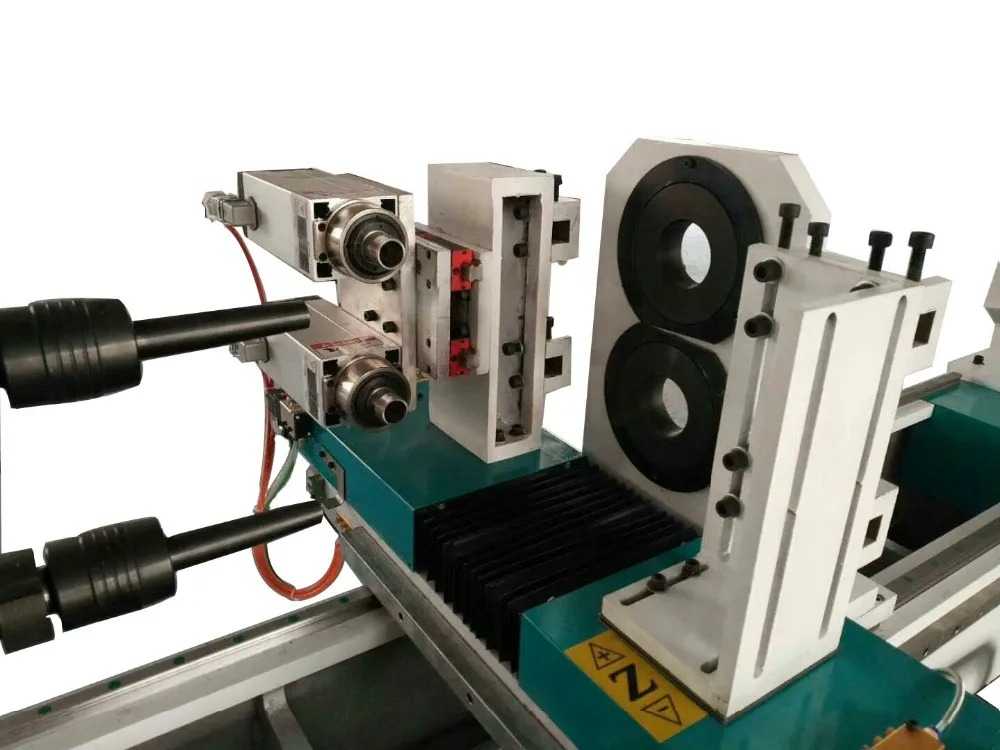

CNC Wood Lathe Two axises and Four blades Machine TJ1516 For Baseball Bats Table Chairs and Stairway Balusters

Function

This machine can be used to produce regular and irregular staircases,stairway balusters,stairway newel posts;dining table legs;end table Legs; sofa legs; bar stool legs;chair legs;chair arm posts;chair stretchers;bed rails, lamp posts,baseball bats and so on.

Double axes, double knifes and double slot-broaching, It can be use to turning and broaching two pieces of wood at the same time

1.Whole machine is welded with seamless steel structure, which is high temperature annealing and vibrating stress relief, machine weight up to 1600kgs to make sure the lathe body stabilized and never deformed.

2. Special used for wood turning and wooden cylinder engraving, for irregular table legs, stair railing (banisters), etc.

3.Adopting advanced Tianjiao Control system which is easy for operating even without a computer

4. Adopt Taiwan TBI ball screw and HIWIN helical square guide rail with high precision and longevity.

5. Compatible with several CAD/CAM design software

6. Rotating speed can be adjusted by inverter also you can see speed on control cabinet panel

7. One time tool setting to finish the whole work piece.

8.Two pieces wood can be turning,broaching with one machine by high speed at the same time.

Choose one axis and one knife to working also

Servo Motor

Three-phase asynchronous motor

Air cooling spindle

DSP handhold control system

Control cabinet

|

Item

|

Specification

|

||||

|

Max processing length

|

1500mm(can custom 2000/2500/3000mm)

|

||||

|

Max turning diameter

|

1600mm

|

||||

|

Air pressure

|

0.6-0.8Mpa

|

||||

|

Powersupply

|

AC 380V 3 phase 50HZ/60HZ (CAN CUSTOM 220V)

|

||||

|

Max feed rate

|

200cm/min

|

||||

|

Min setting unit

|

0.01cm

|

||||

|

Transimission type

|

ballcsrew for X Z axes, gear for Y axis

|

||||

|

Duider

|

Taiwan Hiwin orbit

|

||||

|

Taiwan Hiwin orbit

|

Taiwan Hiwin orbit

|

||||

|

Taiwan Hiwin orbit

|

4 KW

|

||||

|

Cutter material

|

super hard alloy

|

||||

|

Control system

|

DSP control system

|

||||

|

Motor

|

stepper motor

|

||||

|

Inverter

|

Best inverter

|

||||

|

Driver

|

YaKo driver

|

||||

|

Drawing Software

|

Auto CAD

|

||||

Stair railing Baseball bat

You Qcan tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q2: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by “Team viewer”online, with telephone or Skype explain.

