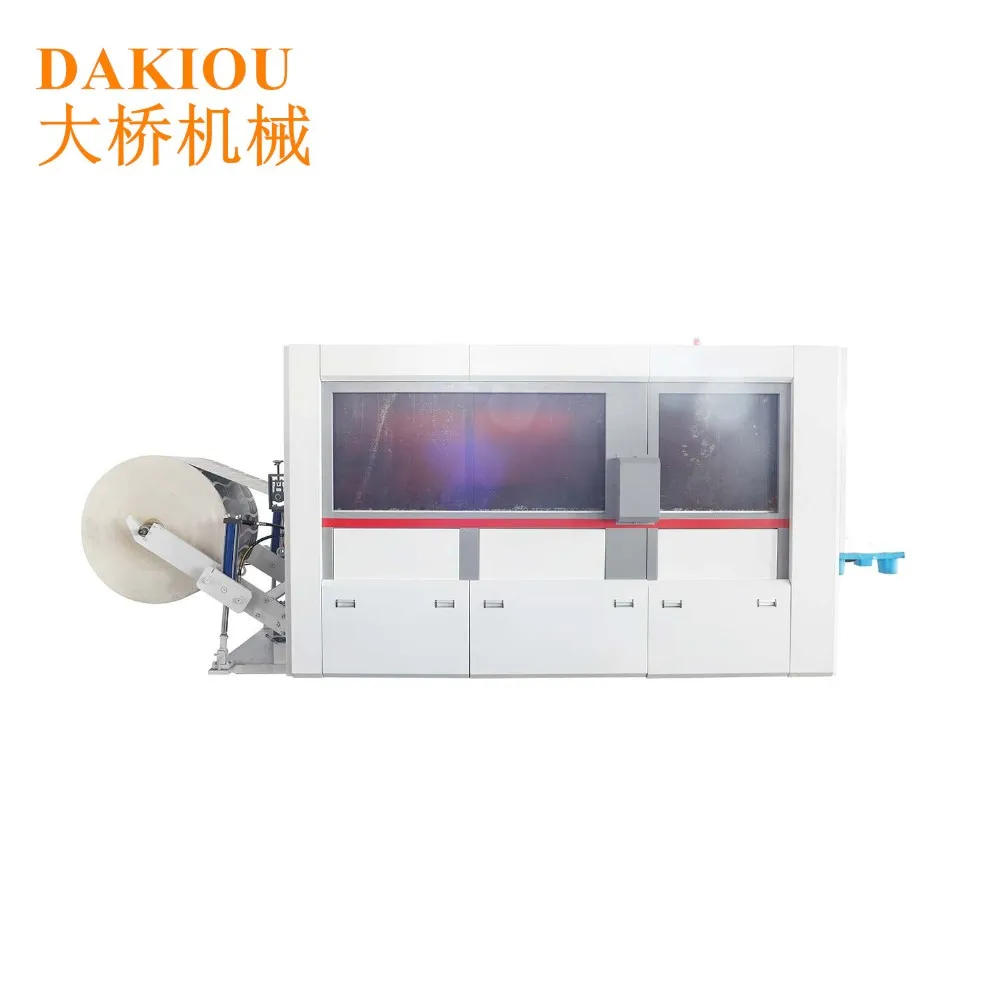

DAKIOU HBJ-D800/1200 machine for hamburg mini speaker box making , china top manufacture with CE standard

ر.س184,380.14

DAKIOU HBJ-D800/1200 PAPER CARTON ERECTING MACHINE

HBJ-D800/1200 is an ideal choice to produce hamburger boxes,chips boxes,takeout container,etc.

