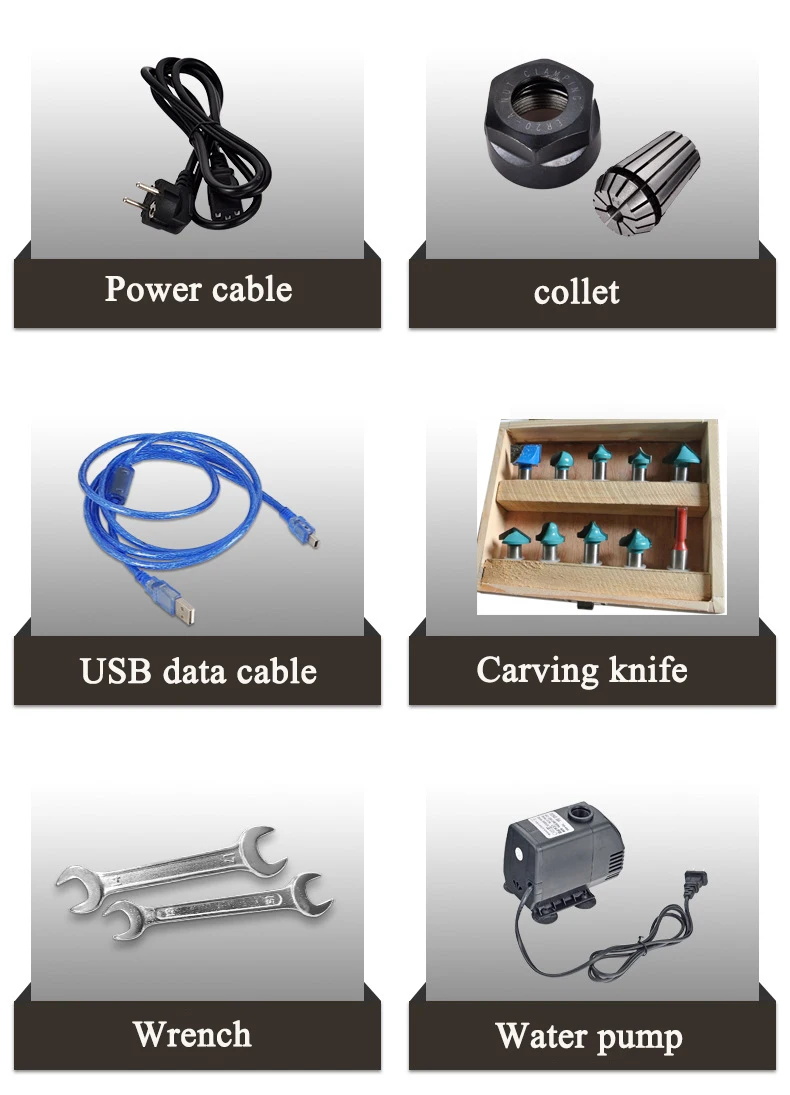

Discount price wood router Wooden door engraving machine / CNC router wood furniture making/wood carving equipment 1325

| Advantages |

|

1: Adopting the thicker and bigger welded steel tube frame, it is suitable for engraving hardwoods.

2: Manufactured with powerful water cooling spindle, it is the perfect choice for carving.

3: Equipped with the imported components, which greatly guarantee the long service life of the machine.

4: High-strength body design and Y-axis dual-motor drive, the design is more reasonable, the processing speed is fast, the maintenance is simple, and the fault is low.

5: Advanced CNC machining system, powerful, user-friendly operation, optional to receive data through the U disk or network.

6: Imported Lei Sai drive and motor, the power is large, the processing speed is fast, the operation is stable, the noise is extremely low.

7: High-power spindle, constant power, low noise, super cutting force, greatly improve work efficiency.

8: High-precision linear orbit, stable operation, high precision, stable support, and extend the life of the machine.

7: The Z-axis adopts imported industrial-grade ball screw, which is accurate in positioning and makes the machining effect more perfect.

8: Energy-saving vacuum adsorption table function and dust removal device make you more environmentally friendly.

9: An independent control cabinet control system, the operation is more convenient. |

| Technical Parameters |

| Working Area | 1300x2500x200mm |

| Table Surface | vacuum table |

| Machine body | Thick, strong and high quality |

| X, Y-axis driving way | Rack and Pinion /Linear square guide rails |

| Z-axis driving way |

Ball screw Linear square guide rail and blocks |

| Inverter | Fuling |

| Working Voltage |

AC380V/50-60Hz/3PH AC220V/50-60Hz/Single or 3 phase |

| Command Language | G Code |

| Control system |

DSP, NC studio, Mach 3 |

| Computer Interface | USB |

| X, Y Resolution | < 0.01mm |

| Software Compatibility | Type3/ Artcam Software) |

| Temperature | 0°-45° |

| Relative Humidity | 30%-75% |

| Lubrication system | Oil Lubrication System |

| PS: All the working area and specifications can be customized according to your requests |

| Product standard |

| Engraving machine application |

|

1. Wood furniture industry Doors; Cabinets; Tables; Chairs. Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards and so on. 2. Advertising industry Signage; Logo; Badges; Display board; Meeting signboard; Billboard Advertising filed, sign making, acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making. 3. Die industry A sculpture of copper, aluminum, iron, and other metal molds, as well as artificial marble, sand, plastic sheeting, PVC pipe, and another non-metallic mold. 4. Artwork and Decoration woodcrafts; gift box; jewelry box 5. Others Relief sculpture and 3D engraving and Cylindrical object. |

