The whole set of equipment is compact, reasonable, make the waste full, complete and complete combustion, reduce fuel consumption,at the same time, the heat energy recovery efficiency is high, make the operation cost greatly reduced.

secondary spraying and activated carbon adsorption, to achieve the effect of harmless emissions.

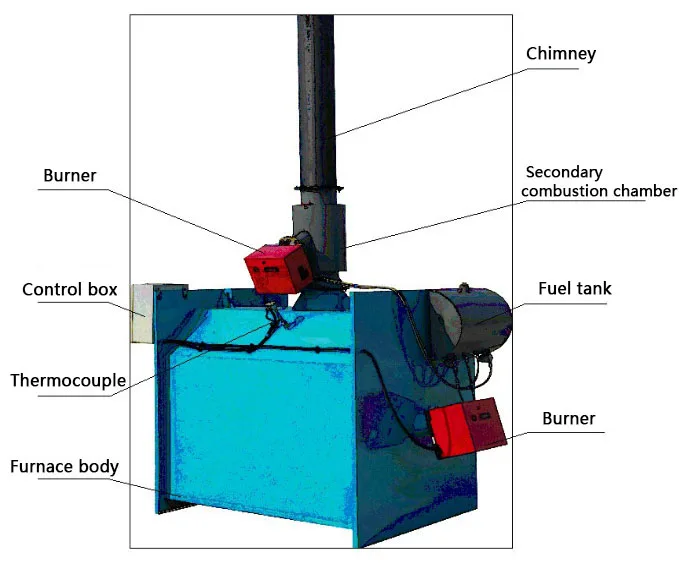

The incinerator installation includes:

Furnace body combustion chamber, secondary combustion chamber, primary burner, oil tank, secondary burner, electric control box, oil tank, chimney, spray tower, adsorption tower, induced draft fan.

|

Furnace type

|

Incineration capacity

|

Ignition mode

|

Fuel

|

Fuel consumption

|

|

horizontal furnace body combustion chamber

|

50Kg/h

|

automatic ignition

|

diesel

|

4-7kg/h

|

|

Feeding mode

|

Ash extraction

|

Design calorific value

|

Floor area

|

Heat burning rate of incineration residue

|

|

incineration furnace type

|

manual

|

200,000 CAL

|

HWL 1.7m×1.3m×1.8m

|

≥ 5%

|

|

Primary chamber incineration temperature

|

Secondary chamber incineration temperature

|

Incineration capacity reduction rate

|

Annual operation time

|

Total equipment area

|

|

≥850℃

|

≥1100℃

|

≥99.99%

|

≥2400 hours

|

10 square meters

|

3. Check all equipment lines to ensure normal power supply;

4. Ensure the water inflow is normal;

5. Put the crushed medical waste into the furnace, close the furnace door, and tighten the handwheel;

6. Startup process:

Step 1: Open the inlet valve and start the equipment after 3 minutes of normal water supply;

Step 2: Turn the draft fan knob to the open position;

Step 3: Turn the # 1 burner knob to the automatic position;

Step 4: Turn the # 2 burner knob to the open position, at which time the equipment enters normal operation.

7. Incinerate the garbage in the furnace and shut down the equipment after observing that there is no obvious fire or smoke

through the observation mouth;

8. Shutdown process:

Step 1: Turn the # 1 burner knob to the stop position;

Step 2: Turn the # 2 burner knob to the stop position;

Step 3: Turn the draft fan knob to the stop position;

Step 4: Cut off the main power supply of the equipment;

Step 5: Close the inlet valve.

9. After the ash is cooled, clean the ash out of the furnace

2. Check the furnace door seal after installation to ensure that it is tightly closed and there is no air leakage;

3. Pay attention to electricity safety;

4. The residual ash in the furnace shall be cleaned regularly, so as not to block the furnace and cause poor air circulationinside the furnace;

5. Spray tower is strictly prohibited to use for lack of water;

6. Operators should wear masks, gloves and other labor protection articles during operation;

7. When the equipment stops working, cut off the main power supply of the equipment and turn off the water and oil pipeline;

8. It is strictly prohibited to tear up the medical waste by hand or other equipment during the movement of the machine;

9. When the garbage in the incinerator is burning normally, it is strictly prohibited to shut down the induced draft fan, so as to avoid bad smoke and damage to the furnace and burner.

Henan Yuenai Trading Co., LTD. Is located in Anyang city, Henan Province, China.The company was founded in 2019 with a registered capital of 800,000 yuan.Henan Yuenai Trading Co., LTD. Is an industry and trade integration company, with a professional foreign trade sales team.In just one year time, I experienced hardships, still stick to the post, adhere to the principle of service first.I keep moving forward and growing.

Henan Yuenaitrade Co., Ltd. is the main medical products, the main products are: disposable ligator, disposable laparoscopic puncture, disposable wet heat exchange filter, disposable prepuce stapler, disposable negative pressure drainage bag, disposable medical bed sheet, medical incinerator, muscle vibration instrument and other products.Although it is only a year old, I have many foreign customers and keep good relations with them.Of course, we are also looking forward to working with you.

Q1: Are you trading company or manufacturer ?

Reviews

There are no reviews yet.