|

MODEL

|

HBJ-D800

|

HBJ-D1200

|

||

|

Speed

|

50-180pcs/min

|

80-320pcs/min

|

||

|

Material

|

200-600g/㎡ white cardboard paper;corrugated paper;thickness:1.5mm

|

|||

|

Power source

|

380V,50HZ

|

|||

|

Total power

|

5KW

|

6.25KW

|

||

|

Size range

|

L:100-450mm

W:100-600mm

H:15-200mm

Degree:5°-40°

|

|||

|

Packaging size

|

3600*1400*1700mm

|

3600*1850*1700mm

|

||

|

Weight

|

1800kgs

|

2800kgs

|

||

|

Other size can be customized

|

||||

|

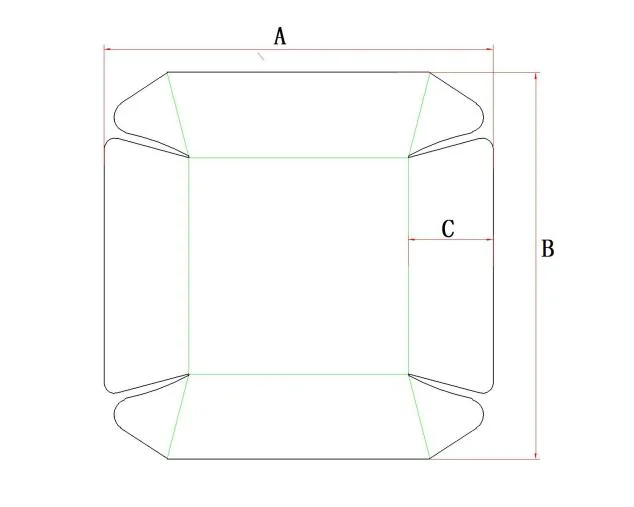

A

|

100-540mm

|

|

B

|

100-450mm

|

|

C

|

15-200mm

|

|

A

|

100-400mm

|

|

B

|

100-435mm

|

|

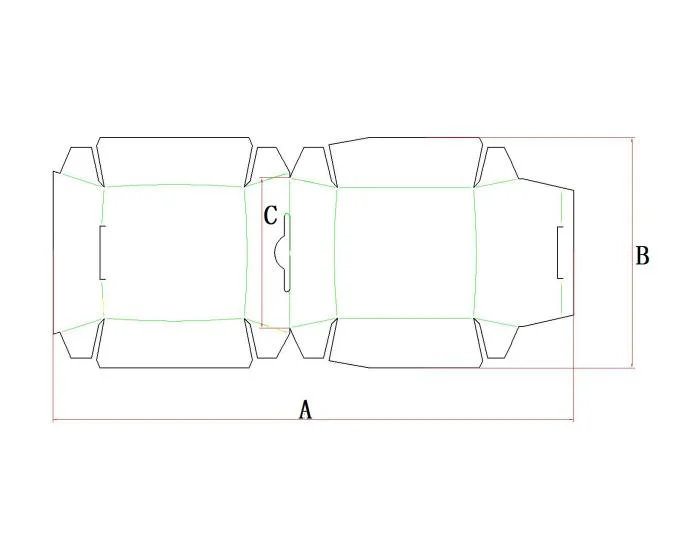

A

|

100-600mm

|

|

B

|

100-450mm

|

|

C

|

80-220mm

|

|

A

|

100-450mm

|

|

B

|

100-450mm

|

|

C

|

15-200mm

|

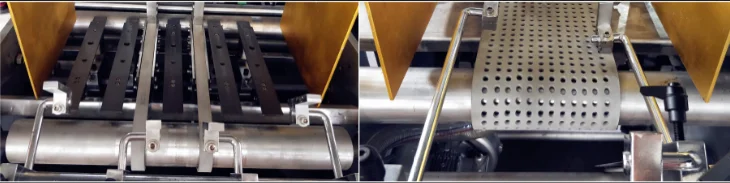

1.To improve the feeding paper stability and change molds more convenient. We use wider belt instead of two narrow belts. Narrow belt is easily abraded by papers. Also you should adjust the distance of two belts when you change the molds. For wide paper, it is more endurable and don’t need be adjusted.

2.Automatic glue system is controlled by reduce motor from Taiwan. Glue point we use sponge point, which is easy to cut the shape to fit with different products needs.

3.It adapts counting paper tape equipment to count product quickly and accurately.

4.In order to feed paper more automatically, we use both PLC operations with photoelectric sensor and servo motor to control the paper feeding part. It has two advantages.