Q3: Can you customize the machine for me?

Yes, we provide customized solution, but considering the cost, we will recommend the

standard configuration to you first.

Q4: What is the guarantee? In case the machine break down?

The machine has 1 year guarantee, fail parts will be replaced for free if the machine under

” normal operation”.

Q5: How about the documents after shipment?

We will send all the documents by air after shipment. Including packing list, commercial

invoice, B/L, and other certificates required by clients.

Q6: Delivery time?

For standard machine, it would be 7-10 working days; for non-standard machine, it would be 20 – 30 working days.

Q7: How is the payment?

Normally we accept T/T or L/C, if you like other terms, tell us in advance.

Q8: Do you arrange the shipment for me?

For FOB or CIF price, we will arrange shipment for you, for EXW price, you should arrange

the shipment by yourself.

Q9: How is the packing?

Step1: water proof wrapping film with foam protection in each corner.

Step2: Solid seaworthy wood box package with steel belt.

Step3: Save space as much as possible for container loading.

12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong

with the machine, you will get spare part for free. Out of 12 months, you willget spare parts at cost price.

You will also get technical support and service all the lifetime.

Technical support:

1. Technical support by phone, email or Skype around the clock.

2. Friendly English version manual and operation video CD disk.

3. Engineer available to service machinery overseas.

After sales services:

Normal machine is properly adjusted before dispatch. You will be able to use the machineimmediately after received machine.

Besides, you will be able to get free training advice towards our machine in our factory. You willalso get free suggestion and consultation, technical support and service by email/fax/tel etc

● the foundation construction unit shall provide the quality certificate of the equipment foundation (such as ratio, maintenance, strength).

● if there is doubt about the strength of the equipment foundation, the strength of the foundation can be re-measured by springback instrument or steel ball impact method.

● check the appearance of the foundation

● check the position and geometry of the foundation

Preloading test of heavy equipment base is to prevent the heavy equipment due to the uneven subsidence of the foundation after installation equipment installation is unqualified preloaded pressure not less than equipment running at full capacity (the sum of the force on the basis of equipment), the heavy equipment can be installed level requirement is not high, only when the equipment test run on the basis of settlement observation.

We have our own patented technology and research team,can provide you with professional and timely technical support.We are trustworthy.

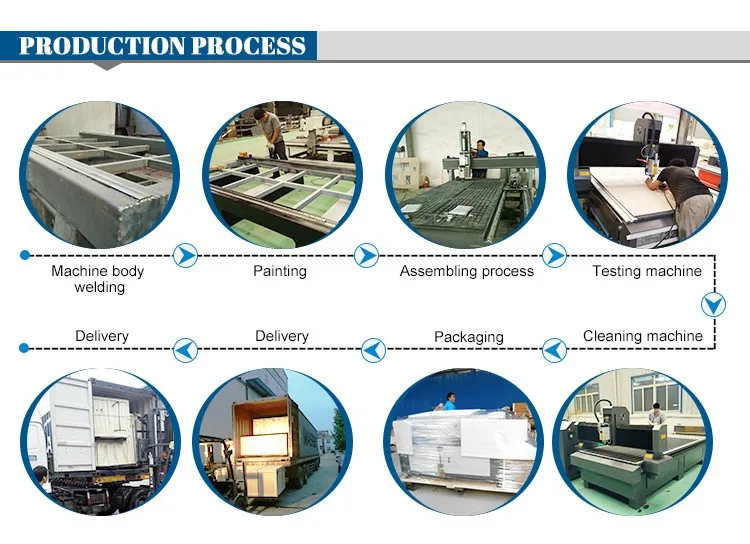

2.Painting

3.Assembling process

4.Testing machine

5.Cleaning machine

6.packing

7.delivery

8.transport

Reviews

There are no reviews yet.