Products Description

|

Model

|

Full automatic sheath wire stripping and terminal crimping machine

|

|

Power supply

|

AC220V / 50 / 60Hz

|

|

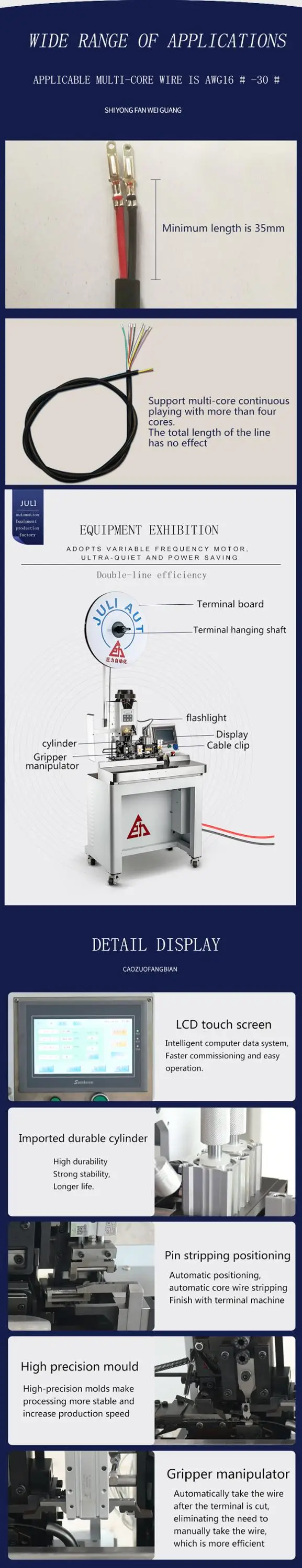

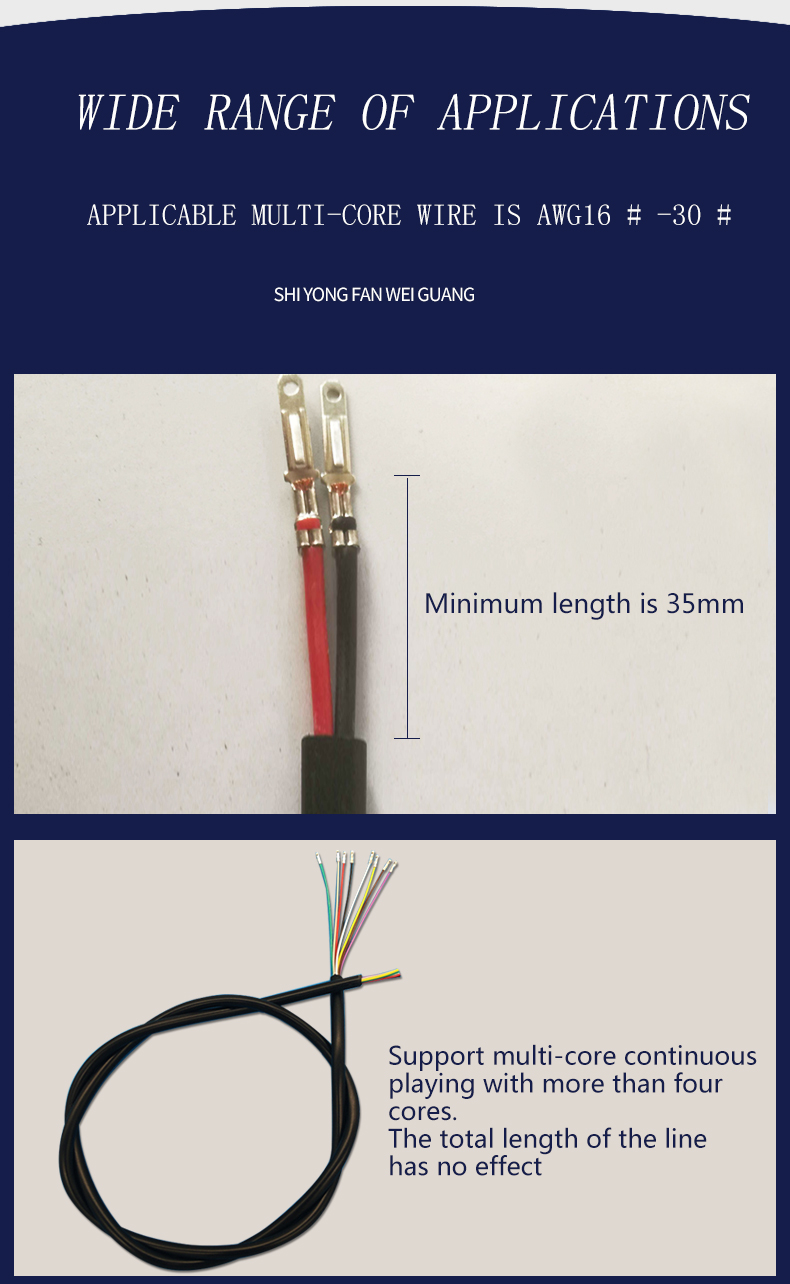

Machinable wire range

|

AWG16 # -30 #, 2-12P electronic wire terminal (depending on the wire)

|

|

Crimping capacity

|

1.5-2 tons

|

|

Applicable terminal

|

Various horizontal terminals

|

|

Sheath wire stripping length

|

4 core wire and above sheath minimum 35mm

|

|

Size

|

600MM * 800MM * 1350MM

|

|

