Fiber laser cleaning machine laser rust removal laser cleaner customization

Integrated mobile system: built-in water cooling, control system, laser head and necessary accessories

Ultra-light dual-purpose one-dimensional laser head: 1D one-dimensional laser head <3KG

One machine has two functions: handheld and automatic laser head switching time <3 seconds

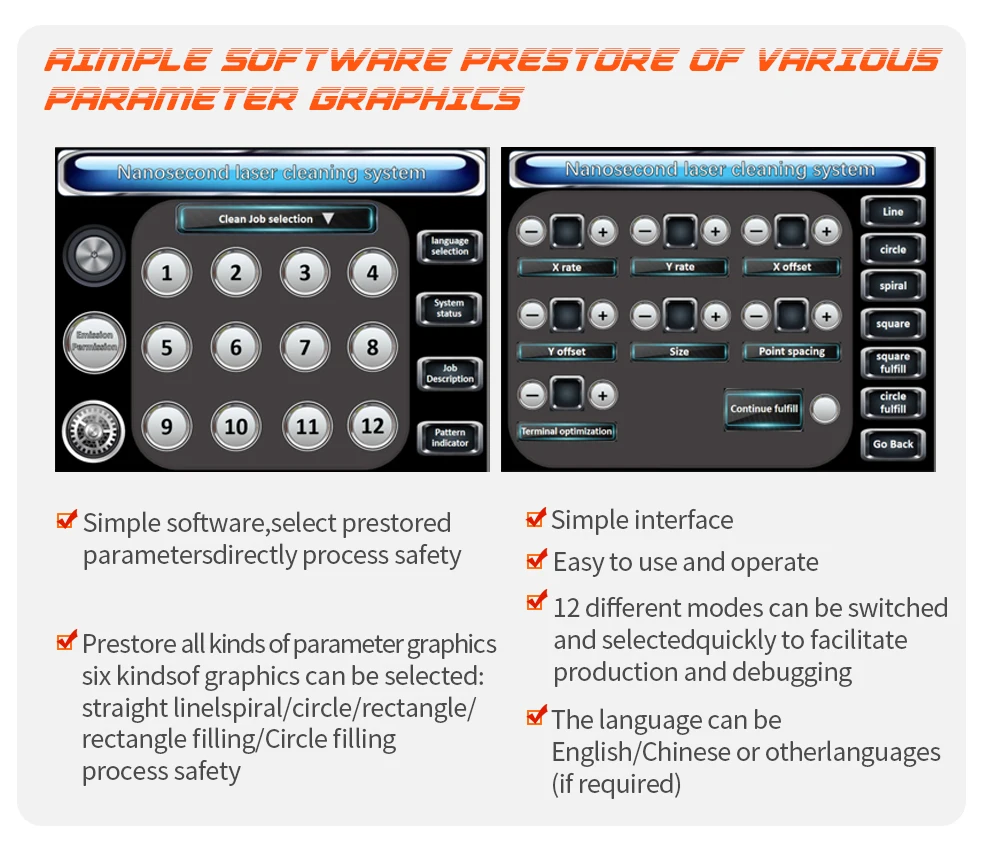

One-key operation: dual operation interface for advanced users and ordinary users

High-quality parts and accessories: All parts are made by internationally renowned brands to ensure quality

Preset various parameter graphics: multiple graphics are built in the system and directly call processing parameters

