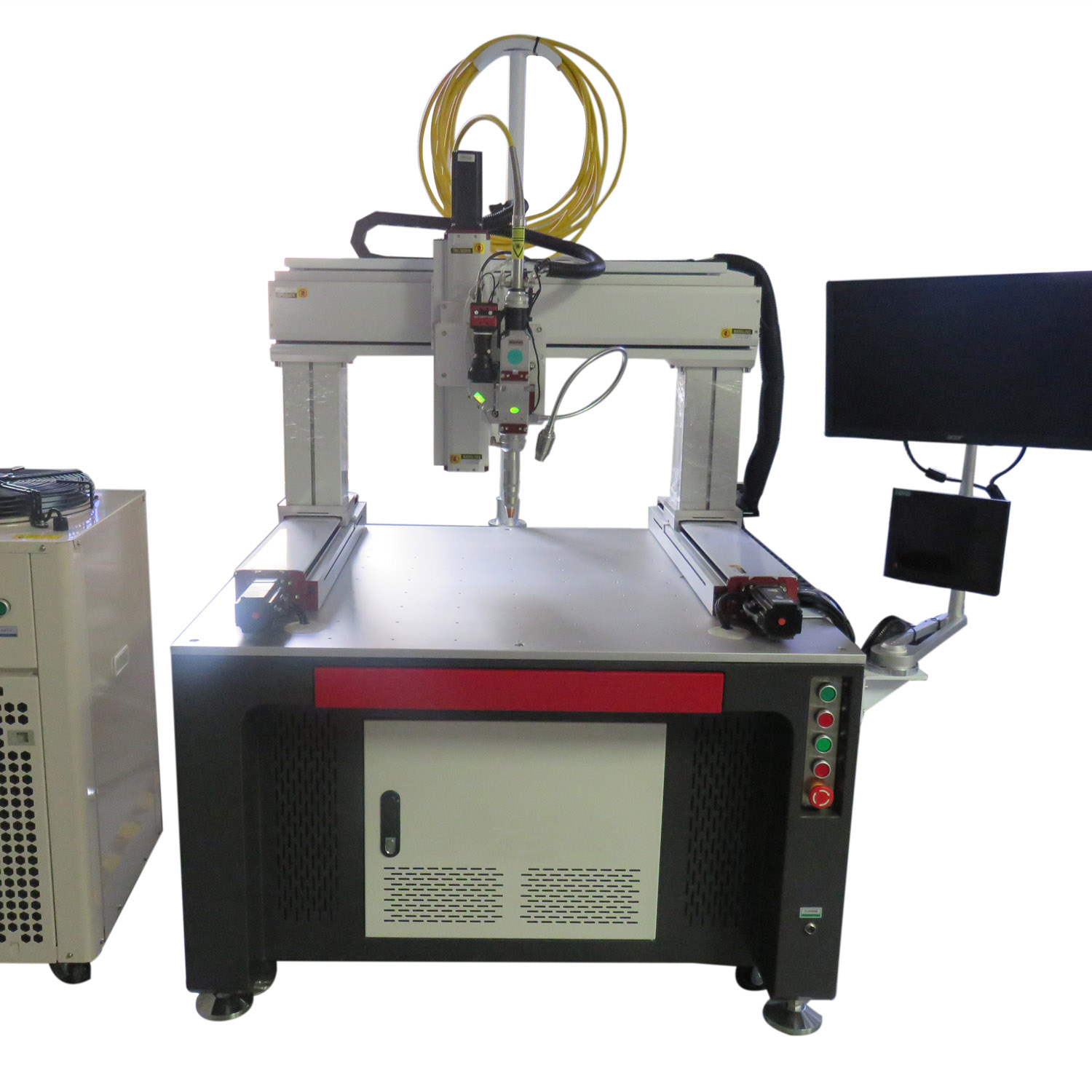

| Easy to operate 4 axis 1000W raycus fiber laser welding robot |

|

Jinan hanteng laser technology CO. |

|

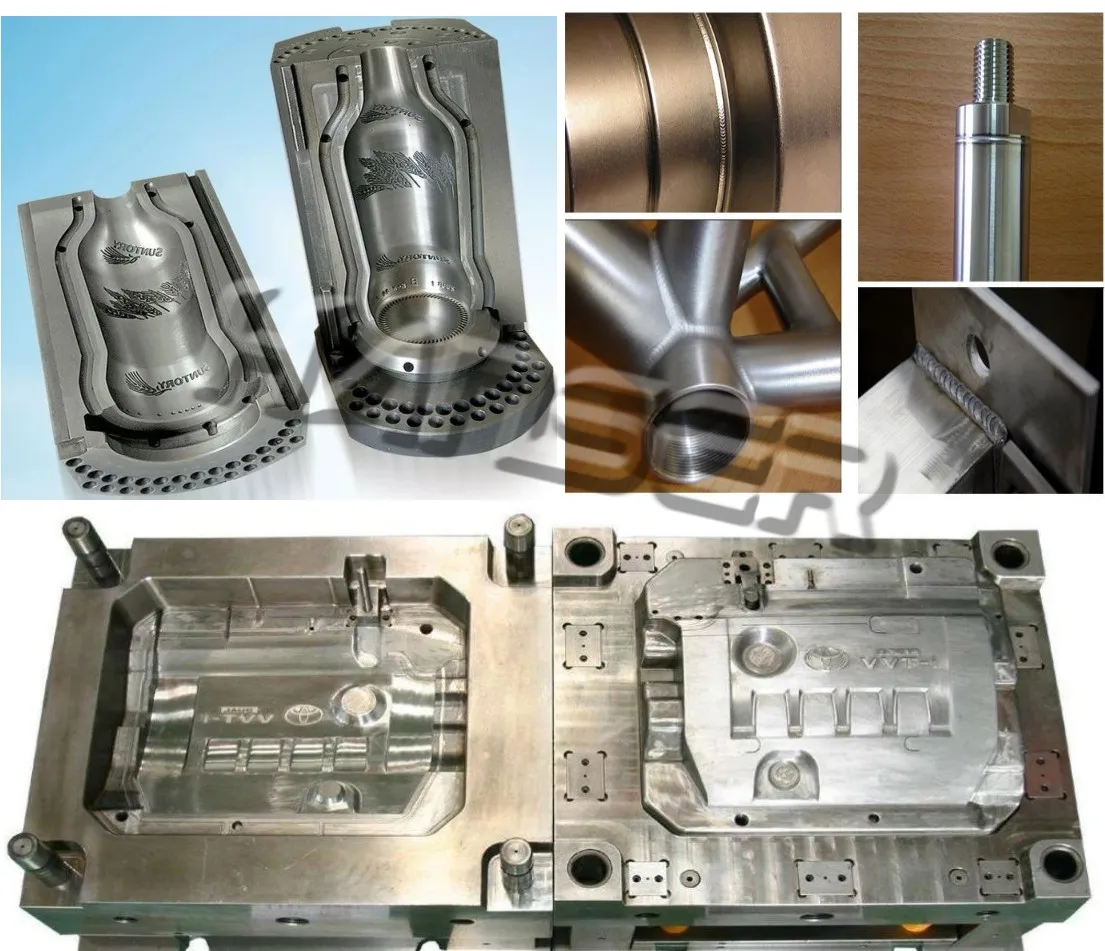

Four-axis CNC automatic welding machine

1)the main structure The main machine of the CNC automatic welding machine includes X, Y, Z axis linear motion and R axis rotary motion to realize the linear or curved motion of the welding space and the welding angle adjustment of the welding torch to the workpiece, thereby completing the welding of various special-shaped welds. The X, Y, and Z axis motion systems are driven by AC servo motors, driven by ball screws and guided by guide rails to achieve precise control of walking. It can manually adjust and control the welding angle adjustment requirements of the welding gun and the workpiece, and cooperate with the X, Y, and Z axes to achieve the completion of the welding process. |

![qq20200106165918[1].jpg](http://sc01.alicdn.com/kf/Hc60679c91ac04fb591739d972944c116c/233042446/Hc60679c91ac04fb591739d972944c116c.jpg)

|

Features:

