Factory supply woodworking machine Wood/pipe furniture industrial cnc carving equipment

|

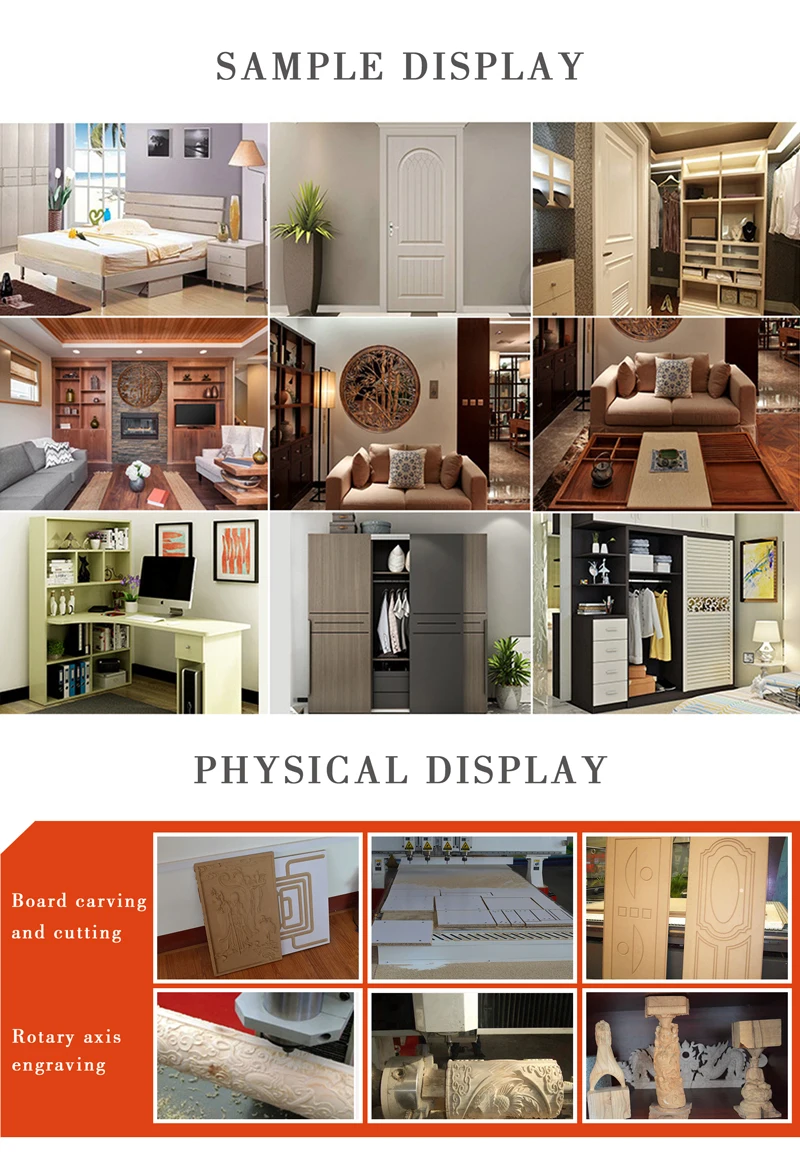

Woodworking industry: furniture decoration, musical instrument manufacturing, plane carving of wooden crafts, solid wood furniture, MDF paint-free doors, composite doors, cabinets, wardrobes, windows and doors, bedside cabinets, etc.

Decoration industry: art models, art murals, screen relief carving and cutting, decoration processing, gift packaging, wave boards, electrical countertops, sporting goods and other wooden industrial products.

