JBT102B is a portable edge banding machine using thermal-smelting glue. It uses PVC, ABS, melamine, wooden bands, which have been pre-cut into appropriated length, to band straight , curved and bevel edge. And it can be double-sided gluing and adjust the speed,user can operate freely.For small curved or straight board, the machines can be fixed on the console to execute edge banding operations easily. For large-area curved or straight board, user can hang the machine above the board to execute banding operations. This machine is compact, handy and flexible, easy to operate and provides perfect edge banding effect. It is an ideal choice for manufacturing and decoration work.

| Brand Name | Jackbond |

| Product name | JBT102B |

| Net Weight |

11 kg |

| Size |

380×300×310MM |

| Total power |

1000watt |

| Voltage | 220V/110V,50~60HZ |

| Edge thickness | 0.3-3MM |

| Edge width |

10-45MM |

| Processing rate | 0.5-5meter/min |

| Temperature |

120-180℃ |

| Forms of glue | double-siged glue |

| Gross Weight |

16kg |

| Package Volume |

37×35×42CM |

The portable edge banding machine can be placed on a small gantry for desktop wood edge sealing work. This operation is suitable for small wood edge sealing.

The following is the rendering of the edged wood board. The Jackbond edge banding machine is suitable for PVC edge banding, ABS edge banding, veneer edge banding, wood for NDF board, ecological board, particle board, wooden door, honeycomb board and other wooden boards.

The board can be fixed in place while the hand-held edge bander proceeds.It can also be used for small sized wooden boards while the machine is fixed onto a conveyor belt or table with stand. The process of edge banding is the same for normal sized loads.

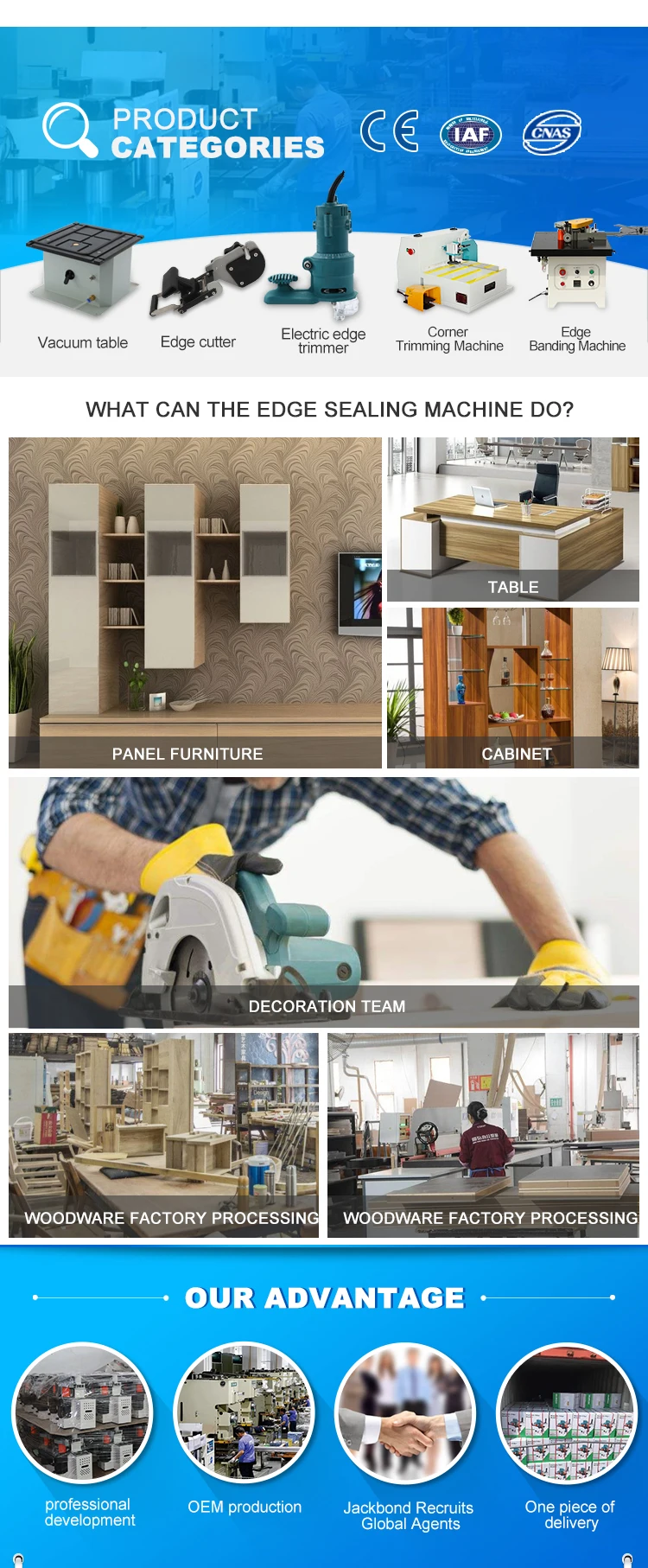

Our advantage:

1. We have a professional research & development team to improve our machines and create new machines according to customers request.

2. The electronic components are certified by the European Union, and about the core electrical components, we use Schneider ,all of which are high quality components.

3. Our products are self-developed and the core components are in stock, so we can guarantee delivery on time.

4. We have a professional pre-sales and after-sales service team to provide you with quality service.

5. We have 11 years of experience in manufacturing of woodworking machinery, and the quality of our products is more secure.

FAQ:

Q1: Are you the manufacturer factory or trading company?

A: We are the manufacturer with professional produce experience on woodworking machine morethan 11years. We own both of domestic and international sales department.

Q2: Where is your factory located? How can I visit there?

A: Our factory is located in Danzao Town,Naihai District,Fosahn City, Guangdong Province, China, You can take a plane to Guangzhou Baiyun International Airport. We will pick you up to airport!

Q3: How long is the delivery time? What’s your fast delivery time?

A: According to machine, it would be 10-15days after comfimation of payment,some machines are in stock. For non-standard machines and custom machines, depending on the customer’s specific requirements, it may take 15 to 30 days.

Q4: How to agent yours products?

A:You can purchase the samples for testing ,our products are certified by the European Union,and then you can contact the account manager to answer more detailed agency questions for you.Or contact us in any time,and welcome to our company! We display more new designs in our showroom to watch!!

Q5: How should I pay for my order ? what is the procession of this purchase ?

You can do 30% prepayment at first, then we will start to make production. when the machine is ready , we will take pictures to you, and then you can do the ballance. after we got your payment. We will send the machine to you.

Q6: How I can pay you?

A: We will write our account information in the contract, you only need to take the account number to bank payment.

Reviews

There are no reviews yet.