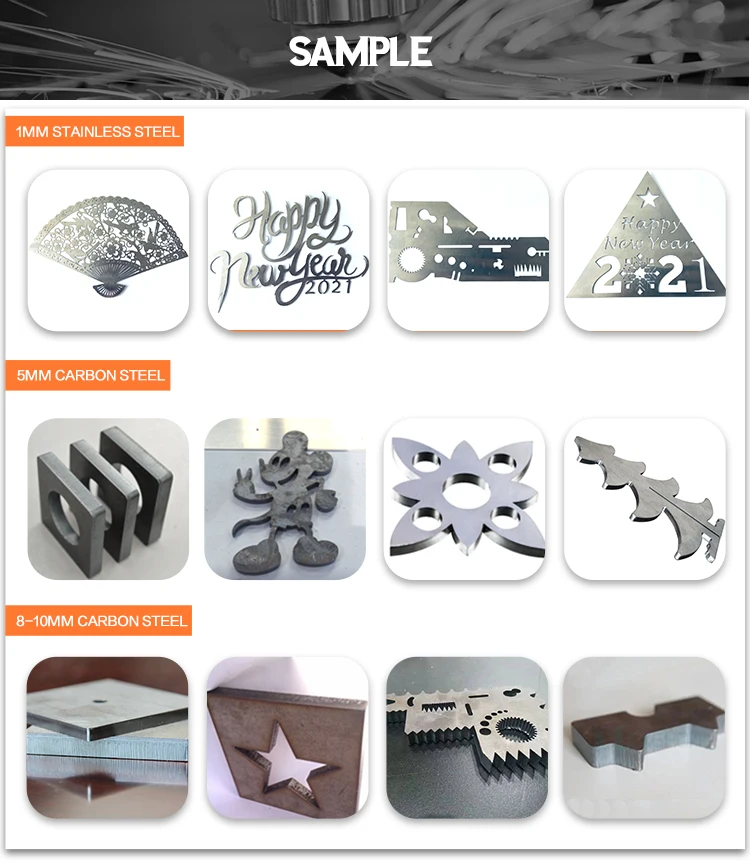

| Material :

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Industry : Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc. |

|

1.After Sales We provide 3 year’s guarantee and life-long maintenance for our products. Free repairing or replacement (except for wearing parts) is available for our products for their functional defects (except for artificial or force majeure factors) within warranty period. After warranty period, we only charge artifacts according to the actual situation.

2.Quality Control Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery.

3.OEM Service Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required.

4.Documents Support All Documents for clearance customs support : Contract ,Packing list,CommercialInvoice,Export declaration and so on. |

| Packaging detail:

1)Pack the machine with plastic sheet for clearing and damp proofing.

Shipping detail: |

|

Q: How can I choose the most suitable machine?

Q: What’s material can fiber laser cut?

Q: If we are interested in your machine, how to choose proper power?

Q:If some problems happen to this machine during warranty period, what should I do?

Q: How can I do if the machine goes wrong?

Q.If there is any technical help after we receive the machine? |

Reviews

There are no reviews yet.