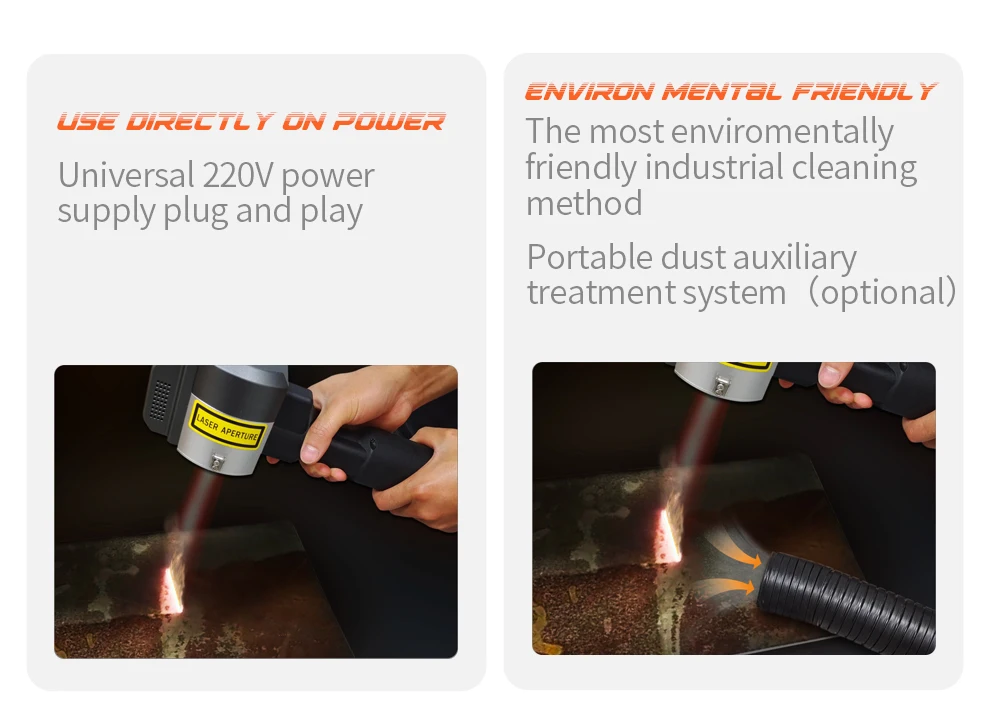

Convenient power requirements: universal 220V power supply, plug and play

Green and pollution-free: recognized as the most environmentally friendly industrial cleaning method

World-class process support: Returned doctors and master teams provide comprehensive process and technical support

|

Low and medium power nanosecond pulse series (200W air-cooled)

|

||

|

Max average power(W)

|

200

|

300

|

|

Power range(%)

|

10 – 100

|

|

|

Max peak power(KW)

|

8–10

|

|

|

Output central wavelength(nm)

|

1064

|

|

|

Bandwidth(nm)

|

≤ 10

|

|

|

Max pulse energy(mJ)

|

10

|

12.5

|

|

Pulse repetition rate(kHz)

|

20-50

|

|

|

Pulse width(ns)

|

90-150

|

130-140

|

|

Power stabiliti(%rms)

|

<5

|

|

|

Beam quality(M2)

|

5

|

|

|

Fibre length(m)

|

75

|

|

|

Min bending radius (mm)

|

220

|

|

|

Power Consumption(W)

|

<2300

|

<3500

|

|

Operating temperature(℃)

|

10 – +40

|

|

|

Storage temperature(℃)

|

-20- +60

|

|

|

Relative humidity(%)

|

≤ 80

|

≤ 70

|

|

System dimensions(L × W × H, mm)

|

980 × 613× 1096

|

|

|

Total weight(Kg)

|

169

|

|

|

Laser head weight(Kg)

|

≤3

|

|

|

Laser head type

|

1D/2D scanning

|

|

|

Laser head scanning range(mm x mm)

|

100 × 100

|

|

|

Laser head focus length(mm)

|

160,254,330

|

|

|

Laser head operating mode

|

Manual/Auto

|

|

|

Laser safety classification

|

Class 4

|

|

Small area or local cleaning applications, paint removal, red rust removal, black rust removal, oil removal; stainless steel and aluminum alloy and other alloys before and after welding; removal of copper oxide, zirconia, etc., metal surface wool and surface wiredrawing.

As per your actual address, we can effect shipment by sea, by air, by truck or railway. Also we can send the machine to your worksite as per your requirement . Nude Packing for big parts after plastic film covering. The small parts packed into wooden cases which is suitable for seaworthy transportation.

Pre-services

2. Sample testing support.

3. View our Factory.

4. Strict quality inspection before leaving the factory

2. Customers may come to our factory directly for learning and training. We offer the training, including machine installation,

drawing operations , operation, machine trouble shooting, and maintenance.

3. Our company provide life long technical service for our machines.

4. Regular visits or telephone interviews to acknowledge the equipment usage.

Reviews

There are no reviews yet.