Weight

|

90KG

|

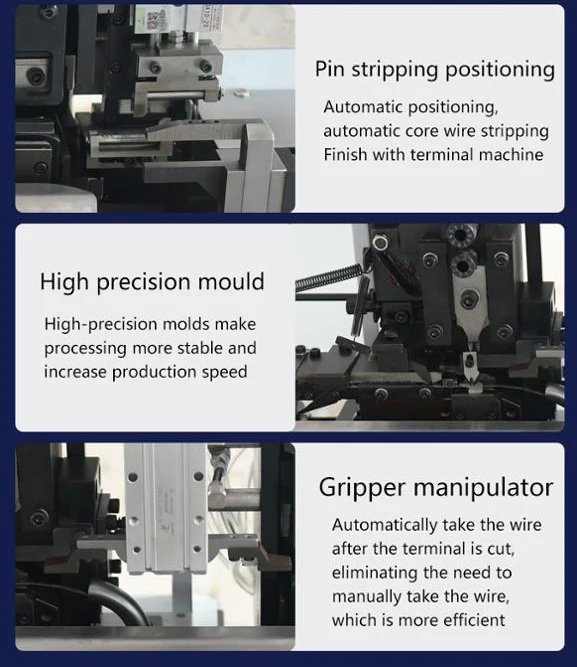

Features

1.This machine adopts advanced electronic control technology, and cooperates with closed-loop stepper motor plus high-precision control module and transmission mechanism, so that the stripping of the cable can be completed at one time. It has the characteristics of low noise, low power consumption and high efficiency. The improvement of the processing efficiency of the sheathed multi-core wire has obvious effects. Suitable for crimping of terminals between sheathed cores (16-28 wires).

