wooden broom handel machine diamond saw blade sharpen cnc lathe

1 machine =24 workers

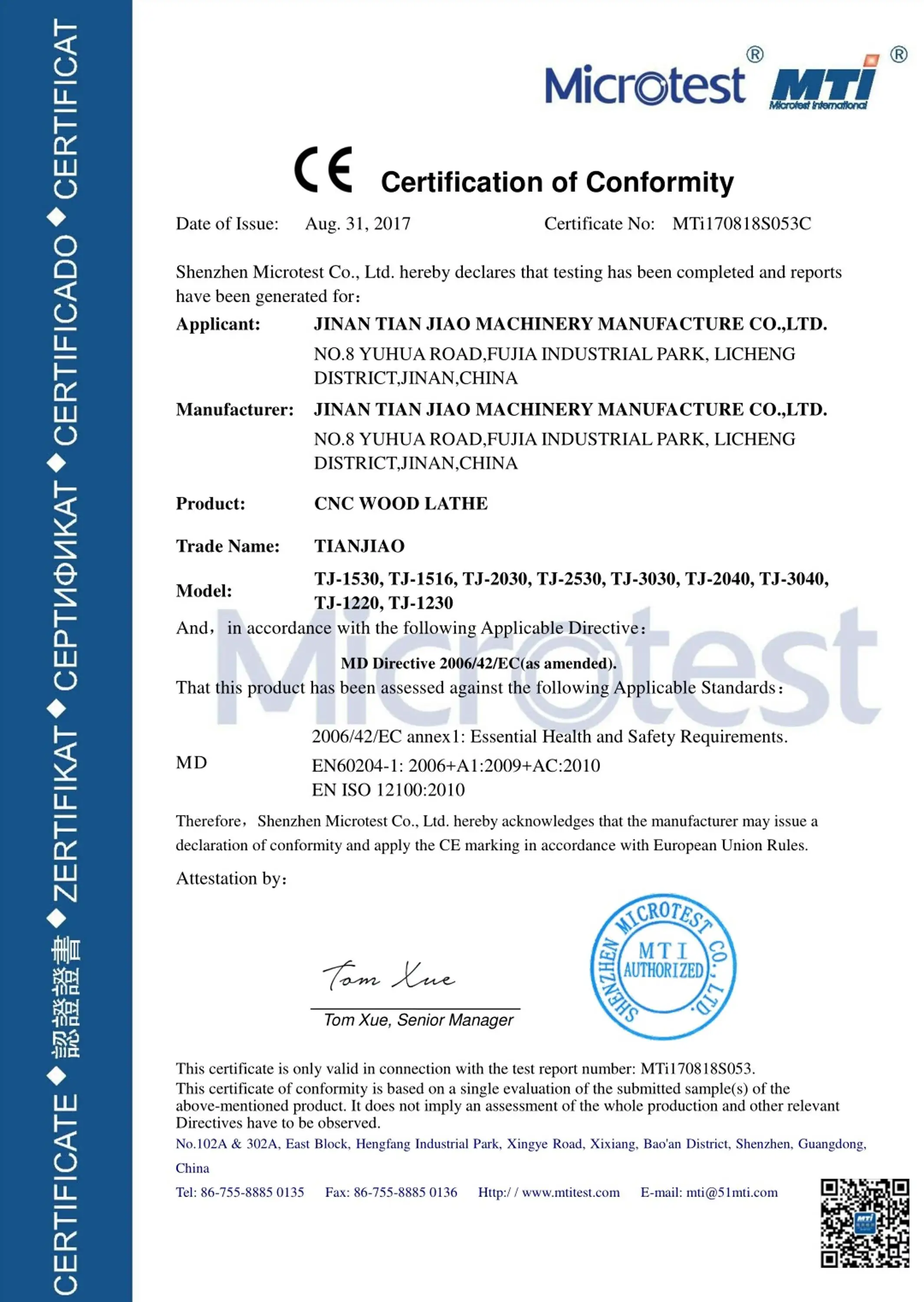

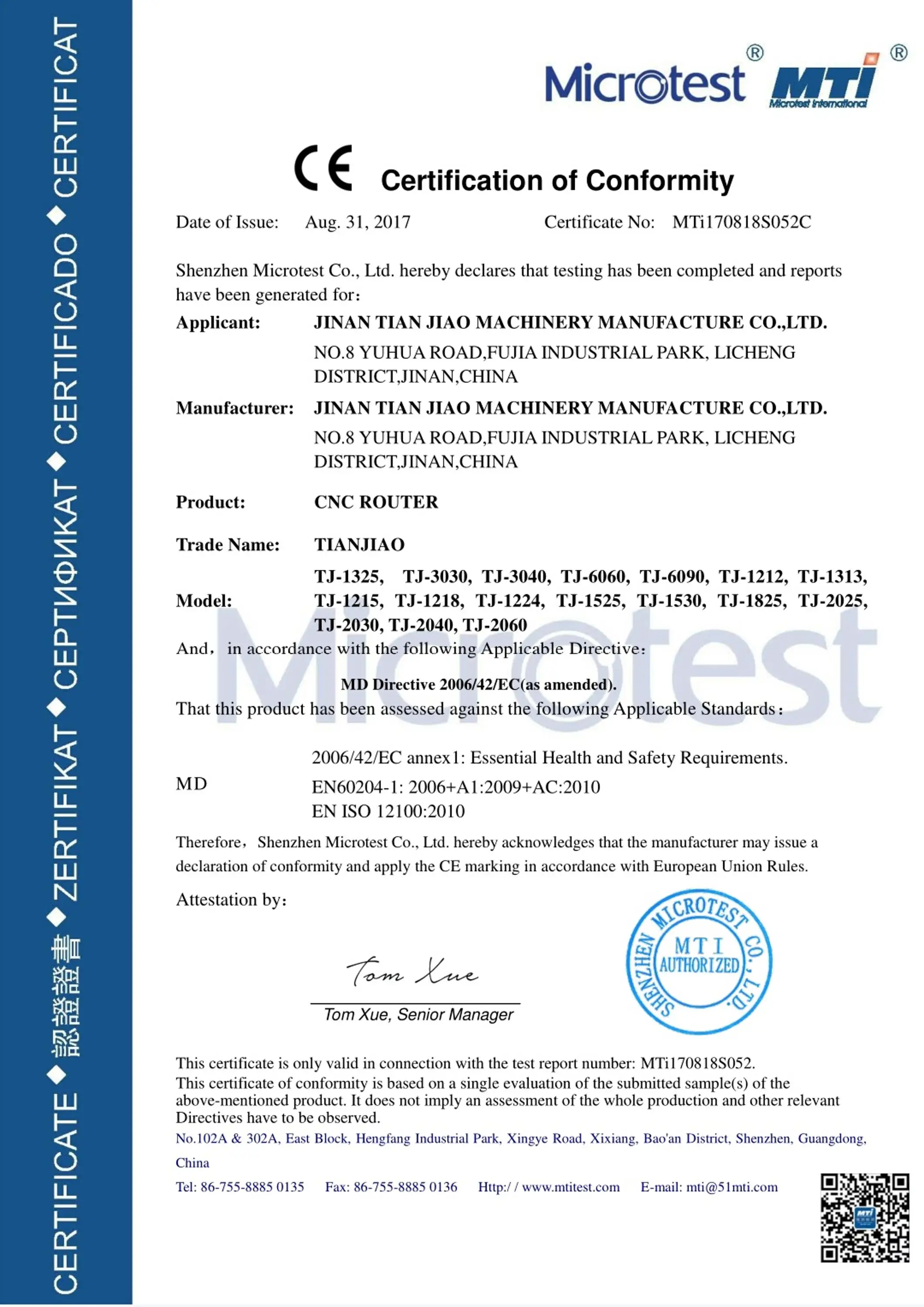

1.Detailed Features:

1. Whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, so the lathe body is stabilized and will not be deformed forever.

2. Professional used for wood turning and wooden cylinder engraving, for table legs, stair railing (banisters), etc. wood cnc turning lathe

3.Adopting advanced DSP system with USB connection, operated with the handle, convenient operation. Our engraver can completely work off-line and do not take any computer resources.

4. Adopt Germany ball screw and taiwan PMI helical square rail with high transmitting precision and longevity. Bid module helical/diagonal rack.

5.Compatible with several CAD/CAM design software, e.g. type3, artcam, etc.