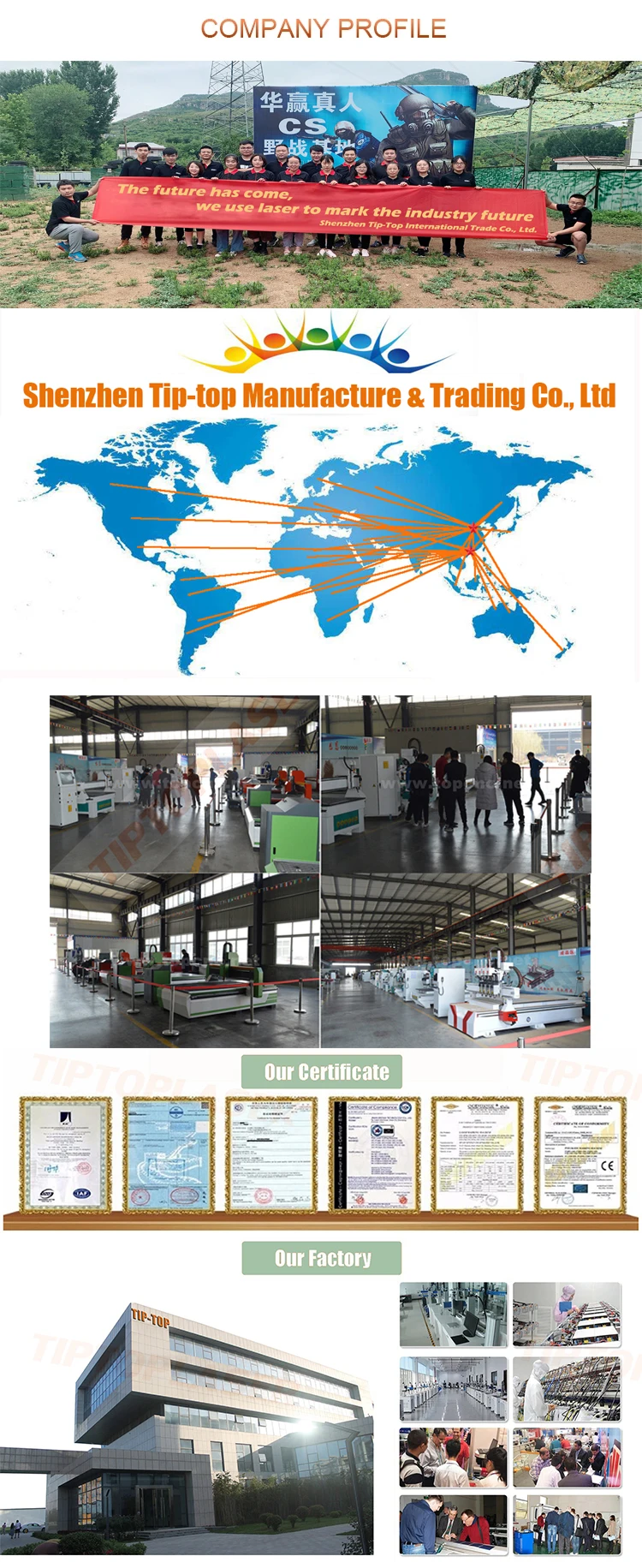

| Engraving machine company |

| Shenzhen Tip-Top Manufacture & Trading Co., Ltd Is specialized in r&d and design the equipment of various types of engraving machine, independent single head, double-headed independently, three axes, four-axis and so on. Carved stone machine factory, wood engraving machine, advertising engraving machine, foam mold engraving machine, the process of automatic tool change, multi-function processing center, etc., marking machine, welding machine and so on factory direct sales. Quality assurance, affordable, welcome to our company on-the-spot investigation. |

| Engraving machine transportation |

|

Packaging Details: 1. Outside package: Standard marine export plywood case. 2. Inner package: Three layers in total; EPE pearl cotton film+PE stretchy film. Improved package, much more strong and environmental protection. We can also make a package according to your requests.

Delivery Detail: Shipped in 5-10 working days after payment. |

| Company Services |

| Our after-sales service: 1) 3years quality guaranty, the machine with main parts(excluding the consumables)shall be changed free of charge if there is any problem during the warranty period. 2) Free training course at our plant. 3) We will provide the consumable parts at an agency price when you need replacement. 4) 24 hours online service each day, free technical support. 5) The machine has been adjusted before delivery |

| Engraving machine FAQ |

|

Q1: I knew nothing about this machine, what kind of machine I should choose? Q2: When I got this machine, but I did not know how to use it. What should I do? Q3: If some problems happened to this machine during the warranty period, what should I do? Q4: What is the MOQ? |

Reviews

There are no reviews yet.