be used for mining investigation, geological investigation, borehole for water well and observation well, borehole drilling for GSHP system and so on.

Features

1. All parts of the drilling rig are installed together on the turning platform with crawler chassis, it moves convenient and has good maneuverability.

2. Rig with power head has long feed stroke so that it can shorten the time of installing or unloading drill rods and improve the drilling efficiency.

3. Rig with full hydraulic transmission and control operates easily and flexibly. It can show smooth operation and reliable work.

4. Rig with dual -channel power head has strong torque as well as pulling force, it has strong ability to deal with accidents.

5. Machine installed a hydraulic clamping & breakout system in order to automatic wrench the drill pipe and tools, both assistant time and lobar intensity are reduced during the drill work.

6. Drill head with dual motor drive has a variable speed and wide speed range, it is suitable for the application of pneumatic DTH hammer drilling and alloy drilling.

|

Rig model

|

HF150RC

|

HF200RC

|

HF300RC

|

|

Borehole depth (m)

|

150

|

200

|

300

|

|

Borehole diameter (mm)

|

110-150

|

110-150

|

150-250

|

|

Drill head rotary speed (RPM)

|

21-158

|

43-150

|

48-190

|

|

Output torque of drive power head (NM)

|

7800

|

8000

|

8500

|

|

Drill head feeding stroke(mm)

|

3500

|

3800

|

3500

|

|

Drill head max lifting force (KN)

|

65

|

85

|

150

|

|

Drill head max feeding force (KN)

|

45

|

55

|

100

|

|

Hoist max lifting capacity (KN)

|

11

|

11

|

20

|

|

Engine power (KW)

|

Cummins 45+18.5

|

Cummins 45+22

|

Cummins 125

|

|

Drill machine Weight(Kg)

|

6800

|

8000

|

9800

|

|

Overall Dimension(L*W*H)(mm)

|

6500*2200*2400

|

6300*2000*2500

|

6800*2250*3100

|

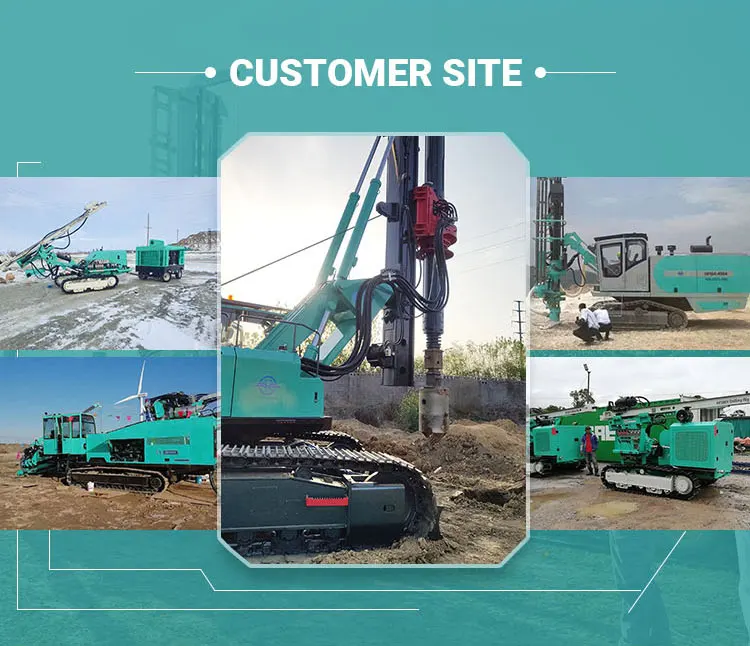

We are a professional manufacturer. Our factory mainly produces water well drilling rigs, core drilling rigs, down-the-hole drilling rigs, pile drivers, etc. The products have been exported to hundreds of countries around the world and enjoy a high reputation all over the world.

2. How is the quality of your machine?

Our products pass strict quality inspections before they leave the factory to ensure that they are qualified before they are shipped.

3. How to inspect the goods?

1) Support customers to come to the factory for on-site inspection.

2) Support customers to designate third-party companies to inspect goods.

3) Support video inspection.

4. Do you have after-sales service?

Yes, we have a dedicated service team that will provide you with professional technical guidance. If you need, we can send our engineers to your workplace and provide training for your employees.

5. How about quality assurance?

We provide a one-year quality guarantee for the main machine of the machine.

6. How long is your delivery cycle?

1) In the case of stock, we can deliver the machine within 7 days.

2) Under standard production, we can deliver the machine within 15-20 days.

3) In the case of customization, we can deliver the machine within 20-25 days.

Reviews

There are no reviews yet.