Advertising industry: Acrylic, two-color board, PVC, ABS board, aluminum board, aluminum-plastic board engraving V-shaped slot cutting, two-color portrait, three-dimensional billboard, various signs, badges, coordinate plates, copper, fonts, fonts, various Class signs, trademarks, etc. Engraving and cutting of various sheets. |

Main details

Main parameters

Main features

|

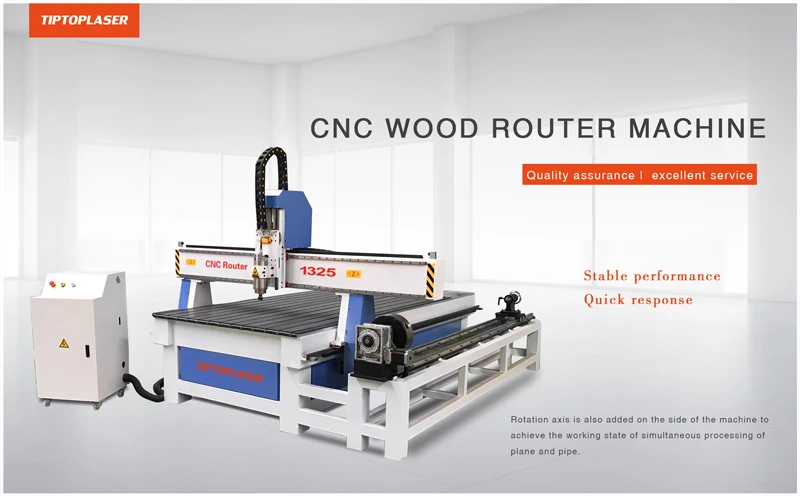

1.It adopts high-precision linear square guide rail, double-row four-row ball slider, large bearing capacity, stable operation, high precision and long life.

2.Using high-speed drive stepping motor and driver, with the brand air-cooled constant power engraving and milling spindle, so that the engraving speed is increased.

3.The all-steel structure adopts the table top of the heavy-duty machine tool and the gantry beam structure, and the structure is stable.

4.Intelligent processing cross-border protection to prevent mechanical collision caused by design layout exceeding the processing width.

5.Multiple software compatibility. Advanced professional control system, compatible with multiple software Type3/Artcam/Castmate/Pro-e/Ug/Cad/Illustrator, etc.

6.High-speed processing. High kinetic energy, Y-axis dual-motor drive, consistent curve and linear speed.

|

| The design and layout are carried out through the special engraving software configured in the computer, and the information of the design and layout is automatically transmitted to the engraving machine controller by the computer, and the controller converts the information into a belt that can drive a stepper motor or a servo motor. Powerful signal (pulse train) controls the host of the engraving machine to generate X, Y, Z three-axis engraving tool path base path. At the same time, the high-speed rotating engraving head on the engraving machine cuts the processing data fixed on the worktable of the host machine through the tools configured according to the processing material, and can engrave various flat or three-dimensional relief graphics and characters designed in the computer , Realize the automation of carving. |

| 1. We will purchase transportation insurance for the machine. If the machine is damaged after receipt, please contact us in time. 2. We use strong fumigated wooden boxes to pack and transport the goods. There will be soft materials on the surface of the machine to prevent the machine from colliding during transportation. 3. We have three modes of transportation, sea, land, and air. Please tell us the city closest to you and we will calculate the most favorable transportation method for you. |

|

Pre-sale service: After-sale service: |

|

1. If I don’t know anything about the machine, how can I choose the one that suits me?

2. How to ensure the quality of the machine?

3. When I bought this machine, I didn’t know how to use it. what should I do?

4. What should I do if there is a problem with this machine?

5. What is the minimum order quantity? |

| Shenzhen Tip-Top International Trade Co. , Ltd is a branch company with engineers and research and development for 16 years. It mainly sells optical fiber marking machines, optical fiber cutting machines, woodworking CNC engraving machines, laser engraving machines, laser welding machines and plasma machines.We are a professional manufacturer engaged in research, development, production and sales, we have our own factory. Our products are mainly sold to Europe, America, North Africa, Australia and many other countries, and received good reviews from customers. We are pursuing long-term cooperative development, not one-off sales. We strictly control the quality and use high-precision accessories to reduce errors. Welcome to visit our factory. |

Contact us

Reviews

There are no reviews yet.