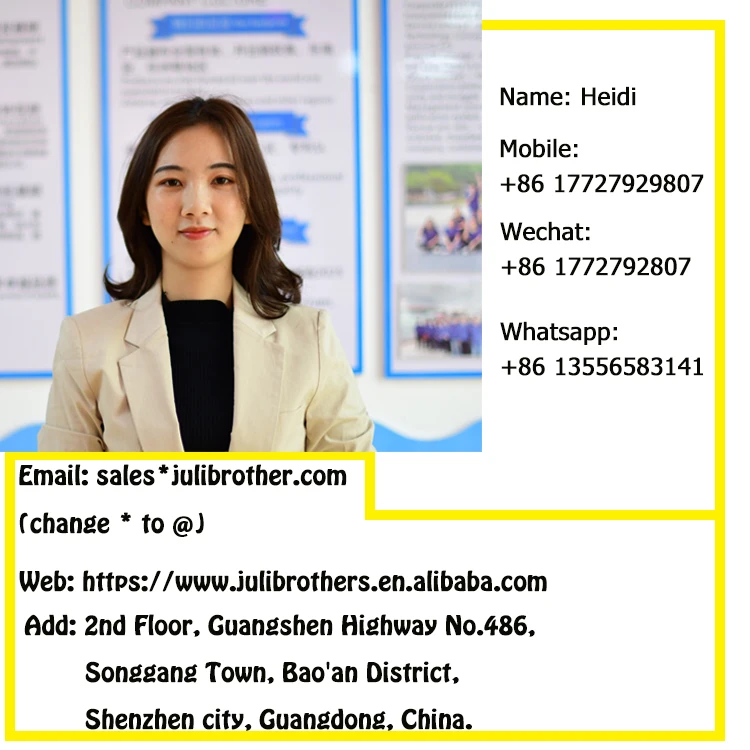

2. The wire stripping motor of this machine is translated, the movement speed is fast, and the positioning is accurate. The

stripping skin is easy to recycle, and the machine is clean, tidy and highly accurate. Single and continuous 1-12P cores can be set. For raw and experienced operations, the machine can adjust the machine’s working speed through a touch screen to adapt to the operator’s proficiency.

3.The machine adopts screen adjustment, which is fully automatic and intelligent.

4. The terminal machine adopts ultra-quiet environmental protection and energy saving, low loss, suitable for the end processing of various types of wires.

5. Adopting automatic thread positioning and wire feeding and cable management device, the machine will automatically straighten and straighten the wire, overcoming the problem that the previous pay-off position is inaccurate and the defective product is too high. With automatic take-up function.The child automatically puts out the line.

It overcomes the problems of multi-core wires, hard-to-handle terminals and excessive defective products, which greatly improves production efficiency and profits.

2. The wire stripping motor of this machine is translated, the movement speed is fast, and the positioning is accurate. The

stripping skin is easy to recycle, and the machine is clean, tidy and highly accurate. Single and continuous 1-12P cores can be set. For raw and experienced operations, the machine can adjust the machine’s working speed through a touch screen to adapt to the operator’s proficiency.

3.The machine adopts screen adjustment, which is fully automatic and intelligent.

4. The terminal machine adopts ultra-quiet environmental protection and energy saving, low loss, suitable for the end processing of various types of wires.

5. Adopting automatic thread positioning and wire feeding and cable management device, the machine will automatically straighten and straighten the wire, overcoming the problem that the previous pay-off position is inaccurate and the defective product is too high. With automatic take-up function.The child automatically puts out the line.

It overcomes the problems of multi-core wires, hard-to-handle terminals and excessive defective products, which greatly improves production efficiency and profits.

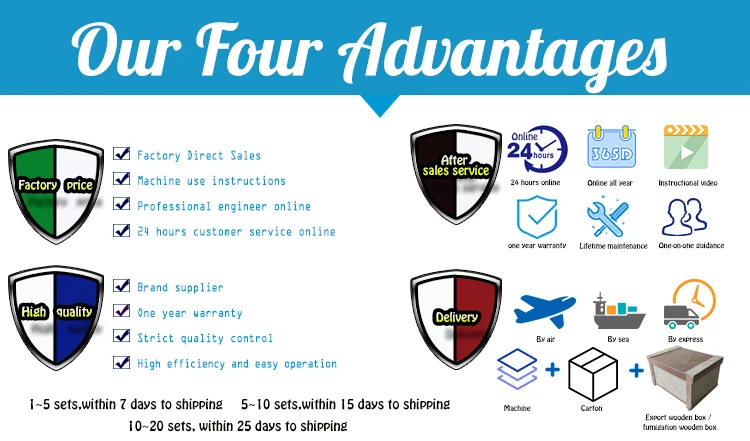

Contact us

Company Information

Certifications

Packaging & Shipping

FAQ

Reviews

There are no reviews yet.