1.The X, Y, Z, and D axes of the workpiece to be welded are step-driven to meet the needs of large strokes 2.High production efficiency, fast welding speed and automatic batch production 3.Can weld any point, straight line, circle, elliptical machine square and other arbitrary trajectories 4.With auto focus and rotation functions, it can weld products of any shape in 3D space |

|

|

| The OSPRI LW410 welding head has a body size of 55 × 55 and a weight of only 2.8KG, which makes it suitable for robots and robots. Drawer-type lens installation facilitates the installation and replacement of various specifications of collimating lenses and focusing lenses, and the entire system is integrated by waterway. LW410 is equipped with CCD and display module, and can be equipped with vision software for welding. The external red light alignment module can quickly and accurately find the original laser focus position. Horizontal anti-splash air curtain device can effectively reduce the damage to the protective glasses caused by spatters during welding |

![_20191106112253[1].jpg](http://sc02.alicdn.com/kf/Haf720885bf484e7a8fdb620dc9f6e7a0Q/233042446/Haf720885bf484e7a8fdb620dc9f6e7a0Q.jpg) |

|

Product advantages:

1. The ceramic cavity imported from the United Kingdom is used for high photoelectric conversion efficiency. 2. CCD image monitoring ensures the stability of welding quality. 3.Specialized automatic tooling fixtures can be customized to achieve mass production of products 4. The laser power density is large. After the workpiece absorbs the laser, the temperature rapidly rises and melts or vaporizes, even if the melting point is high, the hardness and brittle material are high. Materials (such as ceramics, diamonds, etc.) can also be processed by laser; 5. The laser head is not in contact with the workpiece, and there is no problem of wear of processing tools; 6. The workpiece is not stressed and is not easy to be polluted; 7. It can process the moving workpiece or the material sealed in the glass shell; 8. The divergence angle of the laser beam can be less than 1 milli-arc, the spot diameter can be as small as micrometers, and the action time can be as short as nanoseconds and picoseconds. Rate laser’s continuous output power can reach kW to ten On the order of kilowatts, the laser is suitable for both precision microfabrication and large material processing; 9.The laser beam is easy to control, and it is easy to combine with precision machinery, precision measurement technology and electronic computer to realize high automation of processing. And achieve high processing accuracy; 10. Robots can be used for laser processing in harsh environments or places that are difficult for others to access. |

|

|

|

Jinan Hanteng Laser Technology Co., LTD. is a laser automation equipment manufacturer integrating R&D, design and production. Products include laser marking machines, laser welding machines, laser engraving machines, laser cutting machines and other non-standard automation equipment. Han Teng laser are striving for excellence in product quality.pay attention the the details from the accessories to the whole machine. “Result-oriented, we are born for quality” is the corporate philosophy of HanTeng Laser. “Excellent quality, reliable price” is Han Teng business purpose of laser. Faced with fierce competition in the market, Han Teng Laser understands that responsibility and hard work are the foundation of our business success. "The road is long and its repairs are far-reaching." We are striving to continuously explore the development of the laser industry and dedication to create more high-quality products for the community. |

|

|

|

|

|

|

Q: How to operate the machine? is training necessary? A: The machine is mainly controlled by software. Before shipment, we will make a simple operation manual with pictures and provide user manual of software. Generally speaking, an operator, who is not familiar with fiber laser printing machine before can still operate it very well. According to customers’ requests, we can send our technician to customer’ plant for machine training or customers can come to our plant for machine training if needed.

A: We provide three years machine warranty. During the two-year warranty, in case machine exists problem, we will provide parts required with free of charge by express. But as for the parts damaged by artificially, it does not fall within our warranty list. After the warranty, we still provide lifetime service.Thanks.

Q: How to choose a suitable machine?

Q: What’s consumables of laser marking machine?

Q:This is the first time I use this kind of machine, is it easy operate?

Q: What’s consumables of laser marking machine? A: It does not have consumable. It’s very economical and cost effective.Thanks. |

Reviews

There are no reviews yet.