Product Description

Features

▷Back-seal packaging, valve plug pump filling and metering

▷Film sterilization, liquid material sterilization

▷Back-seal packaging, valve plug pump filling and metering

▷Film sterilization, liquid material sterilization

▷The finished product bag is exquisite and reliable, hygienic and safe

▷Assemble the photoelectric control device to ensure the integrity of the packaging bag pattern

▷Automatically complete bag making, measuring, filling, sealing, cutting, counting,printing batch number

▷The shell and material contact parts are made of stainless steel

▷Assemble the photoelectric control device to ensure the integrity of the packaging bag pattern

▷Automatically complete bag making, measuring, filling, sealing, cutting, counting,printing batch number

▷The shell and material contact parts are made of stainless steel

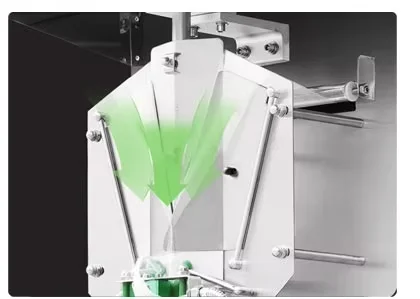

Forming device

Easy Changing by Film width,

Film Fast once forming.

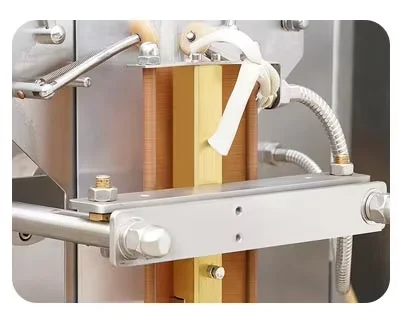

Vertical sealing

Pure copper heats up quickly.

Good thermal conductivity, zero

deform.

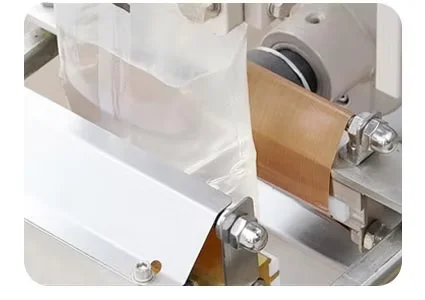

Coding part

Ribbon and steel stamp are available.

Can be equipped with a ribbon.

Sealing and Cutting

Pure copper heats up quickly, the

seal is beautiful and firm.

One-way valve

Fast suction, with a check valve device, no material will be stopped when the machine stops.

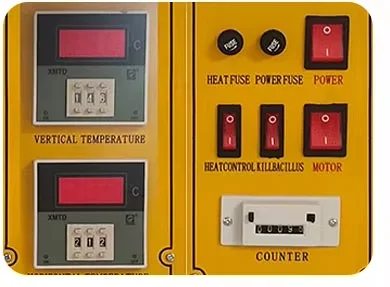

Control Panel

Humanized design control panel, easy to operate Adjust temperature,

automatic counting, germicidal

lamp, etc.

Temperature control

The quality is more stable than ordinary temperature controllers, and can be set with small deviations.

Material

The parts contacting the bag are made of stainless steel 304,It is corrosion resistant.

High temperature resistance,

And it has a long service life.

Specification

|

Model

|

TC-1000

|

TC-2000

|

|

Film Developed Width (mm)

|

240/320mm

|

380/460 mm

|

|

Packing speed(bags/hour)

|

1500-2000 Bags/H

|

1000-1500 Bags/H

|

|

Power(KW)

|

1.6kw

|

2.5kw

|

|

Overall Dimension(mm)

|

880*760*1950mm

|

1050*850*2050mm

|

|

Weight(KG)

|

350kg

|

400kg

|

Reviews

There are no reviews yet.