6.Rotating speed is adjusted by inverter, and the speed data is shown on controlling cabinet panel

7. One time tool setting to finish the whole work piece.

2.Technical Parameters:

|

Model |

TJ1530/TJ2030/TJ2530 |

|

Max turning length |

100-300mm or option |

|

Max turning diameter |

300mm/300mm/160mm |

|

Number of axis |

2 axises 1 blade/1 axis 1 blade/1 axis 2 blade or option |

|

Maximum feed rate |

200cm/min |

|

Minimum setting unit |

0.01cm |

|

Spindle motor power |

4kw |

|

Air pressure |

0.6-0.8Mpa |

|

Power supply |

AC380v/50hZ or 220v/50hz or option |

|

Overall dimensions |

300*110*170cm |

|

Weight |

1600kgs |

|

Control |

DSP |

|

Driver |

Stepper motor |

3.Suitable Materials and Industrial Applications

>>Applicable Material:

Various wood materials can be processed, such as beech, oak, pile of wood, birch, teak, Sapele, ashtree, merbau, sandalwood, rosewood and other wood material.

>>Applicable Industry:

For the production of solid wood furniture, solid wood staircase, wood columns, solid wood floor racks, wood decorative, wood crafts, such as rotating working pieces machining. Applies to furniture, staircases, decorative, wooden crafts manufacturing factory, etc.

The final products include various cylindrical working pieces, bowl shape, tubular shape and vehicle wood crafts, such as various staircase column, Roman column, general column, tables or chairs legs, washstand, wooden vase, wooden table, baseball bat, car wooden furniture, children’ s bed column, etc.

4.Main Parts

Optional parts:

1. More rotary axis

2. Spindle

3. Different power requirement

4. Upgrade controller

5. Servo motor

6. Bigger working diameter and length, etc.

5.Sample Processing Show

6.Packing Show:

Whole machine will be totally wrapped with cling plastic to avoid rusting during shipping,then fastened on the stronger iron steel tube pallet with wooden box for sea shipment.

Inside Packing

· Use professional Stretch Film to cover the whole lathe.

· Stretch film package with foam protection in each corner.

Outside Packing

· Sandard export wooden cases and pylwood cases.

· Save space as much as possible for container loading.

Transport

· We support shipping, air, land and express.

Packaging details

outside package : standard marine export plywood caseInner package: stretch film and plastic film for humidity

PS: We can also make package according to your requests.

7.Fair and Customers

8. After sale service

Guarantee:

12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong

with the machine, you will get spare part for free. Out of 12 months, you willget spare parts at cost price.

You will also get technical support and service all the lifetime.

Technical support:

1. Technical support by phone, email or Skype around the clock.

2. Friendly English version manual and operation video CD disk.

3. Engineer available to service machinery overseas.

After sales services:

Normal machine is properly adjusted before dispatch. You will be able to use the machineimmediately after received machine.

Besides, you will be able to get free training advice towards our machine in our factory. You willalso get free suggestion and consultation, technical support and service by email/fax/tel etc

9. Other Products

You can tell us the working piece material, size, and the request of machine function. We can

recommend the most suitable machine according to our experience.

Q2: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can

also help you by “Team viewer”online, with telephone or Skype explain.

Q3: Can you customize the machine for me?

Yes, we provide customized solution, but considering the cost, we will recommend the

standard configuration to you first.

Q4: What is the guarantee? In case the machine break down?

The machine has 1 year guarantee, fail parts will be replaced for free if the machine under

“ normal operation”.

Q5: How about the documents after shipment?

We will send all the documents by air after shipment. Including packing list, commercial

invoice, B/L, and other certificates required by clients.

Q6: Delivery time?

For standard machine, it would be 7-10 working days; for non-standard machine, it would be

20 – 30 working days.

Q7: How is the payment?

Normally we accept T/T or L/C, if you like other terms, tell us in advance.

Q8: Do you arrange the shipment for me?

For FOB or CIF price, we will arrange shipment for you, for EXW price, you should arrange

the shipment by yourself.

Q9: How is the packing?

Step1: water proof wrapping film with foam protection in each corner.

Step2: Solid seaworthy wood box package with steel belt.

Step3: Save space as much as possible for container loading.

Reviews

There are no reviews yet.