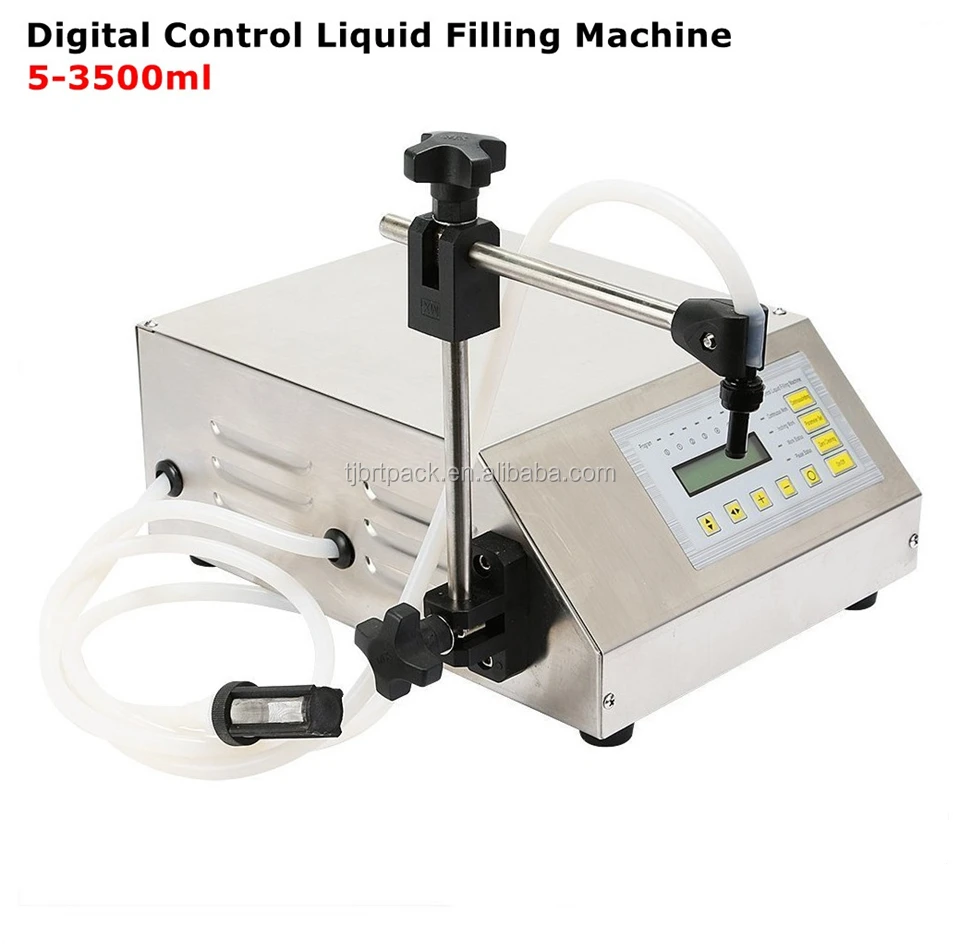

china factory price Small Liquid Filler beer bottle filling machine

Product Application

This Updated GFK series numerical control liquid filling machine uses micro-computer to control the mini-pump on filling time and the rotation rate of electric motor so that the machine can fill the liquid fluently and at high accuracy. Separated with the electric motor,the pump is made of a variety of anti-corrosion imported material. There is no mechanical metal part or abrasion inside the pump.

This numerical control liquid filling machine is compact and portable. The casing uses stainless steel so it is durable and easy to clean. The machine has a self-prime pump that can suck in the liquid from your container and then output via the nozzle. It can be used to fill many different types of clear thin liquid,including water, olive oil, fuel, drinks, vinegar, milk etc.

Liquid suitable: low viscous liquid like water, wine, solutions etc.

Liquid unsuitable: very thick liquid (sauce,detergent etc), or liquid containing small particles.

Main Features

Automatic counting function, effectively control filling quantity

Import single-chip microcomputer control, high efficiency, low power consumption

LCD display, touch screen is very easy to operate

Filling Accuracy is high, precise volume

Wide Voltage range

Working performance is stable and can be used for long time

Self-suck function, don’t need to pour

The pump can stand acid and alkali

Anti-dripping design

Reasonable design, made of stainless steel, meet GMP requirement

Speed Parameter Range: 1-9, Filling Time Range: 0.01-99.99s, Interval time Range: 0.01-99.99s

Save up to 6 sets of parameters for different-sized bottles and can choose from easily

Widely used in medical, chemistry, food, beverage, oil, and cosmetics, etc.

Suitable for filling low-viscous liquid without pellets

The pump can stand oil, heat, acid, alkali, abrasion and chemical products

Integrates the advantage of self-suck pump and chemical pump

Self suck, heat protect, stable working and continuous idle or load operate for long time

|

TECHINICAL

|

||

|

Voltage

|

220V/110V

|

|

|

Power

|

30W

|

|

|

Max Flow Rate:

|

3.2L/min

|

|

|

Filling Volume Range

|

5-3500ML

|

|

|

Memory Function without Electricity

|

Available

|

|

|

Diameter of Filling Nozzle:

|

Φ 8mm

|

|

|

Suitable Soft Tube

|

17#(interior diameter: 6.4mm, thickness: 1.6mm, max pressure0.24Mp)

|

|

|

Note

|

Different liquid needs to choose different material of tube. The tube provided by us is silicone tube.

|

|

1. Installation

Take the plastic filling nozzle out and install it in the feeding tube. (Notice the triangle head connects the discharge tube). Take out the filling-head stand and install it on the left of the machines as photo3 shows. Put the filling head in the clip and tighten it by socket wrench.

Connect the pedal switch with machine, and put the tube with filter below the liquid level inside the storage rank. The position of tank should be lower than the machine. Start to test the machine after all is ready.

2. Turn on

Switch on the machine, the LCD screen will show welcome words and the machine will be under standby status after 3 seconds. As photo4 shows, the screen shows filling quantity at the top left corner, filling speed at bottom left corner, once filling time at the top right corner, interval time at bottom right corner.

3. Adjustment

When the machine is under working status, other buttons can’t work. You can adjust the parameter after press the on/off button to let the machine under pause status.

4. Measurement Proofreading

This procedure is to check out if there is water coming out from the nozzle. By adjusting the filling time and speed to meet the requirement. The normal work can be carried out after the measurement proofreading is done.

Kindly note: The manufacturer will not be responsible for any damage due to improper operation. This kind of risk should be taken by the users. Strictly abiding by the manual book is a part of operation requirement.

Reviews

There are no reviews yet.