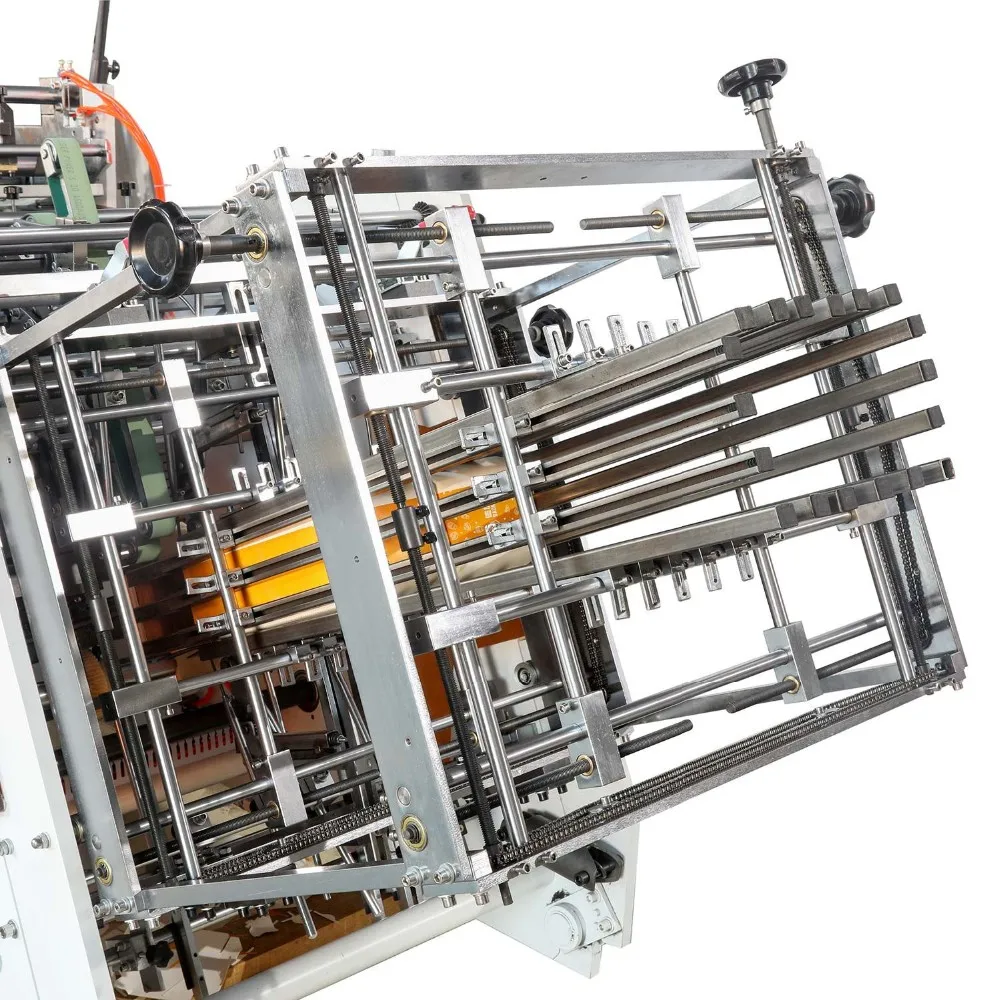

5.The frame of collecting box is separated into three parts, each part can be opened. It is easier for changing molds or repairing.

6.Nylon and wooden molds

A list of samples

We are Manufacturer…

1.Q:Where is your factory? How can I get there?

A: We are located in Ruian City Wenzhou, Zhejiang Province.

To Wenzhou Longwan airport by Air, from Shanghai is about 45mins, from Guangzhou is about 1hr 50mins and from Hongkong is about 2hrs. We will pick up you in the airport.

2.Q:Can your machine be customized?

A: Your better improvement suggestions are highly appreciated. Almost all of our products can be customized, including the sizes, color, logo, package and so on.

3.Q :What’s the OLD(order lead time)?

A: For our standard model machines is about 30days after receiving your deposit.

4. Q: How about your package?

A: Our machines are well wrapped by plastic film to be water proof first, then loading and fixing in a plywood case. If by FCL(full container loading) we might use the wooden pallet with plastic film wrapping, without plywood case.

DAKIOU PACKAGING MACHINERY CO.,LTD

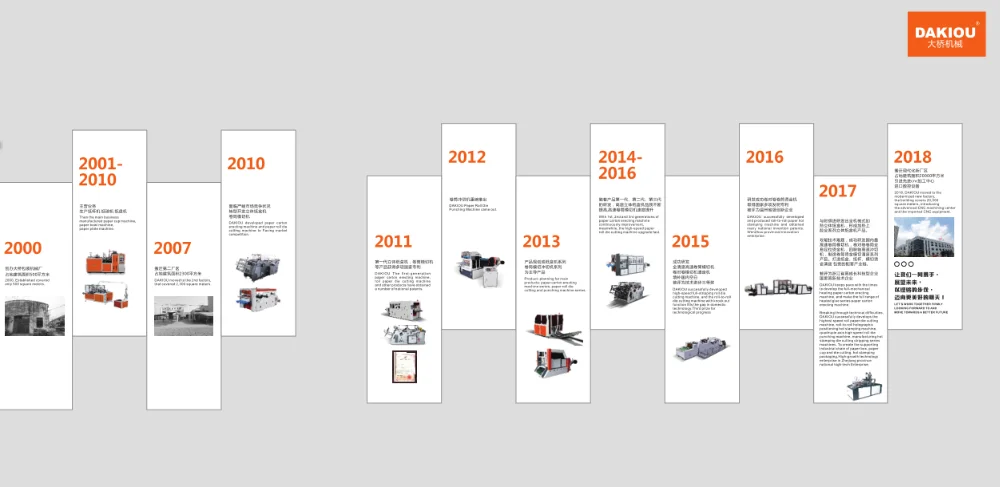

Ruian Daqiao packaging machinery co.,ltd(DAKIOU),as a developer and manufacturer of carton erecting,paper cup,roll die cutting and other paper packaging machines,Dakiou looks back on extensive expensive and fast develop spped in this field.Start from 2002,high performance models have evolved thanks to the commitment and know-how of our employees,intensive research and development,and the steady exchange with our customers on their needs and ideas.

Our company successfully certified by IS09001:2008 and products are approved CE certificate.We offer 360°service from advice to assembly,know-how meet technology for global customers.

PY series high speed roll paper die-cutting machine is an ideal and professional machine in die-cutting,creasing,embossing and full-stripping various PE coated paper,normal paper,corrugating paper and plastic material.

Reviews

There are no reviews yet.